Chapter: Mechanical and Electrical : Power Plant Engineering : Steam Power Plants

Steam Power Plants System

STEAM POWER PLANT

Coal needs to be stored at various stages of the

preparation process, and conveyed around the CPP facilities. Coal handling is

part of the larger field of bulk

Material

handling, and is a complex and vital part of the CPP.

FUEL

HANDLING SYSTEM

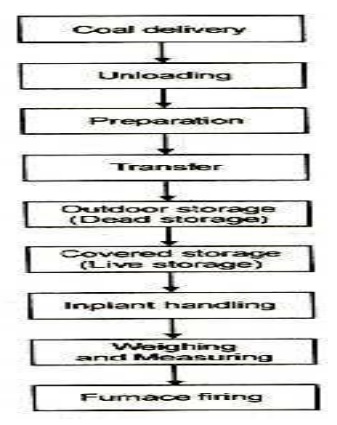

Coal delivery equipment is one of the major

components of plant cost. The various steps involved in coal handling are as

follows:

1. Coal

delivery.

2. Unloading

3. Preparation

4. Transfer

5. Outdoor

storage

6. Covered

storage

7. Implant

handling

8. Weighing

and measuring

9. Feeding

the coal into furnace

i) Coal delivery

The coal from supply points is

delivered by ships or boats to power stations situated near to sea or river

whereas coal is supplied by rail or trucks to the power stations which are

situated away from sea or river. The transportation of coal by trucks is used

if the railway facilities are not available.

ii) Unloading

The type of equipment to be used

for unloading the coal received at the power station depends on how coal is

received at the power station. If coal delivered by trucks, there is no need of

unloading device as the trucks may dump the coal to the outdoor storage. Coal

is easily handled if the lift trucks with scoop are used. In case the coal is

brought by railways wagons, ships or boats, the unloading may be done by car

shakes, rotary car dumpers, cranes, grab buckets and coal accelerators. Rotary

car dumpers although costly are quite efficient for unloading closed wagons.

(iii) Preparation

When the coal delivered is in the

form of big lumps and it is not of proper size, the preparation (sizing) of

coal can be achieved by crushers, breakers, sizers, driers and magnetic

separators.

iv)Transfer

After

preparation coal is transferred to the dead storage by means of the following

systems.

1. Belt

conveyors

2. Screw

conveyors

3. Bucket

elevators

4. Grab

bucket elevators

5. Skip

hoists

6. Flight conveyor

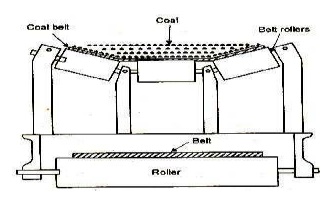

Belt Conveyor

Figure shows a belt conveyor. It

consists of an endless belt moving over a pair of end drums (rollers). At some

distance a supporting roller is provided at the centre. The belt is made up of

rubber or canvas. Belt conveyor is suitable for the transfer of coal over long

distances. It is used in medium and large power plants. The initial cost of

system is not high and power consumption is also low. The inclination at which

coal can be successfully elevated by belt conveyor is about 20 .Average

speed preferred than other types.

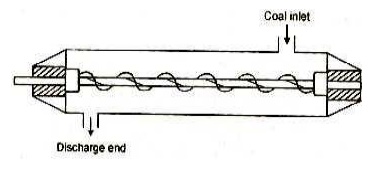

2. Screw Conveyor

It consists of an endless

helicoid screw fitted to a shaft (figure). The screw while rotating in a trough

transfers the coal from feeding end to the discharge end.

This system is suitable, where

coal is to be transferred over shorter distance and space limitations exist.The

initial cost of the consumption is high and there is considerable wear o screw.

Rotation of screw varies between 75-125 r.p.m

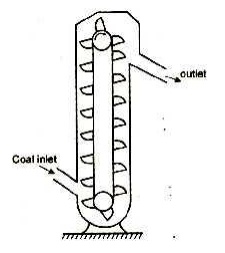

3. Bucket elevator

It consists of buckets fixed to a

chain (figure). The chain moves over two wheels. The coal is carried by the

bucket from bottom and discharged at the top.

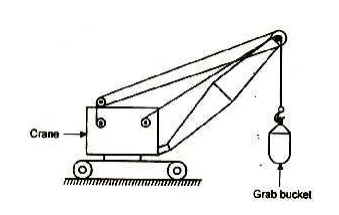

4. Grab bucket elevator

It lifts and transfers coal on a single rail or

track from one point to the other. The coal lifted by grab buckets is

transferred to overhead bunker or storage. This system requires less power for

operation and requires minimum maintenance.

The grab bucket conveyor can be

used with crane or tower as shown in figure . Although the initial cost of this

system is high but operating cost is less.

Storage

of Coal

It is desirable that sufficient quantity of coal

should be stored.Storage of coal gives protection against the interruption of

coal supplies when there is delay in transportation of coal or due to strike in

coal mines. Also when the prices are low, the coal can be purchased and stored

for future use.

The amount of coal to be stored depends on the

availability of space for storage, transportation facilities, the amount of

coal that will whether away and nearness to coal mines of the power station.

Usually coal required for one month operation of power plant is stored in case

of power stations is situated at longer distance from the collieries whereas

coal need for about 15 days is stored in case of power station situated near to

collieries. Storage of coal for longer periods is not advantageous because it

blocks the capital and results in deterioration of the quality of coal.

PULVERIZED COAL STORAGE

Periodically a power plant may

encounter the situation where coal must be stored for sometimes in a bunker,

for instance during a plant shut down. The bunker, fires can occur in dormant

pulverized coal from spontaneous heating within 6 day of loading. This time can

be extended to 13 days when a blanket of CO2 is piped into the top of the

bunker. The perfect sealing of the bunker from air leakage can extend the

storage time as two months or more. The coal in the bunker can be stored as

long as six months by expelling air from above the coal with the use of CO2 and

then blanketing of all sources of air. A control system used for storing the

pulverized fuel in bunker is shown in figure.

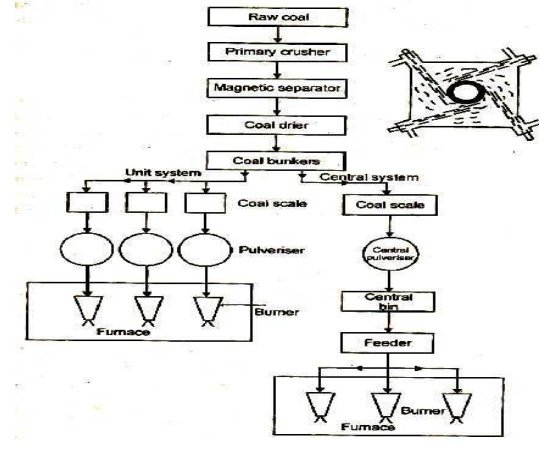

Pulverized Fuel Handling System:

Two methods are in general use to

feed the pulverized fuel to the combustion chamber of the power plant. First is

‘Unit System’ secoandis ‘Centralor

Bin System

‘.

In unit system, each burner of

the plant is fired by one or more pulverizers connected to the burners, while

in the central system, the fuel is pulverized in the central plant and then

disturbed to each furnace with the help of high pressure air current. Each type

of fuel handling system consists of crushers, magnetic separators, driers,

pulverizing mills, storage bins, conveyors and feeders.

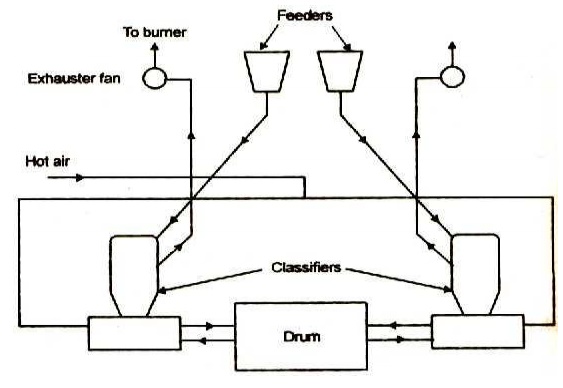

Ball Mill

A line diagram of ball mill using

two classifiers is shown in figure. It consists of a slowly rotating drum which

is partly filled with steel balls. Raw coal from feeders is supplied to the

classifiers from where it moves to the drum by means of a screw conveyor. As

the drum rotates the coal get pulverized due to the combine impact between coal

and steel balls. Hot air is introduced into the drum. The powdered coal is

picked up by the air and the coal air mixture enters the classifiers, where

sharp changes in the direction of the mixture throw out the oversized coal

particles. The over-sized particles are returned to the drum. The coal air

mixture from the classifier moves to the exhauster fan and then it is supplied

to the burners.

Ball And Race Mills

In this mill the coal passes

between the rotating elements again and again until it has been pulverized to

desired degree of fineness. The coal is crushed between two moving surfaces,

namely, balls and races. The upper stationary race and lower rotating race

driven by a worm and gear hold the balls between them. The raw coal supplied

falls on the inner side of the races. The moving balls and races catch coal

between them to crush it to a powder. The necessary force needed for crushing

is applied with the help of springs. The hot air supplied picks up the coal

dust as it flows between the balls and races and then enters the classifier. Where

oversized coal particles are returned for further grinding.

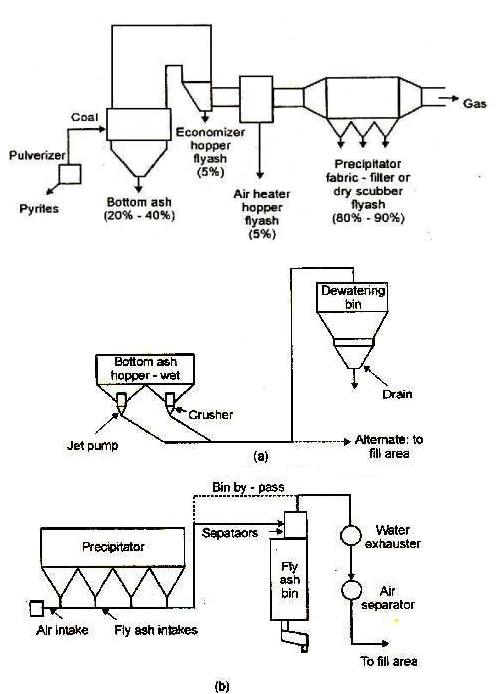

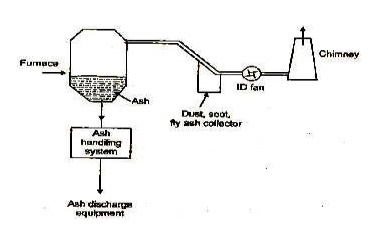

ASH HANDLING SYSTEM:

Boilers

burning pulverized coal (PC) have bottom furnaces. The large

ash particles are

collected under the furnace in a

water-filled ash hopper, Fly ash is collected in dust collectors with either an

electrostatic precipitator or a baghouse. A PC boiler generates approximately

80% fly ash and 20% bottom ash. Ash must be collected and transported from

various points of the plants as shown in figure. Pyrites, which are the rejects

from the pulverizers, are disposed of with the bottom ash system. Three major

factors should be considered for ash disposal systems.

1. Plant

site

2. Fuel

source

3. Environmental

regulation

Needs for water and land are

important considerations for many ash handling systems. Ash quantities to be

disposed of depend on the king of fuel source. Ash storage and disposal sites

are guided by environmental regulations.

1 Ash Handling Equipment:

Mechanical means are required for

the disposal of ash. The handling equipment should perform the following

functions: 1. Capital investment, operating and maintenance charges of the

equipment should be low. 2. It should be able to handle large quantities of

ash. 3. Clinkers, shoot, dust etc. create troubles.The equipment should be able

to handle them smoothly.4. The equipment used should remove the ash from the

furnace, load it to the conveying system to deliver the ash to dumping site or

storage and finally it should have means to dispose of the stored ash. 5. The

equipment should be corrosion and wear resistant.

Hydraulic System

In this system, ash from the

furnace grate falls into a system of water possessing high velocity and is

carried to the sumps. It is generally used in large power plants. Hydraulic

system is of two types, namely, low pressure hydraulic system used for

intermittent ash disposal figure. Figure shows hydraulic system.

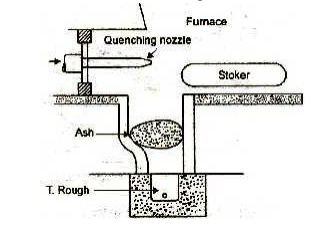

Water-Jetting System

Water jetting of ash is shown in

figure. In this method a low pressure jet of water coming out of quenching

nozzle is used to cool the ash. The ash falls into trough and is then removed.

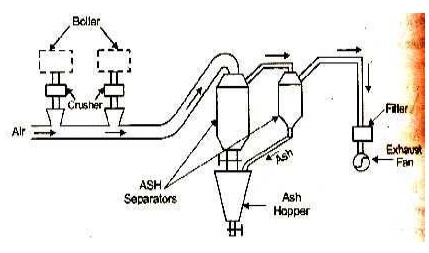

Pneumatic System

In this system ash from the

boiler furnace outlet falls into a crusher where a lager ash particles are

crushed to small sizes. The ash is then carried by a high velocity air or steam

to the point of delivery. Air leaving the ash separator is passed through

filter to remove dust etc. So that the exhauster handles clean air which will

protect the blades of the exhauster.

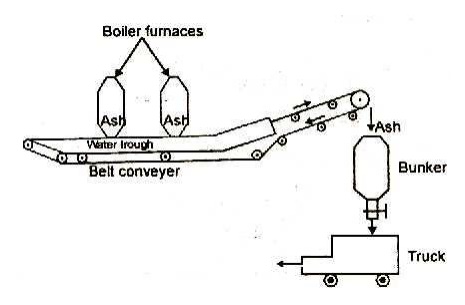

Mechanical system

Figure

shows a mechanical ash handling system.

In this system ash cooled by

water seal falls on the belt conveyor and is carried out continuously to the

bunker.

Related Topics