Chapter: Civil Surveying : Fundamentals and Chain Surveying

Surveying Corrections for Baseline

Corrections.

for Baseline

It is necessary to

apply the following corrections to the field measurements of base line order

its true length:

1.Correction for

absolute length Adverti 2.Correction for temperature

3.Correction of tension

or pull

4.Correction for Sag

5.Correction for slope

of vertica

It may be noted that

each section of a base line is separately corrected.

1. Baseline Correction

for Absolute Length:

It is given by the

formula

Where CA = Correction

for absolute length L = measured length

of base l = Nominal length of measuring

unit

C = Correction to measuring unit

Sign of CA is the same

as that of C

Nominal length: The

designated length i.e 50 tape, 100 tape (30 m tape)

Absolute length: The

actual length under specified conditions

2. Correction for

Temperature:

It is given by the

formula

Ct = Inf (Tm-To) --

> (B)

Where

Ct = Correction for

temp

= co-efficient of thermal

Tm = Mean Temperature

during

To = Temp at which the

measuring is standardized

Steel = 0.0000099-0.000012/c

Steel = 0.0000055 - 0.0000070/ F

The sign of 'Ct' is

plus or minus according to as 'Tm' is greater or less then 'to'

1. Correction

for Pull or Tension

Cp

= (Pm - Po)/AE . L -- > (c)

Where

CP

= Correction for pull

Pm

= Pull applied during measurement

Po

= Pull at which the measurement unit (tape) is standardized

L

= length measured

A

= Cross-Sectional area of measuring unit

E

= Modulus of elasticity of measuring unit

E

steel = 21 x 105 kg / cm2

E

steel = 30 x 106 /bs/in2

The

sing of this correction is always plus (T) as the effect of pull is to increase

the length of the tape and consequently to decrease the measured length of the

base.

4.

Correction for Sag:

Correction

for sag is the deference in length between the are and its chord i.e b/t the

curved length of the laps and the distance between the supports. It's us

required only when the tape is

suspended

during measurement. Since the effect of sag is to make the measured length too

large, it is always subtractive.

It

is given by the formula.

Cs=

L1(WL12)/24Pm2 -- > (D)

Where

Cs = Correction for Sag

L1

= Distance b/t supports.

W

= wt of tape per unit length

Pm

= applied pull

W

= wt of tape b/t supports.

If

there are 'n' equal space per tape length,

L

= nL1

Sag

correction per tape length is

Cs

= nL1(WL1)2/24Pm2 = L(WL1)2/24Pm2

= L(WL)2/24nPm2

Total sag correction to

measures length

Cs=N x Cs/ + Cs//

Where N = no of whole

tape length

Cs/ = Sag correction

per tape length.

Cs// = Sag correction

for any tape length

Normal tension:

The normal tension of a

tape is a tension which will cause the effects of pull and sag to neutralize

each other. It may be obtained by equating the corrections for pull and sag

Pn = 0.0204W Rt(AE) /

Rt(Pn-Po) -- > (E)

Where Pn = normal

tension

W = wt of tape b/w

supports

Pn is determine by

trial

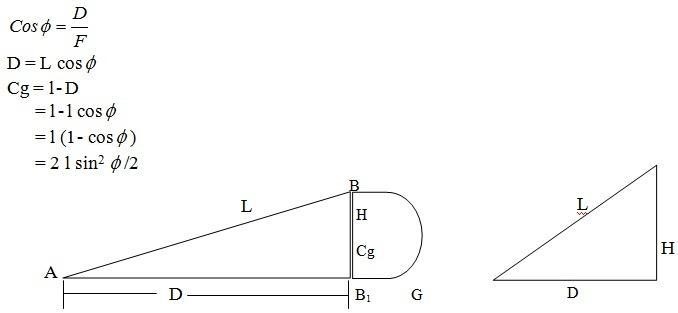

5. Correction for Slope

or Vertical Alignment:

This correction is

required when the points of supports are not exactly at the same level

L1, L2------------

= Successive length of

uniform garages

B1, b2------------ = Difference of elevation b/t the

extremities of each of these grades.

Cg = corr for slope

Cg = B1C1 = AC1 - AB1 =

l -D

Cg =l-Rt(l2-h2) -- >

Exact

This correction is

always negative for measured length.

Related Topics