Chapter: Mechanical : Gas Dynamics and Jet Propulsion : Jet Propulsion

The Turbofan Engine

The

Turbofan Engine

The

turboprop is limited to mach number of about 0.7 because of the sharp decrease

in propeller efficiency encountered above that mach number. However, the

turboprop concept of increasing mass

flow rate without

producing an excessive increment in exhaust velocity is valid

at any mach number and the use of a ducted fan combined with a jet turbine provides more economical operation at

mach numbers close to unity than does the simple jet turbine. If a duct or

shroud is placed around a jet engine and air is pumped through the annular

passage by means of one or more sets of compressor blades, the resulting engine

is called a turbofan, and is capable of producing (under proper conditions)

somewhat better thrust specific fuel consumption characteristics than the

turbojet itself. Basically, the air passing through the fan bypasses the

combustion process but has energy added to it by the compressor fan, so that a

sizable mass flow can be shunted through the fan. The air which bypasses the

combustion process leaves the engine with a lower amount of internal energy and

a lower exhaust speed than the jet exhaust. Yet, the thrust is not decreased

since the turbofan can pump more air per unit time than a conventional jet at

subsonic speeds. Accordingly, the average exhaust velocity of the turbofan

(averaging the turbine flow and the bypass flow) can be made smaller at a given

flight speed than that of a comparable turbojet and greater efficiency can be

obtained. In turbofan engine the fan cannot be designed for all compressor

ratios which is efficient at all mach numbers, thus, the turbofan is efficient

over a rather limited range of speeds. Within this speed range, however, its

improved cruise economy makes it a desirable unit for jet transport aircraft.

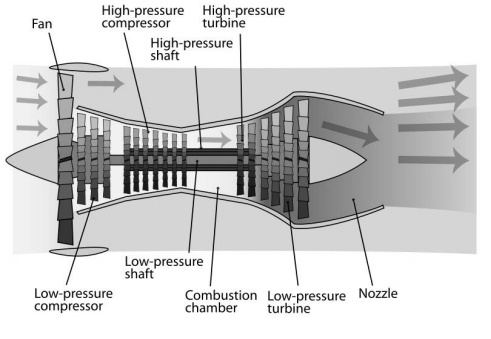

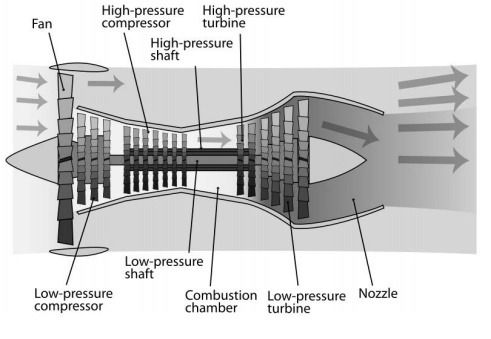

The turbofan engine has

a duct enclosed fan mounted at the front or rear of the engine and driven

either mechanically geared down or at the same speed as the compressor, or by

an independent turbine located to the rear of the compressor drive turbine

(Ref. Figure 7). There are two methods of handling the fan air. Either the fan

can exit separately from the primary engine air, or it can be ducted back to

mix with the primary engine’s air at the rear. If the fan air is ducted to the

rear, the total fan pressure must be higher than the static pressure in the

primary engine’s exhaust, or air will not flow. Similarly, the static fan

discharge pressure must be less than the total pressure the primary engine’s

exhaust, or the turbine will not be able to extract the energy required to

drive the compressor and fan. By closing down the area of flow of the fan duct,

the static pressure can be reduced and the dynamic pressure is increased.

The efficiency of the

fan engine is increased over that of the pure jet by converting more of the

fuel energy into pressure energy rather than the kinetic energy of a high

velocity exhaust gas stream. The fan produces additional force or thrust

without increasing fuel flow. As in the turboprop primary engine exhaust gas

velocities and pressures are low because of the extra turbine stages needed to

drive the fan, and as a result this makes the turbofan engine much quieter. One

fundamental difference between the turbofan and the turboprop engine is that

the air flow through the fan is controlled by design so that the air velocity

relative to the fan blades is unaffected by the aircraft’s speed. This

eliminates the loss in operational efficiency at high air speeds which limits

the maximum air speed of propeller driven aircraft.

Fan engines show a

definite superiority over the pure jet engines at speeds below Mach 1. The

increased frontal area of the fan presents a problem for high- speed aircraft

which, of course require small frontal areas. At high speeds air can be offset

at least partially by burning fuel in the fan discharge air. This would expand

the gas, and in order to keep the fan discharge air at the same pressure, the

area of the fan jet nozzle is increased. This action results in an increase in

gross thrust due to an increase in pressure times an area (PA), and an increase

in gross thrust specific fuel consumption.

Nozzle and diffuser

efficiencies

In ideal case, flow

through nozzle and diffuser is isentropic. But in actual case, friction exists

and affects in following ways:

i) Reduces the enthalpy drop reduces the

final velocity of steam iii) Increases the final dryness fraction iv) Increases

specific volume of the fluid v) Decreases the mass flow rate

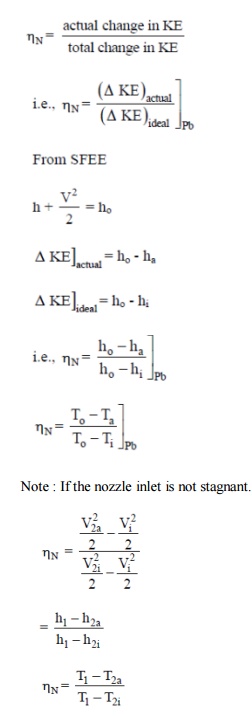

Nozzle performance

The isentropic operating conditions are very easy to

determine. Frictional losses in the nozzle can be accounted by several methods.

(1)

Direct information on the entropy change could be given although this is

usually not available.

(2)

Some times equivalents information is provided in the form of stagnation

pressure ratio. Normally nozzle performance is indicated by efficiency

parameter defined as

Related Topics