Chapter: Pharmaceutical Drug Analysis: Gravimetric Analysis

Substances Assayed Gravimetrically

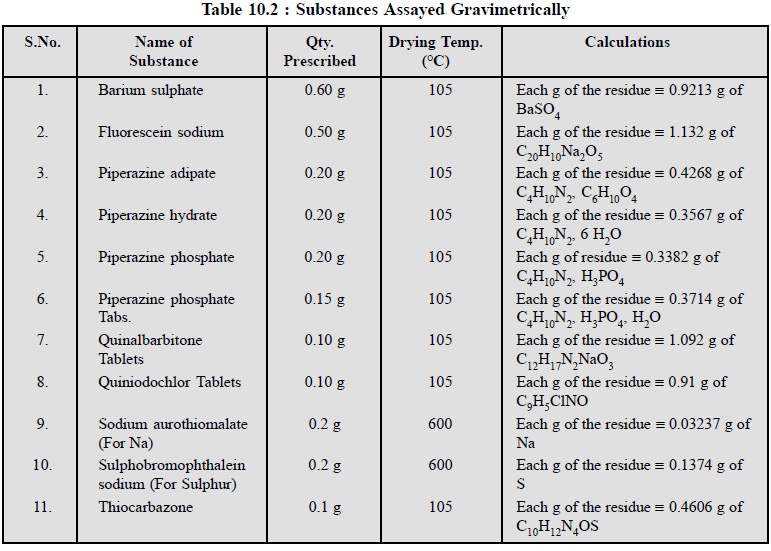

SUBSTANCES ASSAYED GRAVIMETRICALLY

A good number of pharmaceutical substances may be

determined gravimetrically by obtaining their respective difficultly soluble

salts as precipitates, weighing to a constant weight and finding the percentage

purity of the substance in question.

A few typical examples are cited below so as to expatiate

the procedure as well as the theoretical aspects.

1. Sodium Chloride

Materials Required : Sodium chloride : 0.25 g ; 5%

w/v silver nitrate in DW (+ 2-3) drops of conc. HNO3 ; dilute nitric

acid (6 N) ; asbestos fibre.

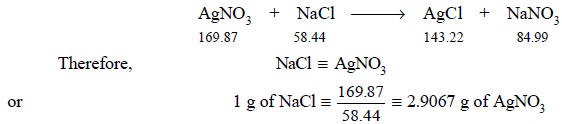

Theory : The following reaction forms

the basis for the calculation of the theoretical amount of silver nitrate solution required as well as

the purity of the given sample of NaCl. Thus, we have :

As 0.2570 g of NaCl has been used (from experimental

data); therefore, the exact amount of AgNO3 required would be :

Hence, the amount of AgNO3 solution required

theoretically would be 0.7470/0.05 = 14.94 ml.

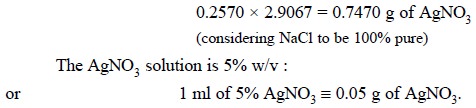

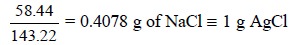

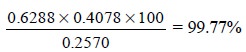

From above, the percentage purity of the given sample of

NaCl may be found as shown below :

The weight of AgCl is found to be 0.6288 g

experimentally, or 0.4078 is the ‘gravimetric factor’.

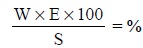

Consequently, the percentage purity of the sample is

determined by the formula :

where, W = Wt. of the product of a chemical reaction with the substance

under determination,

E = Gravimetric Factor, and

S = Wt. of the sample.

By incorporating the data given above, the amount of

sodium chloride present in 100 g of the sample i.e., the percentage purity of NaCl in the given sample may be

calculated as follows :

Procedure : Weigh accurately between 0.20

to 0.30 g of sodium chloride and dissolve in 100 ml of DW. Add to it 1 ml of dilute nitric acid gradually with constant

stirring. Check and confirm that the resulting solution is acidic with the help

of blue litmus paper. Measure out 5.0 ml in excess of the amount of silver

nitrate solution calculated on theoretical basis to precipitate all the

available chlorine as silver chloride. The requisite quantity of silver nitrate

solution must be added in small lots at intervals with constant stirring with a

glass rod. Cover the beaker with a watch-glass and boil the contents very

gently with occasional stirring (to avoid bumping of the liquid and loss of

volume). Stop heating and digest the mixture for 10 minutes so as to

agglomerate the precipitate and enhance settling thereby leaving a clear

supernatant liquid. Add 2 drops of silver nitrate solution to the hot

supernatant liquid in order to confirm whether precipitation is completed. Keep

the beaker away from direct sunlight to allow the precipitate to settle.

Take a properly prepared Gooch crucible, heat to constant

weight and fit it into the suction flask. Decant most of the supernatant liquid

first into the Gooch crucible by applying gentle suction to hasten filtration.

Wash the precipitate on the Gooch crucible at least thrice with 15 ml portions

of 0.01 N nitric acid.

Test the above filtrate to be free of AgNO3.

Finally wash the precipitate twice with 5 ml portion of DW to get rid of most

of the HNO3 previously retained by the precipitate from the former

wash solution. Now, apply vigorous suction to drain out the liquid from the

precipitate to the maximum extent. Dry the crucible to a constant weight

between 110-120°C in an electric oven until two concurrent weighings are

achieved. Thus, the weight of the crucible (tare) must be deducted from the

weight of the crucible plus the precipitate to arrive at the weight of silver

chloride duly obtained from the sample.

Precautions :

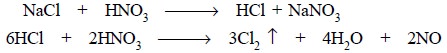

1.

The solution of the substance is usually acidified with

HNO3 to check the precipitation of other substances insoluble in

water but soluble in HNO3 e.g.,

CO32–, O2– and PO43–.

Besides HNO3 also helps to coagulate any colloidal AgCl,

2.

The excess of HNO3 must be avoided to cause

solvolysis of silver halides,

3.

Heating should be affected only after the addition of

AgNO3, otherwise Cl2 may be liberated and lost. Thus, we

have :

4.

The precipitation should preferably be carried out in the

absence of strong light because AgCl undergoes decomposition in sunlight with

loss of Cl2,

5.

Washing of the precipitate (AgCl) with 0.01 N HNO3

is always recommended to prevent loss of AgCl by virtue of its return to

colloidal condition (peptization) and to get rid of the soluble salts, namely :

AgNO and NaNO3, and

6.

AgCl is significantly volatile on ignition, hence it must

always be dried at a comparatively lower temperature.

2. Potassium Alum, KAl(SO4)2, 12H2O

Theory : The percentage of Al in

potassium alum can be determined volumetrically by complexometric titration.

However, gravimetric procedure provides a fairly reliable

and useful alternative method of analysis for

Al which may be accomplished by :

(a)

precipitation from a solution of the aluminium salt by the addition of NH4OH

in the presence of NH4Cl, and

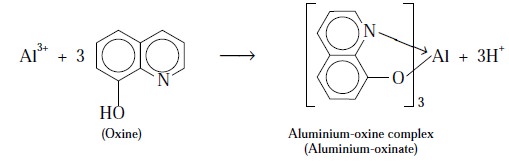

(b)

complexation from a solution of the aluminium salt with 8-hydroxyquinoline

(oxine) either from an ammoniacal solution or from acetic acid-acetate buffer.

In the first method, the following reaction takes place :

Al3+ + 3OH–

→ Al(OH)3 ↓

The gelatinous white precipitate of Al(OH)3 is

duly filtered, washed with dilute NH4NO3 solution,

transformed to the corresponding oxide and finally weighed as Al2O3

.

Disadvantages : There are a number of serious

disadvantages of this method, namely :

(i) excess of

NH4OH may directly affect the solubility of Al(OH)3,

(ii)

coprecipitation of metal hydroxides that are usually soluble in NH4OH,

(iii) heated

oxide (Al2O3) is hygroscopic in nature, and

(iv) hydroxides

may not undergo complete thermal decomposition.

Due to the above short-comings, the second method is

usually preferred which shall be discussed below :

Equation :

The resulting precipitate of aluminium-oxine complex is

crystalline in nature and hence can be filtered conveniently, washed with water

and finally dried at 130-150°C to constant weight.

Disadvantages : There are two disadvantages of the metal-oxine-complex method, namely :

(i)

aluminium-oxinate is prone to adsorb oxine, and

(ii) lack of

selectivity of oxine such that all metals except the alkaline earths (Ba, Mg,

Ca, Sr, Be) and alkali (Li, Na, K, Rb, Cs) should be totally absent.

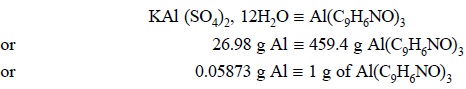

Calculations :

Materials Required : Potassium alum : 0.3 g ; 0.1 N

hydrochloric acid : 1.0 ml ; 8-hydroxyquinoline reagent (or oxine-reagent) (25 ml of a 2% w/v solution of oxine in

2 N acetic acid) ; 2 N ammonium acetate (dissolve 15.0 g of ammonium acetate in

20.0 ml of DW, add 0.3 ml of glacial acetic acid and dilute to 100 ml with DW)

; sintered glass crucible No : 3 or 4.

Procedure : Weigh accurately about 0.3 g

of potassium alum in a 400-ml beaker, dissolve it in 150 ml of DW containing 1.0 ml of 0.1 N HCl and warm the contents of the

beaker to about 60°C. Add the requisite quantity of the oxine reagent and then

add a 2 N solution of ammonium acetate gradually from a pipette till

precipitation just commences. Add a further portion (50 ml) of ammonium acetate

solution with vigorous stirring. Allow the contents of the beaker to stand for

60 minutes with frequent stirring. Filter the precipitate through No : 3 or 4

sintered glass crucible that has been previously dried to a constant weight at

130—150°C. Wash the precipitate throughly with cold DW and dry at 130 to 150°C

to constant weight. Each gram of aluminium oxinate is equivalent to 0.05873 g

of Al.

3. Cognate Assays

A good deal of pharmaceutical substances are officially

assayed gravimetrically as appears in Table 10.2.

Related Topics