Chapter: Special Electrical Machines : Synchronous Reluctance Motors

Vernier Motors

VERNIER MOTORS

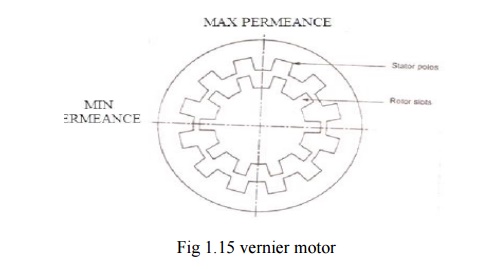

A Vernier

motor is an unexcited (or reluctance Type) inductor synchronous motor. It is

also named because it operates on the principle of a vernier. The peculiar

feature of this kind of motor is that a small displacement of the rotor

produces a large displacement of the axes of maximum and minimum permeance.

When a rotating magnetic field is introduced in the air gap of the machine,

rotor will rotate slowly and at a definite fraction of the speed of the

rotating field.

This

rotating field can be produced either by feeding poly phase current to the

stator winding or by exciting the stator coil groups in sequence. AS the rotor

speed steps down from the speed of the rotating field, the motor torque steps

up. A vernier motor works as an electric gearing. This kind of motor is

attractive in applications which require low speed and high torque and where

mechanical gearing is undesirable.

1. Principle of operation

The

stator of a vernier motor has slots and a distributed winding just like the

stator of an ordinary poly phase induction motor. The rotor is a slotted iron

core without winding. A 2 – pole machine with 12 stator slots and 10 rotor

slots.

The

stator and rotor teeth are facing each other in the vertical axis. The stator

teeth are facing rotor slots in the horizontal axis. At this position

therefore, the maximum permeance is along the vertical axis and the minimum

permeance is along the horizontal axis. When then rotor is rotated one half of

its slot pitch, the rotor slots will face stator teeth in the vertical axis.

The rotor and stator teeth will face each other in the horizontal axis. The

axis of maximum permeance is now horizontal and the axis of minimum permeance

is now vertical. Thus the rotor movement of one –half rotor slot pitch results

in a 90 degree displacement of the permeance axes.

Suppose

that a magnetic field is rotating in the machine. Whenever the rotating field rotates

90 degrees, the rotor will rotate one half of its slot pitch. When the rotating

field completes one revolution, the rotor will rotate through an angle

corresponding to two rotor slot pitches.

2. Air – Gap permeance

Distribution

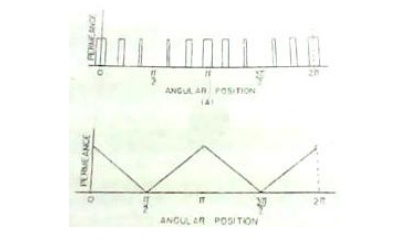

The

fluxes in the air gap are assumed all in the radial direction. The permeance of

air space between stator and rotor at any location is inversely proportional to

the radial length of air space at that location. The stator and rotor slot

depth are much larger in comparison with air gap length, the permeance of

airspace can be considered as zero, where stator tooth surface is facing rotor

tooth surface. The width of rectangular blocks is the widths of overlap between

the stator and the rotor teeth. These widths of overlap vary linearly from a

maximum and back to a minimum. The area of overlap is reduced a constant amount

for each successive stator tooth until a minimum is reached.

The

permeance distribution curve is not convenient to use because it cannot be

represented by simple mathematical function. When the rotor rotates, this

permanence wave rotates at a much faster speed. Five times the rotor speed for

the machine. The axes at which maximum and minimum permeance occur are tge

direct and quadrature axes respectively of the vernier motor.

3. Design of Vernier Motor

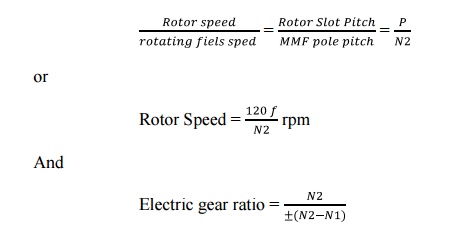

In a poly

phase reluctance motor the rotor has the same number of poles as the stator

mmfwave.Similarly in a vernier motor the air gap permeance wave should have the

same number of poles as the stator mmf wave. The number of stator and rotor

slots has the following relation

N1 = N2 ±

P

Where

N1 –

Number of Stator Slots

N2 –

Number of Rotor Slots

P –

Number of poles of the rotating magnetic field.

When the

rotor rotates through an angle corresponding to one rotor slot pitch, the

permeance wave rotates through an angle corresponding to one pole pitch. The

pole pitch of the permeance wave is the same as the pole pitch of the stator

mmf wave, because they have the same number of poles. Also in a reluctance

machine, the speed of the permeance wave is the speed of rotating mmf.

Therefore,

The rotor

speed is independent of the number of poles of the machine when the speed of

rotating magnetic field is reduced by increasing the number of poles of the

machine. It cannot be expected that the speed of the rotor be reduced

proportionately because when P is increased the difference between N2 and N1

should also be increased, and the electric gear ratio is reduced in the inverse

proportion. Thus the rotor speed is not affected by the number of poles but

depends on the number of rotor slots.

The main

step in design is to calculate the direct and quadrature axes reactance‘s Xd

and Xq.

Xd = X1

+Xad

Xq = X1 +

Xaq

Where X1

is the stator leakage reactance and Xad and Xaq are the direct and quadrature

axes reactance of armature reaction.Xad is the ratio of the fundamental

component of reactive armature voltage, produced by the mutual flux due to the

fundamental direct axis component of armature current,Similarly Xaq is the

ratio of the fundamental component of reactive armature voltage produced by the

mutual flux due to the fundamental quadrature axis component of the armature

current, to its component under steady state conditions and at rated frequency.

Related Topics