Chapter: Electrical machines : Single Phase Induction Motor and Special Machines

Types of Split-Phase Induction Motors

TYPES OF SPLIT-PHASE INDUCTION MOTORS

1. Resistance-start, induction-run motors

2. Capacitor-start, induction-run motors

3. Capacitor-start, capacitor-run motors

4. Shaded pole motors.

1. RESISTANCE-START, INDUCTION-RUN MOTORS

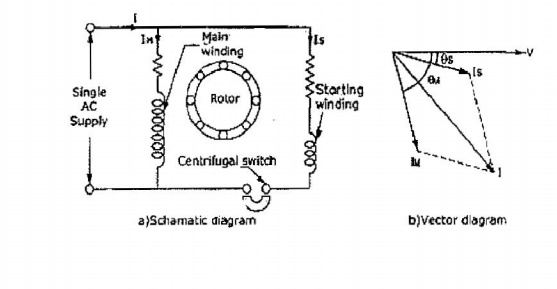

As the starting torque of this type of motor is relatively small and its starting current is high, these motors are most commonly used for rating up to 0.5 HP where the load could be started easily. The essential parts are shown in Fig:

Main winding or running winding.

Auxiliary winding or starting winding

Squirrel cage type rotor.

Centrifugal switch.

CONSTRUCTION AND WORKING

The starting winding is designed to have a higher resistance and lower reactance than the main winding. This is achieved by using small conductors in the auxiliary winding than in the main winding. The main winding will have higher inductance when surrounded by more iron, which could be made possible by placing it deeper into the stator slots, it is obvious that the current would split as shown in Fig: (b).

The starting current "I" start will lag the main supply voltage "V" line by 15 degree and the main winding current. "I" main lags the main voltage by about 80 degree. Therefore, these currents will differ in time phase and their magnetic fields will combine to produce a rotating magnetic field.

When the motor has comeupto about 75 to 80% of synchronous speed, the starting winding is opened by a centrifugal switch and the motor will continue to operate as a single phase motor.

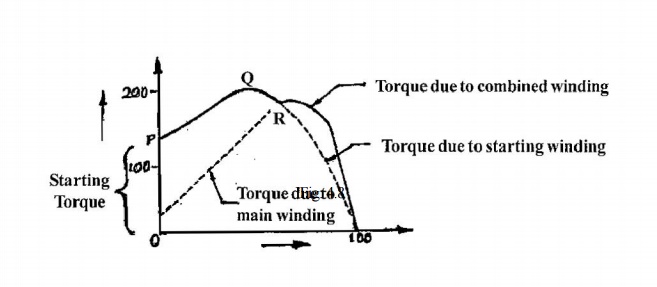

CHARACTERISTICS

At the point where the starting winding is disconnected, the motor develops nearly as much torque with the main winding alone as with both windings connected. This can be observed from, the typical torque-speed characteristics of this motor, as shown in Fig:.

The direction of rotating of a split-phase motor is determined by the way the main and auxiliary windings are connected. Hence, either by changing the main winding terminals or by changing the starting winding terminals, the reversal of direction of rotating could be obtained.

APPLICATIONS

These motors are used for driving fans, grinders, washing machines.

2. CAPACITOR-START, INDUCTION-RUN MOTOR

A drive which requires a large starting torque may be fitted with a capacitor-start, induction-run motor as it has excellence starting torque as compared to the resistance-start, induction-run motor.

CONSTRUCTION AND WORKING

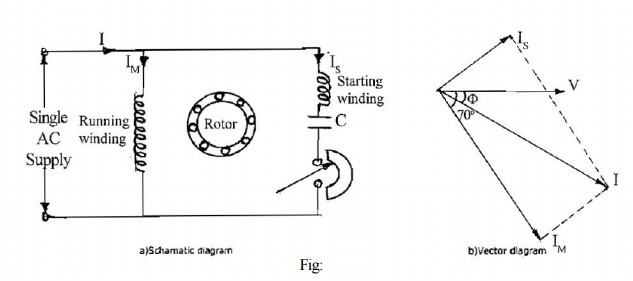

Fig: (a) shows the schematic diagram of a capacitor-start, induction-run motor. As shown, the main winding is directly connected across the main supply whereas the starting winding is connected across the main supply through a capacitor and centrifugal switch.

Both these windings are placed in a stator slot at 90 degree electrical apart, and a squirrel cage type rotor is used.

As shown in Fig: (b), at the time of starting the current in the main winding lags the supply voltages by 90 degrees, depending upon its inductance and resistance. On the other hand, the current in the starting winding due to its capacitor will lead the applied voltage, by say 20 degrees.

Hence, the phase difference between the main and starting winding becomes near to 90 degrees. This in turn makes the line current to be more or less in phase with its applied voltage, making the power factor to be high, thereby creating an excellent starting torque.

However, after attaining 75% of the rated speed, the centrifugal switch operates opening the starting winding and the motor then operates as an induction motor, with only the main winding connected to the supply.

As shown in Fig: 4.9(b), the displacement of current in the main and starting winding is about 80/90 degrees, and the power factor angle between the applied voltage and line current is very small. This results in producing a high power factor and an excellent starting torque, several times higher than the normal running torque as shown in Fig:

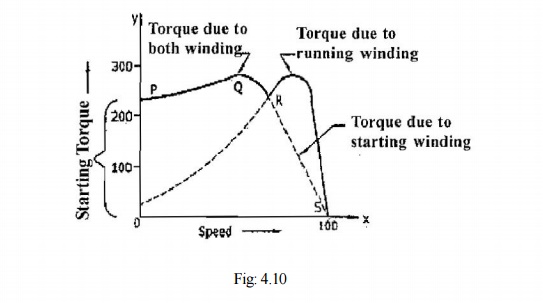

CHARACTERISTICS

The torque-speed characteristics of this motor is shown in Fig:.

In order to reverse the direction of rotation of the capacitor-start, induction-run motor, either the starting or the main winding terminals should be changed.

This is due to the fact that the direction of rotation depends upon the instantaneous polarities of the main field flux and the flux produced by the starting winding. Therefore, reversing the polarity of one of the field will reverse the torque.

APPLICATIONS

Due to the excellent starting torque and easy direction-reversal characteristics,

Used in belted fans,

Used in blowers dryers,

Used in washing machines,

Used in pumps and compressors.

3. CAPACITOR-START, CAPACITOR-RUN MOTORS

As discussed earlier, one capacitor-start, induction-run motors have excellent starting torque, say about 300% of the full load torque and their power factor during starting in high.

However, their running torque is not good, and their power factor, while running is low. They also have lesser efficiency and cannot take overloads.

CONSTRUCTION AND WORKING

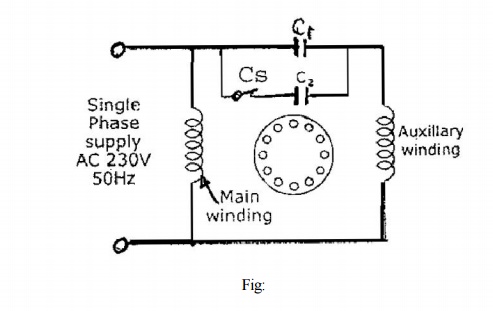

The aforementioned problems are eliminated by the use of a two valve capacitor motor in which one large capacitor of electrolytic (short duty) type is used for starting whereas a smaller capacitor of oil filled (continuous duty) type is used for running, by connecting them with the starting winding as shown in Fig:. A general view of such a two valve capacitor motor is shown in Fig:.

This motor also works in the same way as a capacitor-start, induction-run motor, with exception, that the capacitor C1 is always in the circuit, altering the running performance to a great extent.

The starting capacitor which is of short duty rating will be disconnected from the starting winding with the help of a centrifugal switch, when the starting speed attains about 75% of the rated speed.

CHARACTERISTICS

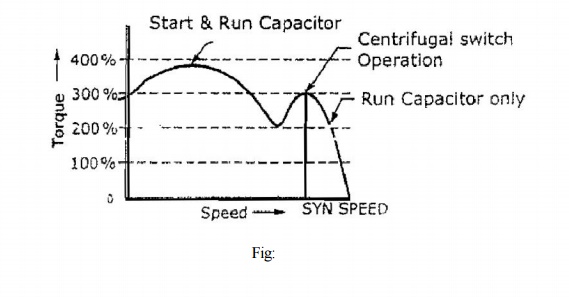

The torque-speed characteristics of this motor is shown in Fig:.

This motor has the following advantages:

• The starting torque is 300% of the full load torque

• The starting current is low, say 2 to 3 times of the running current.

• Starting and running power factor are good.

• Highly efficient running.

• Extremely noiseless operation.

• Can be loaded upto 125% of the full load capacity.

APPLICATIONS

• Used for compressors, refrigerators, air-conditioners, etc.

• Higher starting torque.

• High efficiency, higher power factor and overloading.

• Costlier than the capacitor-start — Induction run motors of the same capacity.

Related Topics