Chapter: Mechanical : Gas Dynamics and Jet Propulsion : Jet Propulsion

Pulse Jet Engine

Pulse Jet Engine

The pulse jet engine is an intermittent, compressor

less aerodynamic power plant, with few or none of the mechanical features of

conventional aviation power plants. In its simplest form, the operation of the

pulse jet depends only on the properties of atmospheric air, a fuel, a shaped

tube and some type of flow-check valve, and not on the interposition of

pistons, impellers, blades or other mechanical part whose geometry and motion

are controllable. The pulse jet differs from other types of air breathing

engines, in that the air flow through it is intermittent. It can produce static

thrust.

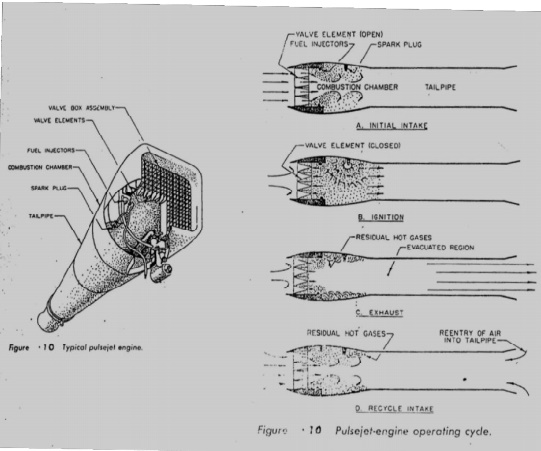

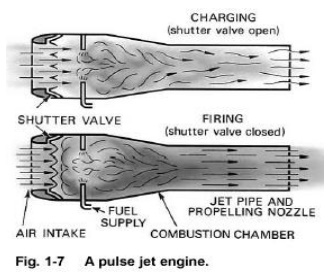

Operations:

During starting compressed air is forced into the

inlet which opens the spring loaded flapper valves. In practice this may done

by blowing compressed air though the valve box or by the motion of the engine

through the air. The air that enters the engine passes by the fuel injector and

is mixed with the fuel(Fig. A)

When the fuel-air mixture reaches the proper

proportion to burn, it is ignited by a spark plug. The burning takes place with

explosive force, thus causing a very rapid rise in pressure, the increase in

pressure forces the flapper valves shut and propels the charge of burned gases

out of the tail pipe, as in B of the figure.

The momentum of the gases leaving the

tailpipe causes the air to continue t flow out even after the pressure within

the engine has reached atmospheric pressure. The pressure within the engine is

therefore evacuated to below atmosphere, part C in figure.

After the pressure has

reached its lowest point, atmospheric pressure (and the ram pressure if the

engine is in flight) forces air into the engine through the flapper valves. At

the same time, air will also be drawn in through tailpipe, since the pressure

within the tailpipe is low and has nothing to prevent the entry of air, At this

point, part D in figure, the engine is ready to begin another cycle. The

fequency of cycles depends upon the duct shape and working temperature in V-1

rocket it was about 40 c/s which corresponds to about 2400 rpm of a two stroke

reciprocating engine.

Once the engine

operation has become established, the spark plug is no longer necessary. The

reignition between each cycle is accomplished when the fresh charge of fuel and

air is ignited by some residual flame which is left over from the preceding

cycle. The air flow which reenters the tailpipe is important from both the

engine operation and thrust stadpoints. Experiments have shown that the amount

of air which flows into the tailpipe can be several times as much as that which

flows into the inlet. This mass flow of air increases the thrust of the engine

by providing additional mass for the explosion pressure to work on. It also

increases the pressure within the engine at the beginning of each explosion

cycle, resulting in a more efficient burning process. Reentry of air into the

tailpipe is made more difficult as the airspeed surrounding the engine

increases. The thrust of the engine, therefore, tends to decrease with speed.

As the speed increases, the amount of reentering air flow decreases to the

point where the internal pressure is eventually too low to support combustion

and the engine will no longer operate.

Characteristics :

The chief advantages of the pulse jet are its

simplicity, light weight, low cost and good zero speed thrust characteristic.

Its particular disadvantages are its 650-800 km/h. operating speed limit,

rather limited altitude range and somewhat unpredictable valve life.

One interesting and sometimes objectionable, feature

of the pulse jet engine is the sound it makes when in operation. The sound is a

series of loud reports caused by the firing of the individual charges of fuel

and air in the combustion chamber. The frequency of the reports depends upon

the length of the engine form the inlet valves to the end of the tailpipe and

upon the temperature of the gases within the engine. The resulting sound is a

continuous, loud, and vibratory note that can usually be heard for several

kilometers.

The pulse jet has low

thermal efficiency. In early designs the efficiency obtained was about 2 to 3%

with a total flight life of 30 to 60 minutes. The maximum operating speed is

seriously limited by tow factors: (i) It is possible to design a good diffuser

at high speeds. (ii) The fiepper valves, the only mechanical part in the pulse

jet, also have certain natural frequency and if resonance with the cycle

frequency occurs then the valve may remain open and no compression will take

place. Also, as the speed increases it is difficult for air to flow back. This

reduces total compression pressure as well as the mass flow of air which

results in inefficient combustion and lower thrust. The reduction in thrust and

efficiency is quite sharp as the speed increases.

Advantages :

Ø This

is very simple device only next to ramjet and is light in weight. It requires

very small and occasional maintenance.

Unlike ramjet, it has

static thrust because of the compressed air starting, thusit does not need a

device for initial propulsion. The static thrust is even more than the cruise

thrust.

Ø It

can run on an almost any type of liquid fuel without much effect on the

performance. It can also operate on gaseous fuel with little modifications.

Ø Pulse

jet is relatively cheap.

Disadvantages :

Ø 1.The

biggest disadvantage is very short life of flapper valve and high rates of fuel

consumption. The SFC is as high as that of ramjet.

Ø The

speed of the pulse jet is limited within a very narrow range of about 650-800

km/h because of the limitations in the aerodynamic design of an efficient

diffuser suitable for a wide range.

Ø The

high degree of vibrations due to intermittent nature of the cycle and the

buzzing noise has made it suitable for pilotless crafts only.

Ø It

has lower propulsive efficiency that turbojet engine.

Ø The

operational range of the pulse jet is limited in altitude range.

Applications:

Ø German

V-1 buzz bomb,

Ø

American Helicopter company’s Jet Jeep

Helicopter,

Ø

Auxiliary power plant for sail planes.

Related Topics