Chapter: Civil : Prefabricated Structures : Introduction

Systems of prefabrication

Systems

of prefabrication:

System is referred to a

particular method of construction of buildings using the prefabricated

components which are inter related in functions and are produced to a set of

instructions. With certain constraints, several plans are possible, using the

same set of components, the degree of flexibility varies from system to system.

However in all the systems there is a certin order and discipline. The system

of prefabricated construction depends oon the extend of the use of prefab

components, their characteristics to be considered in devising a system:

i.

Intensified usage of spaces

ii.

Straight and simple walling scheme

iii.

Limited sizes and numbers of components

iv.

Limited opening in bearing walls

v.

Regulated locations of partitions

vi.

Standardized service and stair units

vii.

Limited sizes of doors and windows with regulated

positions

viii.

Stuctural clarity and efficiency

ix.

Suitability for adoption in low rise and high rise

blocks

x.

Ease of manufacturing storing and transporting

xi.

Speed and ease of errection

xii.

Simple jointing system

a) Based on

Disuniting of member

b) b) Based

on the construction

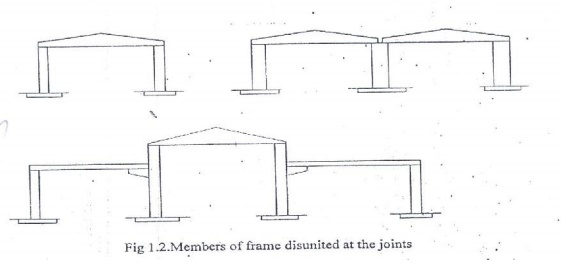

Based on Disuniting of member:

1. System

consisting of linear member disunited at joints

2. System

for prefabricates of entire rigid frame

3. System

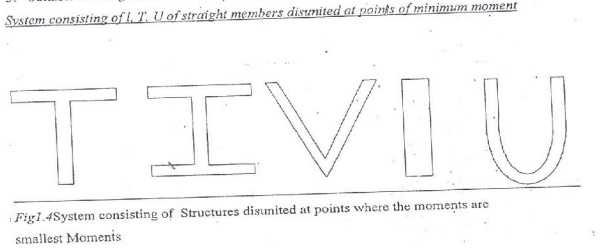

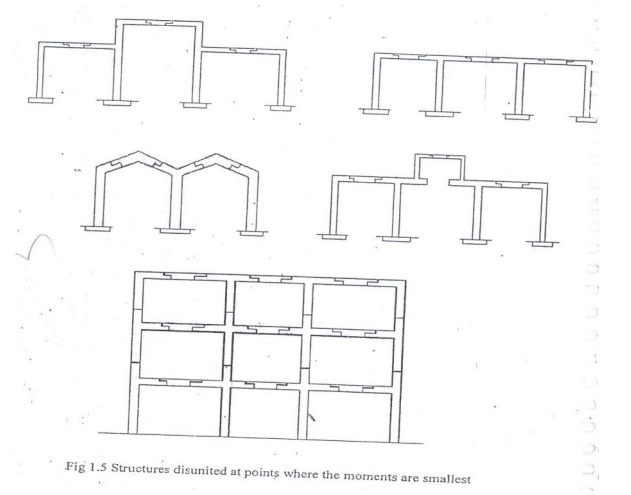

consisting of I,T,U of straight members disunited at points of minimum moment.

4. Two

hinged and three hinged arches

System consisting of linear member disunited at

joints:

Advantage:

Disuniting at joints gives linear

member. This means that a great advantage and facilitates from the view point

manufacture and assembly.

Disadvantage:

1. Joints

are at corners i.e. at points of maximum moment values, so forming the joint is

difficult.

2. Joints

must be over dimensioned to cope with insitu concreting. And one alternate

solution to replace moment resistant joints by hinged connection.

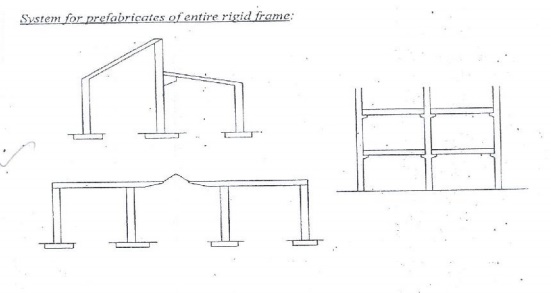

System

for prefabricates of entire rigid frame:

In this system, to reduce the no

of joints and to precast larger numbers I one piece leads to the prefabrication

of entire frame. Production of the frames does not cause any particular trouble

but the hoisting is more difficult and requires careful preparation.

The stress distribution of staright members during hoisting is

in general statistically determinate.

Advantage:

1. It is

ideal for site prefabrication.

2. Small

number of joints so rapid prefabrication work is possible.

3. Suitable

for long walls consisting of great number of uniform frames.

System

consisting of I,T,U of straight members disunited at points of minimum moment:

Another method of disuniting of

structures is by division into different membranes at points where the moments

are thin or smallest. This method is called as lambda method. Using this method

hinge joints are made.

Advantage:

1. Functions

are made at points of minimum moments or at points of contra flexure.

2. Disuniting

the main girder in this manner makes the application of different skylights

possible.

Disadvantage:

1. Hosting

and temperature bracing of L joined asymmetric frame members is particularly

complicated.

2. Temperature

resting of frame member on each other necessaitates the use of canilevers

having half depth and proper forming of this cause difficulty.

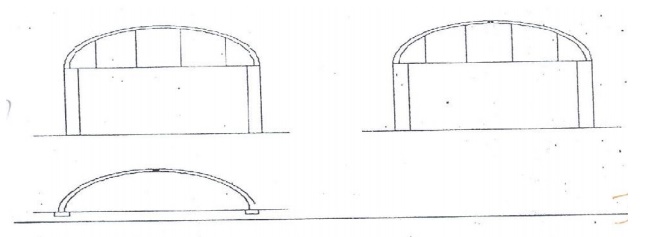

Two hinged and three hinged arches

Arched structures are normally

two hinged and three hinged arches. Arched structures are normally used for

bridging span more than 20-25m. Their production and placing is more difficult

than straight members. Arch can be two hinged and three hinged but they can

also be fixed at footings nd can be constructed with or without tie.

These members are generally

precast and assembled in statistically determinant three hinged variance and

middle hinge is only eliminated after placing is finished. The reinforcing bars

protruding both sides are welded together and the joint between the members is

filled in with insitu concrete.

Arch

structure can be precast in either vertical or horizontal positions. In the

first case, shuttering made of timber or concrete is required having the same

curvature s the arch itself. The prefabrication of larger arches in theh

horizontal position is found to be more economical The construction of arch

trusses can be properly carried out in the horizontal position only.

Related Topics