Chapter: Electrical machines : DC Motor

Starting of DC Motors

Starting

of DC Motors

The speed

of the machine has to be increased from zero and brought to the operating

speed. This is called starting of the motor. The operating speed itself should

be varied as per the requirements of the load. This is called speed control.

Finally, the running machine has to be brought to rest, by decelerating the

same. This is called braking.

At the

instant of starting, rotor speed n = 0, hence starting armature current is

Ist=V/ra. Since, armature resistance is quite small, starting current may be

quite high (many times larger than the rated current). A large machine,

characterized by large rotor inertia (J), will pick up speed rather slowly.

Thus the level of high starting current may be maintained for quite some time

so as to cause serious damage to the brush/commutator and to the armature

winding. Also the source should be capable of supplying this burst of large

current. The other loads already connected to the same source, would experience

a dip in the terminal voltage, every time a D.C motor is attempted to start

with full voltage. This dip in supply voltage is caused due to sudden rise in

voltage drop in the source's internal resistance. The duration for which this

drop in voltage will persist once again depends on inertia of the motor. Hence,

for small D.C motors extra precaution may not be necessary during starting as

large starting current will very quickly die down because of fast rise in the

back emf. However, for large motor, a starter is to be used during starting.

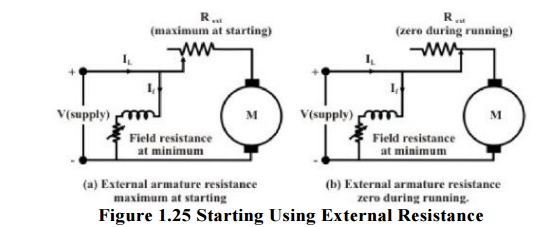

A simple

starter to limit the starting current, a suitable external resistance R is

connected in series, as shown in the figure, with the armature so that

Ist=V/(R+ra) At the time of starting, to have sufficient starting torque, field

current is maximized by keeping external field resistance Rf to zero value. As

the motor picks up speed, the value of R is gradually decreased to zero so that

during running no external resistance remains in the armature circuit. But each

time one has to restart the motor, the external armature resistance must be set

to maximum value by moving the jockey manually. Now if the supply goes off,

motor will come to a stop. All on a sudden, let us imagine, supply is restored.

This is then nothing but full voltage starting. In other words, one should be

constantly alert to set the resistance to maximum value whenever the motor

comes to a stop. This is one major limitation of a simple rheostatic starter.

Related Topics