Chapter: Pharmaceutical Drug Analysis: Thermoanalytical Analysis

Thermometric Titrations (TT)

THERMOMETRIC TITRATIONS (T T)

1. THEORY

The thermometric titrations (TT) make use of ‘heats of reaction’ to obtain titration

curves. In usual practice, the temperature of solution is plotted against the

volume of titrant. TT is performed by allowing the titrant to flow from a

thermostated-burette directly into a solution contained in a

thermally-insulated vessel, and subsequently the observed change in temperature

of the solution is recorded precisely either during con-tinuous addition of

titrant or after every successive incremental addition. The end-point is aptly

indicated by a sharp break in the curve.

As the dielectric constant of a solvent exerts little

effect on the thermometric titrations, the latter may be employed effectively

in most non-aqueous media.

Hence, in a broader-sense TT may be utilized in a number

of reactions with greater efficacy, for in-stance : complexation,

precipitation, redox, neutralization. Further, TT can be used to titrate gases

against other gases devoid of a liquid-phase ; and to titrate liquid solutions

with gaseous reagents.

2. INSTRUMENTATION

A standard thermometric titration assembly essentially

consists of the following four vital

components, namely :

(i)

Motor-driven Burette,

(ii) Adiabatic

Titration Chamber

(iii)

Thermister Bridge Assembly, and

(iv) Recorder.

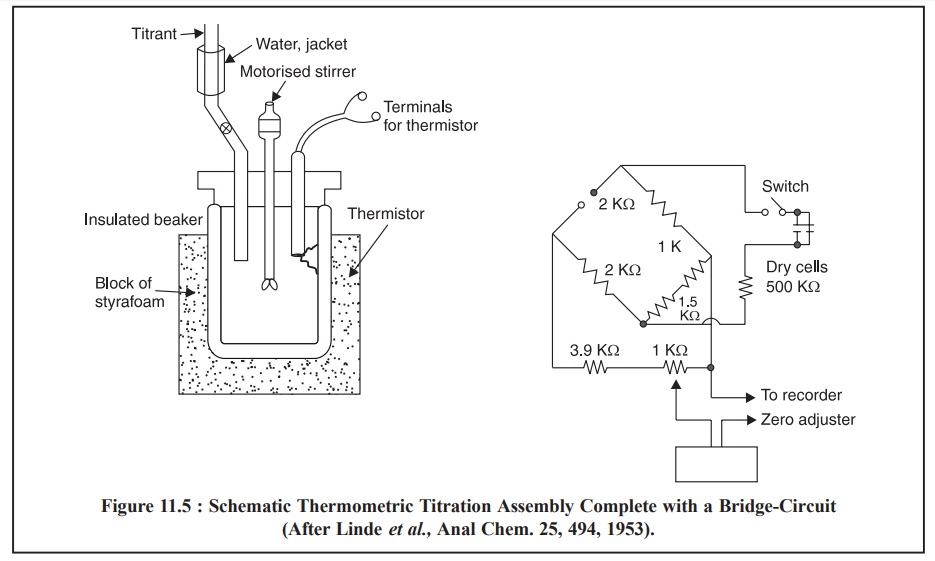

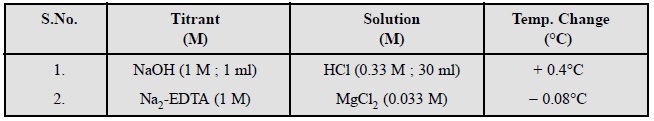

Fiaure 11.5, represents the schematic thermometric titration

assembly complete with a bridge-circuit. To minimise heat transfer losses from

the solution by its immediate surroundings, the thermometric titrations are

usually carried out in an isolated-beaker tightly closed with a stopper having

provision for a burette-tip, a motorized-glass stirrer, and a

temperature-monitoring arrangement.

Procedure :

(a) Introduce

the titrant from a burette that is duly mounted in a thermostated-water-jacket

to maintain the temperature of the titrant within ± 0.05°C,

(b)

Experimental parameters are predetermined in such a fashion such that the

volume of titrant needed for each titration must lie between 1-3 ml,

(c) Automated

device delivering reagent at a steady and constant rate of 600 µl

per minute usually permits recording,

(d)

Constant-speed motorized stirrer at 600 rpm is employed to effect uniform

mixing of solution,

(e) Variations

in temperature are measured with the help of a sensitive

thermister-sensing-element with fast response, that is sealed completely in

glass and immersed in solution,

(f) In the

course of a thermometric titration, the thermister attached to the

insulated-beaker is connected to one arm of the Wheatstone Bridge as displayed

in Figure 11.5. The values of the circuit component listed are for a thermister

having an approximate resistance of 2 KΩ

and a sensitivity of –0.04 Ω/Ω/°C

in the 25°C temperature range. Hence, an observed change of 1°C an unbalanced

potential of 15.7 mV, and

(g) The heat of reaction is

either absorbed or generated upon addition of the titrant to the beaker,

thereby unbalancing the Wheatstone Bridge caused by simultaneous variations in

the resistance (temperature) in the insulated-beaker thermister. Thus, the

bridge unbalance potential is promptly plotted by the recorder.

Note : (i) To minimise the

temperature variations between the titrant and the solution and also to obviate

volume corrections, the concentration of the titrant is invariably maintained

10–100 times higher than that of the reactant, and

(ii) To obtain optimum results, temperatures of

the titrant and the solution must be always within 0.2°C of each other before a titration is commenced.

3. METHODOLOGY

Thermometric titration curves usually represent both the

entropy and the free energy involved. The titrant is added to the solution at a

constant rate in order that the voltage output of the

thermister-temperature-transducer changes linearly with time upto the

equivalence point.

TT-method affords exact end-point due to :

(a) Coloured

solutions, and

(b) Poisoning

of Electrodes.

In usual practice it has been observed that thermometric

titrations are mostly feasible with such sys-tems that provide rates of

temperature change more than 0.01°C/second.

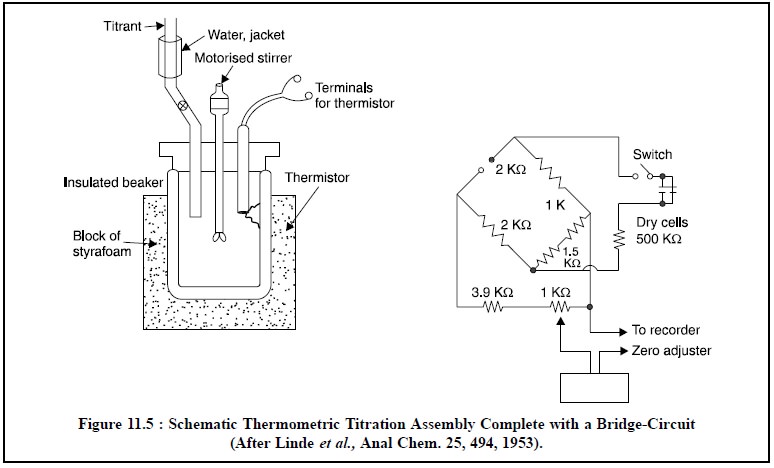

A few typical examples are cited below :

Precautions :

(i) Lower limit

of concentrations which can be titrated effectively is 0.002 M,

(ii) No

transfer of heat between the titration vessel and its immediate surroundings is

allowed, and

(iii) During

titration temperature fluctuation must not exceed 0.001°C.

4. APPLICATIONS

Various important applications of thermometric titrations

are enumerated below :

(i) Precipitation Reactions : e.g., Chloride ions (Cl–)

with Ag+ ions. Besides, phase relations have been studied extensively

in precipitation reactions.

(ii) Ion-combination Reactions : e.g., divalent cations like Ca2+,

Mg2+ with EDTA (complexometric estimation),

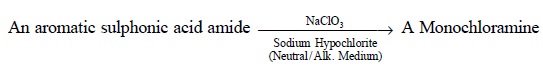

(i)

Conversion of Amides to Amines

: e.g.,

(iv) Estimation of H2O and (CH3CO)2O

concentrations in a mixture : The concentration of either of these

reactions in the presence of the other may be determined successfully by

measuring the rise in temperature taking place during the exothermic reactions

of water and acetic anhydride in gla-cial acid solution along with a trace of

perchloric acid (HClO4) acting as a catalyst, and

(v) Benzene in Cyclohexane : Benzene may be

estimated rapidly with fairly good accuracy in cyclohexane by measuring the

heat of nitration, whereby a previously prepared standard nitrating acid

mixture (benzene and cyclohexane) and the subsequent temperature rise is noted

which is a direct function of the quantity of benzene present.

Details involving various experimental parameters for the

above estimation are enumerated below :

4.1. Estimation of Benzene in Cyclohexane

Materials Required : Thermometric titration

assembly as per Figure 11.5, minus the burette; a stop-watch or timer ;

standard nitrating acid mixture [mix 2 volumes of 70% HNO3 (d = 1.41) with 1 volume of 95% H2SO4

(d = 1.82)] ; Bakelite screw-cap

bottle (4 oz. capacity) : 2.

Procedure :

·

Weigh 50 g of sample in a Bakelite screw-cap bottle and

in a similar bottle put the standard nitrating mixture. Place these two bottles

in a thermostat maintained at 20°C until the contents have attained an

equilibrium temperature,

·

Transfer 50 ml of the standard nitrating-acid to the

insulated vessel and insert the motorised stirrer. Just wait for about 3-5

minutes and then start the motorized stirrer. After exactly 1 minute record the

initial temperature,

·

Stop the motor. Insert the sample into the reaction

vessel and start the stirrer. Now, start taking readings of the rise in

temperature after each interval 1, 2, 3 and 5 minutes respectively, and

·

Plot a ‘calibration curve’ between the observed

temperature-rise in a 3 minute interval Vs

percent benzene present in cyclohexane. Run pure cyclohexane and standards

containing 0.5-5.0 percent benzene by weight.

Related Topics