Chapter: Electrical machines : DC Motor

SwinburneŌĆÖs Test

SwinburneŌĆÖs

Test

For a d.c shunt motor change of speed from no

load to full load is quite small. Therefore, mechanical loss can be assumed to

remain same from no load to full load. Also if field current is held constant

during loading, the core loss too can be assumed to remain same.

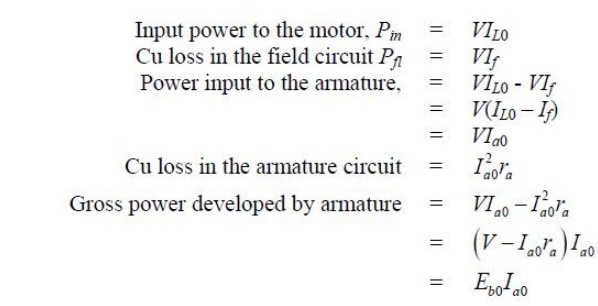

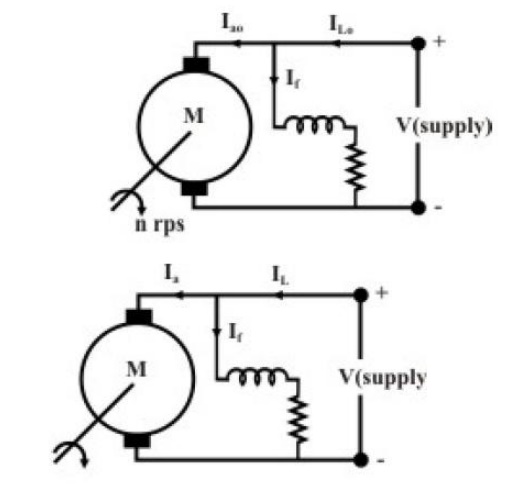

In this test, the motor is run at rated speed

under no load condition at rated

voltage. The current drawn from the supply IL0

and the field current If

are recorded (figure 40.3). Now we note that:

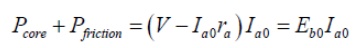

Since the

motor is operating under no load condition, net mechanical output power is

zero. Hence the gross power developed by the armature must supply the core loss

and friction & windage losses of the motor. Therefore,

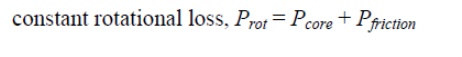

Since,

both Pcore and Pfriction for a shunt motor

remains practically constant from no load to full load, the sum of these losses

is called constant rotational loss i.e.,

In the

Swinburne's test, the constant rotational loss comprising of core and friction

loss is estimated from the above equation.

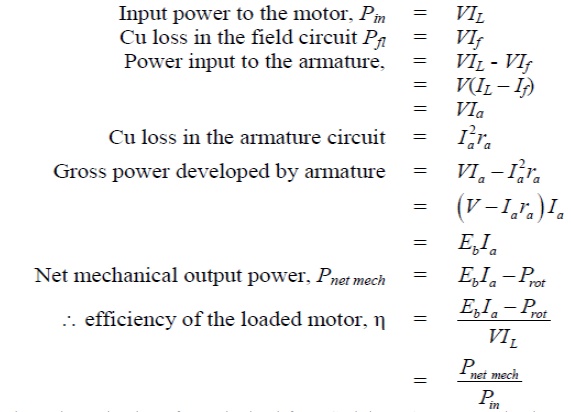

After

knowing the value of Prot

from the Swinburne's test, we can fairly estimate the efficiency of the motor

at any loading condition. Let the motor be loaded such that new current drawn

from the supply is IL and

the new armature current is Ia

as shown in figure 40.4. To estimate the efficiency of the loaded motor we

proceed as follows:

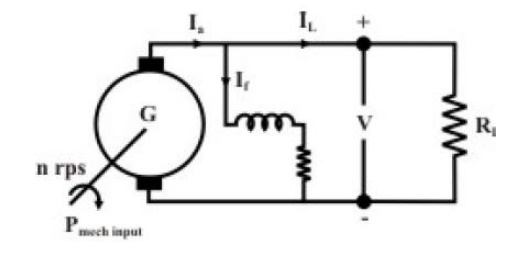

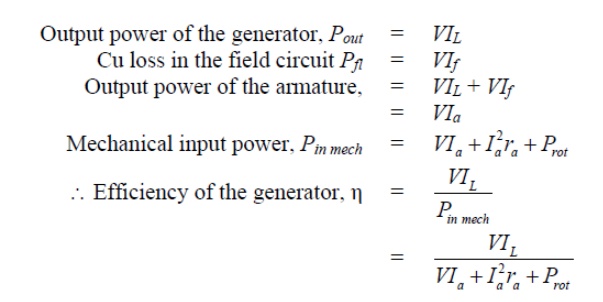

The

estimated value of Prot

obtained from SwinburneŌĆÖs test can also be used to estimate the efficiency of

the shunt machine operating as a generator. In figure 40.5 is shown to deliver

a load current IL to a

load resistor RL. In this

case output power being known, it is easier to add the losses to estimate the

input mechanical power.

The

biggest advantage of Swinburne's test is that the shunt machine is to be run as

motor under no load condition

requiring little power to be drawn from the supply; based on the no load

reading, efficiency can be predicted for any load current. However, this test

is not sufficient if we want to know more about its performance (effect of

armature reaction, temperature rise, commutation etc.) when it is actually

loaded. Obviously the solution is to load the machine by connecting mechanical

load directly on the shaft for motor or by connecting loading rheostat across

the terminals for generator operation. This although sounds simple but

difficult to implement in the laboratory for high rating machines (say above 20

kW), Thus the laboratory must have proper supply to deliver such a large power

corresponding to the rating of the machine. Secondly, one should have loads to

absorb this power.

Related Topics