Chapter: Civil : Prefabricated Structures : Introduction

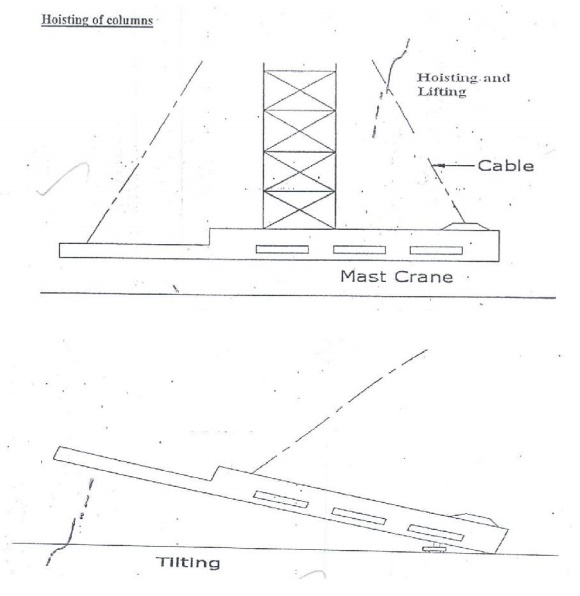

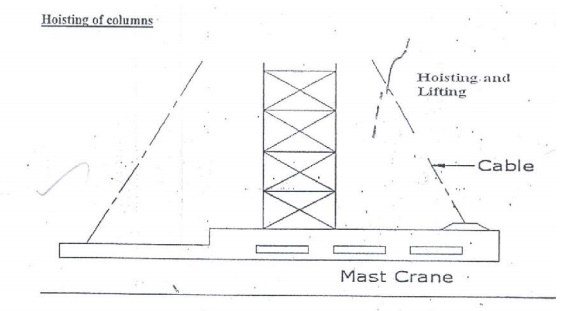

Hosting of Columns

Hosting

of Columns:

The hoisting machine for small

column is less than five tones. First of all pick up gear must be assembled on

to the column and the column is then under pinned.

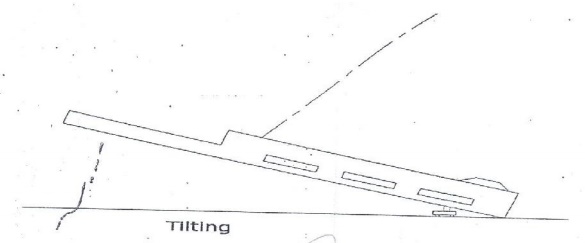

Thereafter the column is lowered

temporarily on to a sheep shoe assembled at the foot and the roller track is

pushed under the shoe. When column is hoisted the pick up points moves

vertically and bottom resting on the roller tracks shifts towards the footing.

When the column is lifted to the required height, the retaining cable is used

to decrease and finally stop the swinging motion of the column.

The

hoisting and fixing up of the beams:

1. Pick up

and hoisting

Beams in general are liftedat two points depending on the

weight and dimmensioons as well as the load bearing capacity of hoisting

machines. The hoisting grider which is heavy to a great can be executed with

hydraulic jacks. The jacks are lowered and the beam is placed to the required

position to the column.

Suspension:

For lifting up of trusse and

large beams of length 25-30m. care is taken to lift the rocker in uniform rate

with two hoisting machines otherwise the beams would be subjected to distortion

during the lifting leading to cracks.

Methods of prefabrication:

Site prefabrication- for large prefabricates

Plant prefabrication- large scale production

Site prefabrication:

1. The RC

members are produced t the site in the open air chiefly in the open air or in

the temporary sheds

2. The

difficulties in construction in general are felt in this mechanization can

case.

3. Mechanization

can not be of such high degree as site PF is done for smaller duration of time.

4. When the

pre fabricates are of large size it is difficult to transport the pre

fabricates to the site.

5. In

comparison with plant prefabrication transportation of the members are not

needed. As large members are not transported the design and weight of the

prefabricates are not limited.

![]() Plant prefabrication

Plant prefabrication

1. The

members produced are to be transported t the place of costruction this accounts

for about 10-15% of the cost of production and assembling.

2. Certain

restriction is made in the dimension of prefabrication leading to restrainst in

the design and development of prefabrication.

3. Prefabrication

is appropriate for mass production for manufacture of standaridized members.

4. Needs costy materials for batching and production.

5. This

method is most suited in the case of small prefabricates which are to be

prefabricated in very large number.

Plantt prefabrication is done under permanent plant or

factories. It is done under the covered roof so the effect of weather does not

affect the work. So the quality and strength of the members can be improved

considerably. Plant prefabrication reduces the cost of prefabrication if the

number of prefabricate needed is more.

Dimensions

of prefabricate:

There are

3 commonly known dimension for the prefabricates.

1. The

design of the errectio dimension governing the dimensional coordination of the

prefabricates.

2. Theoretical

dimension

3. The

actual dimension of the element when delivered the design dimension should be a

multiple of abasic module size m or of a module lmp.

Production of prefabricates:

Production techniques involved are

1. Stand

method

2. Conveyor

method or line method

3. Aggregate

method

Stand Method:

In this method, the

prefabrication mature where they are moulded while the production teams moves

to successive stands. The bed on whih prefabricates are cast may be fixed or

movable. Tilting forms are often uused and in tthis method steam curing is

generally done.

Conveyor belt method:

The whole

production is split up in to series operations carried out at separate

successive and permanent points served by specialized teams. The movement of

the mould or prefabricate one point to other vary by means of conveyor belt

trolleys.

The rigid steel forms are

assembled at station 1 where they are mould oil to reduce the adhesion of

concrete.The conveyor moves fron 1 to 2 where prestressing wires are fixed

& in the next station anchoring of the wires is carried out. The prepared

mould is then carried to the station 1ie casting station.After casting ,it is

shifted to the vibrating table & finally stacked @ station 5 for setting.

After that,it is passed through

tunnel autoclave for curing.After steam curing move too station 7 for

demoulding & is finally stacked @ 8.

Aggregate method:

In the aggregate method,aggregate

describes large complex permanently installed machines & mechanical

appliances which carry out most of the separate operations involved in the

casting of the concrete composition.The stand is operated by a permanent team

& the only move the prefabricate makes is to the maturing point.

Aggregate method is used in the

production of multi duct hollow floor pannel in Poland.At production point the

reinforcement is fixed in the form & remote controlled

aggregate(machine)inserts the duct formers,cast& vibrates the

concrete,floats @ the top of the floor.The prepared prefabricate then move to

the autoclave chamber in which hardening of concreteis accelerate.In many

factories combined technology are employed when complex prefabricate are

required.

Advantages:

1.The stand technique is the most

flexible one.It is used in varying degrees of mechanization,in all kinds of

prefabricate factories.

2.It is

simple & less capital is required.It can be used for field prefabricate

also.

3.Aggregate

method is used for large scale productionin which case number of machineries is

required.

Related Topics