Chapter: Mechanical : Metrology and Measurements : Concepts of Measurement

Introduction to Dimensional And Geometric Tolerance

INTRODUCTION TO

DIMENSIONAL AND GEOMETRIC TOLERANCE

General Aspects

In the design and

manufacture of engineering products a great deal of attention has to be paid to

the mating, assembly and fitting of various components. In the early days of

mechanical engineering during the nineteenth century, the majority of such components

were actually mated together, their dimensions being adjusted until the

required type of fit was obtained. These methods demanded craftsmanship of a

high order and a great deal of very fine work was produced. Present day

standards of quantity production, interchangeability, and continuous assembly

of many complex compounds, could not exist under such a system, neither could

many of the exacting design requirements of modern machines be fulfilled

without the knowledge that certain dimensions can be reproduced with precision

on any number of components. Modern mechanical production engineering is based

on a system of limits and fits, which while not only itself ensuring the

necessary accuracies of manufacture, forms a schedule or specifications to

which manufacturers can adhere.

In

order that a system of limits and fits may be successful, following conditions

must

be fulfilled:

1. The

range of sizes covered by the system must be sufficient for most purposes.

2. It

must be based on some standards; so that everybody understands alike and a

given dimension has the same meaning at all places.

3. For

any basic size it must be possible to select from a carefully designed range of

fit the most suitable one for a given application.

4. Each

basic size of hole and shaft must have a range of tolerance values for each of

the different fits.

5. The

system must provide for both unilateral and bilateral methods of applying the

tolerance.

6. It

must be possible for a manufacturer to use the system to apply either a

hole-based or a shaft-based system as his manufacturing requirements may need.

7. The

system should cover work from high class tool and gauge work where very wide

limits of sizes are permissible.

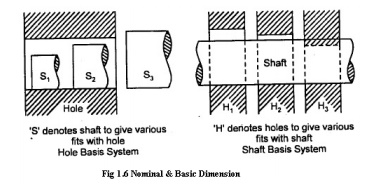

Nominal Size and Basic

Dimensions

Nominal size: A

'nominal size' is the size which is used for purpose of general identification.

Thus the nominal size of a hole and shaft assembly is 60 mm, even though the

basic size of the hole may be60 mm and the basic size of the shaft 59.5 mm.

Basic dimension: A

'basic dimension' is the dimension, as worked out by purely design

considerations. Since the ideal conditions of producing basic dimension, do not

exist, the basic dimensions can be treated as the theoretical or nominal size,

and it has only to be approximated. A study of function of machine part would

reveal that it is unnecessary to attain perfection because some variations in

dimension, however small, can be tolerated size of various parts. It is, thus,

general practice to specify a basic dimension and indicate by tolerances as to

how much variation in the basic dimension can be tolerated without affecting

the functioning of the assembly into which this part will be used.

Definitions

The

definitions given below are based on those given in IS: 919

Shaft: The

term shaft refers not only to diameter of a circular shaft to any external

dimension on a component.

Hole: This

term refers not only to the diameter of a circular hole but to any internal

dimension on a component.

Basics

of Fit

A fit or limit system consists of a

series of tolerances arranged to suit a specific range of sizes and functions,

so that limits of size may. Be selected and given to mating components to

ensure specific classes of fit. This system may be arranged on the following

basis:

1. Hole

basis system

2. Shaft

basis system.

Hole

basis system:

'Hole basis system' is one in which the

limits on the hole are kept constant and the variations necessary to obtain the

classes of fit are arranged by varying those on the shaft.

Shaft

basis system:

'Shaft basis system' is one in which the limits on

the shaft are kept constant and the variations necessary to obtain the classes

of fit are arranged by varying the limits on the holes. In present day

industrial practice hole basis system is used because a great many holes are

produced by standard tooling, for example, reamers drills, etc., whose size is

not adjustable. Subsequently the shaft sizes are more readily variable about

the basic size by means of turning or grinding operations. Thus the hole basis

system results in considerable reduction in reamers and other precision tools

as compared to a shaft basis system because in shaft basis system due to

non-adjustable nature of reamers, drills etc. great variety (of sizes) of these

tools are required for producing different classes of holes for one class of

shaft for obtaining different fits.

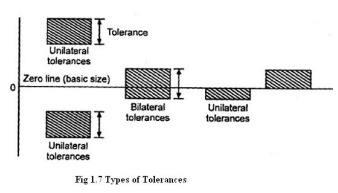

Systems of Specifying

Tolerances

The tolerance or the error permitted in manufacturing

a particular dimension may be allowed to vary either on one side of the basic

size or on either side of the basic size. Accordingly two systems of specifying

tolerances exit.

1. Unilateral

system

2. Bilateral

system.

In the unilateral

system, tolerance is applied only in one direction

+ 0.04 -0.02

Examples: 40.0

or 40.0

+ 0.02 -0.04

In the bilateral system

of writing tolerances, a dimension is permitted to vary in two directions.

+ 0.02 Examples: 40.0

- 0.04

Related Topics