Chapter: Special Electrical Machines : Synchronous Reluctance Motors

Construction of Synchronous Reluctance Motor

CONSTRUCTION OF SYNCHRONOUS

RELUCTANCE MOTOR

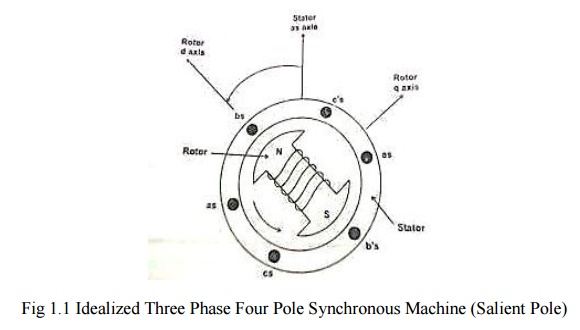

The

structure of reluctance motor is same as that of salient pole synchronous

machine as shown in fig. The rotor does not have any field winding .The stator

has three phase symmetrical winding, which creates sinusoidal rotating magnetic

field in the air gap, and the reluctance torque is developed because the

induced magnetic field in the rotor has a tendency to cause the rotor to align

with the stator field at a minimum reluctance position

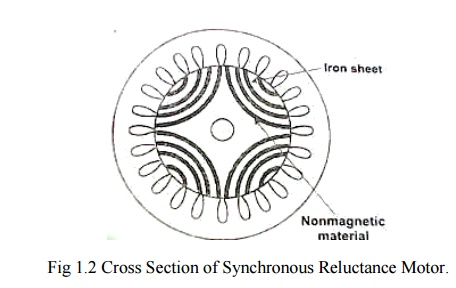

The rotor

of the modern reluctance machine is designed with iron laminations in the axial

direction separated by non-magnetic material. The performance of the reluctance

motor may approach that of induction machine. With high saliency ratio a power

factor oh 0.8 can be reached. The efficiency of a reluctance machine may be

higher than an induction motor because there is no rotor copper loss. Because

of inherent simplicity, robustness of construction and low cost.

The

synchronous reluctance motor has no synchronous starting torque and runs up

from stand still by induction action. There is an auxiliary starting winding.

This has increased the pull out torque, the power factor and the efficiency.

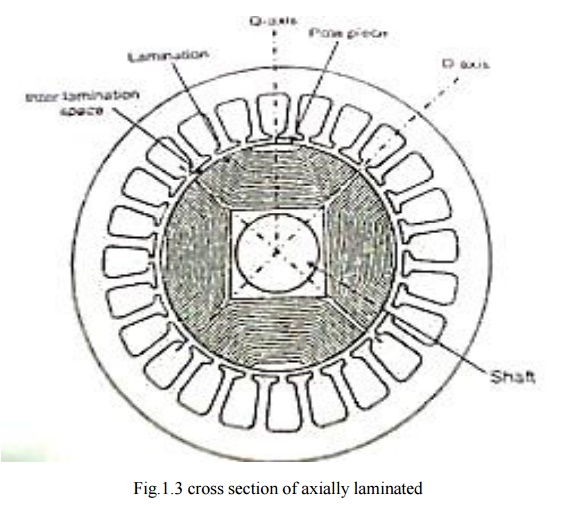

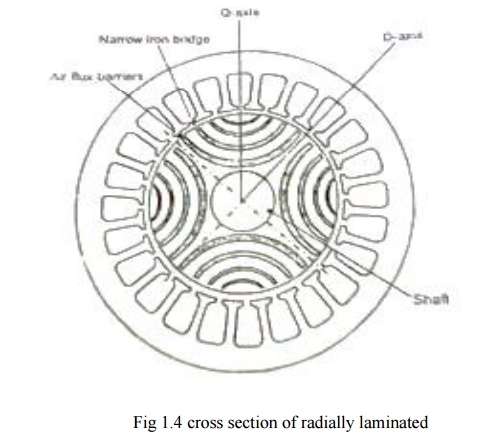

Synchronous

reluctance motor is designed for high power applications. It can broadly be

classified into

Axially

laminated and

Radially

laminated.

Reluctance

motors can deliver very high power density at low cost, making them ideal for

many applications. Disadvantages are high torque ripple (the difference between

maximum and minimum torque during one revolution) when operated at low speed,

and noise caused by torque ripple. Until the early twenty-first century their

use was limited by the complexity of designing and controlling them. These

challenges are being overcome by advances in the theory, by the use of

sophisticated computer design tools, and by the use of low-

cost

embedded systems for control, typically based on microcontrollers using control

algorithms and real-time computing to tailor drive waveforms according to rotor

position and current or voltage feedback. Before the development of large-scale

integrated circuits the control electronics would have been prohibitively

costly.

The

stator consists of multiple projecting (salient) electromagnet poles, similar

to a wound field brushed DC motor. The rotor consists of soft magnetic

material, such as laminated silicon steel, which has multiple projections

acting as salient magnetic poles through magnetic reluctance. The number of

rotor poles is typically less than the number of stator poles, which minimizes

torque ripple and prevents the poles from all aligning simultaneously—a

position which cannot generate torque.

When a

rotor pole is equidistant from the two adjacent stator poles, the rotor pole is

said to be in the "fully unaligned position". This is the position of

maximum magnetic reluctance for the rotor pole. In the "aligned

position", two (or more) rotor poles are fully aligned with two (or more)

stator poles, (which mean the rotor poles completely face the stator poles) and

is a position of minimum reluctance.

When a

stator pole is energized, the rotor torque is in the direction that will reduce

reluctance. Thus the nearest rotor pole is pulled from the unaligned position

into alignment with the stator field (a position of less reluctance). (This is

the same effect used by a solenoid, or when picking up ferromagnetic metal with

a magnet.) In order to sustain rotation, the stator field must rotate in

advance of the rotor poles, thus constantly "pulling" the rotor

along. Some motor variants will run on 3-phase AC power (see the synchronous

reluctance variant below). Most modern designs are of the switched reluctance type,

because electronic commutation gives significant control advantages for motor

starting, speed control, and smooth operation (low torque ripple).

Dual-rotor

layouts provide more torque at lower price per volume or per mass. [The

inductance of each phase winding in the motor will vary with position, because

the reluctance also varies with position. This presents a control systems

challenge.

Applications

v Some washing

machine designs.

v Control

rod drive mechanisms of nuclear reactors.

v The Dyson Digital Motor used in some

products produced by the Dyson company.

Related Topics