Chapter: Pharmaceutical Drug Analysis: Thermoanalytical Analysis

Thermogravimetric Analysis (TGA)

THERMOGRAVIMETRIC ANALYSIS (TGA)

1. THEORY

A large number of chemical substances invariably

decompose upon heating, and this idea of heating a sample to observe weight

changes is the underlying principle of thermogravimetric analysis (TGA).

However, TGA may be sub-divided into two

heads, namely :

(a) Static (or

Isothermal) Thermogravimetric Analysis, and

(b) Dynamic

Thermogravimetric Analysis.

1.1. Static Thermogravimetric Analysis

In this particular instance the sample under analysis is

maintained at a constant temperature for a period of time during which any

changes in weight are observed carefully.

1.2. Dynamic Thermogravimetric Analysis

In dynamic thermogravimetric analysis a sample is

subjected to conditions of predetermined, carefully controlled continuous

increase in temperature that is invariably found to be linear with time.

2. INSTRUMENTATION

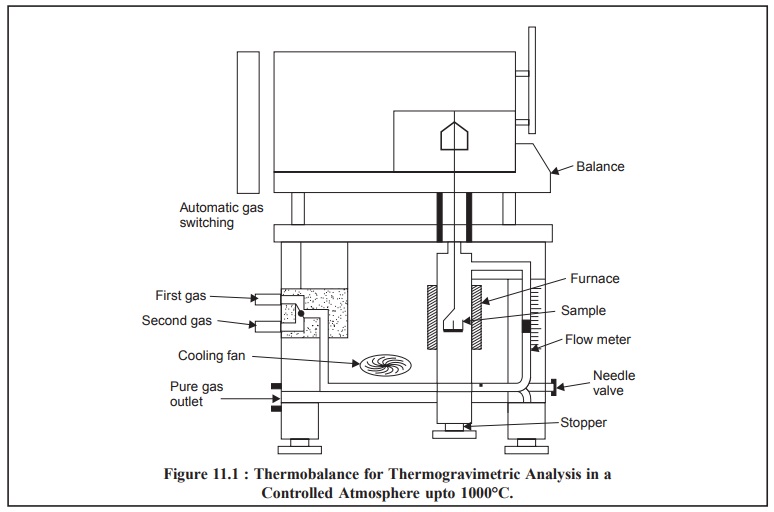

The essential requirements for an instrument (Figure

11.1) meant for thermogravimetric analysis are, namely :

(a) A

high-precision balance,

(b) A furnace

adequately programmed for a linear rise of temperature with time, and

(a)

A sensitive recorder.

2.1. Balances

They are usually of two

types :

(a) Null-point Type : It makes use of an

appropriate sensing-element which aptly detects any slightest deviation of the

balance beam and provides the application of a restoring force, directly

propor-tional to the change in weight, thereby returning the beam to its

original null-point. The restoring-force is subsequently recorded either

directly or with the aid of a transducer.

(b) Deflection Type : It is essentially

based on either a conventional analytical balance consisting of helical spring,

cantilever beam and strain gauze or a torsion analytical balance involving the

conversion of deviations directly into a record of the weight change.

2.2. Furnace

The furnace must be designed in such a fashion so as to

incorporate an appropriate smooth input thereby maintaining either a fixed

temperature or a predetermined linear-heating programme (e.g., 10°C-600°C per hour).

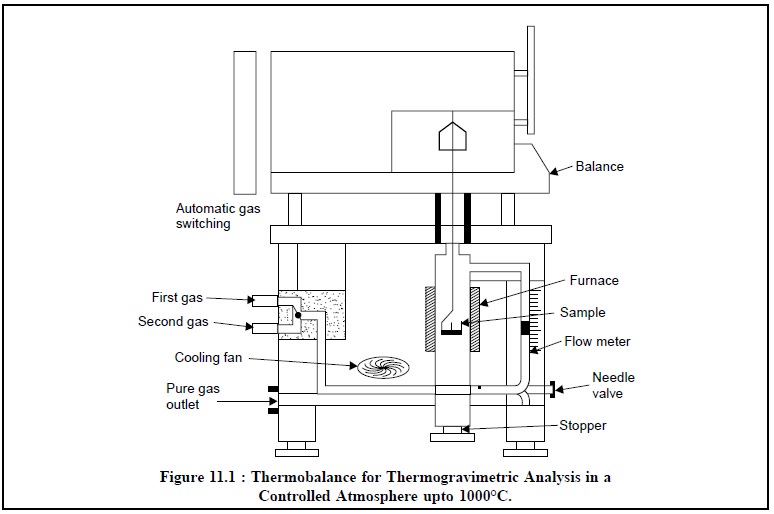

The temperature control of the furnace is satisfactorily

achieved via a thermocouple mounted very close to the furnace-winding. The

maximum operational temperature may be obtained by using different

thermocouples as indicated below :

2.3. Recorder

The recording device must be such so as to :

(i) record both

temperature and weight continuously, and

(ii) make a

definite periodic record of the time.

3. METHODOLOGY

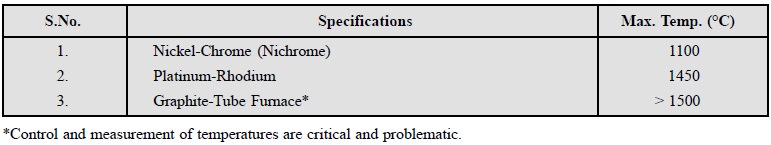

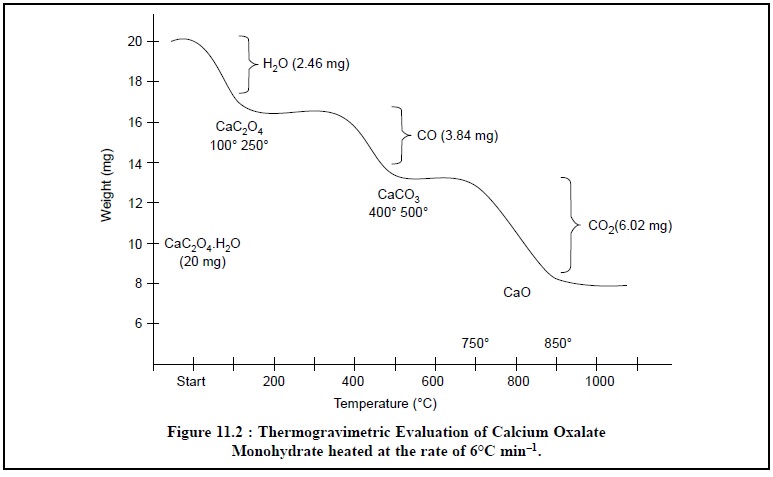

The ‘thermogram’

for calcium oxalate monohydrate (CaC2O4.H2O)

is presented in Figure 11.2. The successive plateaus correspond to the

anhydrous oxalate (100-250°C), calcium carbonate (400-500°C), and finally

calcium oxide (700-850°C). In other words, these plateaus on the decomposition

curve designate two vital aspects,

namely :

(a) clear

indication of constant weight, and

(b) stable

phases within a specified temperature interval. The chemical reactions involved

may be summarized as follows :

3.1. Interpretation of Thermogram

In the thermogram

(Figure 11.2), which

vividly illustrates the

thermogravimetric evaluation of CaC2O4.H2O,

it is ensured that the weight of this product decreases in several stages,

namely :

Stage 1 : The water of hydration (or

crystallization) from calcium oxalate monohydrate is lost which corresponds to 2.46 mg (12.3%) equivalent

to 1 mole of H2O in the temperature range 100-250°C.

Actually, the 12.3% weight loss that took place between

100-250°C should correspond to 12.3% of the original formula weight for CaCO3

H2O (FW = 146). Hence, the product being lost has a formula weight

of 0.123 × 146 = 17.958 ( ~ 18.0), and it corresponds to H2O.

Stage 2 : One mole of carbon monoxide is

evolved subsequently from calcium oxalate, corresponding to 3.84 mg (19.2%) in the temperature range 400-500°C.

The 19.2% weight loss that occurred between 400-500°C

should correspond to 19.2% of the original formula weight of 146. Therefore,

the product being given out has a formula weight of 1.92 × 146 = 28.0, that

corresponds to CO.

Stage 3 : Finally, a mole of CO2 is evolved from calcium carbonate that

corresponds to 6.02 mg (3.01%) in

the temperature range 700-850°C.

The weight loss amounting to 3.01% which took place in

the range 700-850°C must, in fact, corresponds to 3.01% of the original formula

weight of 146. Therefore, the product being evolved has a formula weight of

0.301 × 146 = 43.946 ( ~ 44), and it corresponds to CO2.

![]()

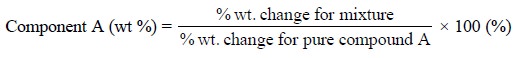

It is quite evident that in a multicomponent system

wherein more than one component exhibits weight variations and that too at

different temperature regions, the composition of the original compound may be

estimated as depicted in Figure 11.2.

In a situation whereby an inert material is present along

with a pure substance, from the generated thermogram the composition of the

mixture may be derived from the percentage weight variation which takes place

relative to the percentage weight variation observed with the pure compound

(A), by employing the following expression :

4. APPLICATIONS

The most broadly based application of the

thermogravimetric analysis (TGA) has been visualized and exploited in the

investigation of analytical methods, such as :

(i) Determining

appropriate forms for many elements,

(ii) Screening

and testing of substances which may be used as potential analytical standards

(primary standard), and

(iii) Direct

application of the technique in analytical assays.

A few typical applications of TGA are, namely :

(a) Plateaus

for hydrates are sometimes based on the initial water content (i.e., water of crystalliza-tion). It has

been observed that in humidified air at low heating rates, hydrates usually

give rise to good plateaus.

Example : Dehydration of sodium

tungstate 28-hydrate [Na2WO4.28 H2O (5 : 12)]

Experimental parameters* :

A. Humidified air, 300°C/hour,

B. Humidified air, 150°C/hour,

C. Humidified air 10°C/hour,

D. Room air, 10°C/hour,

Sample weight : 0.5000 g ;

n = Moles water per 5Na2O,

12 WO3

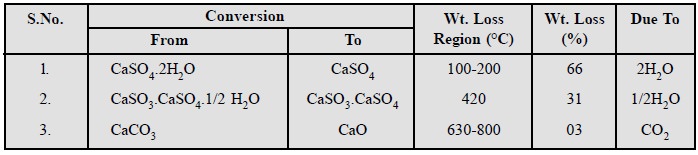

(b) Analysis of

flue-gas scrubber system in environmental analysis.

The flue-gas emitted from a coal-fired-power-plant is subjected

to scrubbing by the aid of wet limestone to get rid of sulphur dioxide (SO2)

as completely as possible. TGA helps in monitoring the system by carrying out

the analysis of the products resulting from the scrubbing process, that mainly

consist of (i) CaCO3 ; (ii) CaSO3 . CaSO3

. 1/4 H2O, and (iii) CaSO4

. 2H2O.

The thermogram obtained from TGA provides the following valuable informations which suggests the decomposition occurring at three distinct stages thereby causing the loss due to two moles of water, half-a-mole of water and one mole of CO2.

(c) The stepwise degradation

of organic polymers has received adequate attention which has broadened the

in-depth knowledge of polymer chemistry. In this specific instance the sample is

either heated under vacuum or in an inert atmosphere (of N2).

(d) The thermogravimetric data

may be employed to evaluate the kinetic parameters of weight varia-tions in

reactions.

Related Topics