Chapter: Electrical Engineering and Instrumentation : Induction Machines and Synchronous Machines

Starting Methods of Induction Motor

Starting Methods

The single-phase IM has no starting torque, but has resultant torque, when it rotates at any other speed, except synchronous speed. It is also known that, in a balanced two-phase IM having two windings, each having equal number of turns and placed at a space angle of 900(electrical), and are fed from a balanced two-phase supply, with two voltages equal in magnitude, at an angle of 900, the rotating magnetic fields are produced, as in a three-phase IM. The torque-speed characteristic is same as that of a three-phase one, having both starting and also running torque as shown earlier. So, in a single-phase IM, if an auxiliary winding is introduced in the stator, in addition to the main winding, but placed at a space angle of 900 (electrical), starting torque is produced. The currents in the two (main and auxiliary) stator windings also must be at an angle of 900, to produce maximum starting torque, as shown in a balanced two-phase stator. Thus, rotating magnetic field is produced in such motor, giving rise to starting torque. The various starting methods used in a single-phase IM are described here.

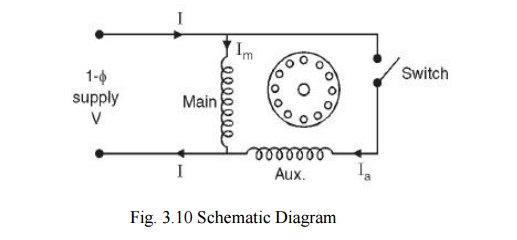

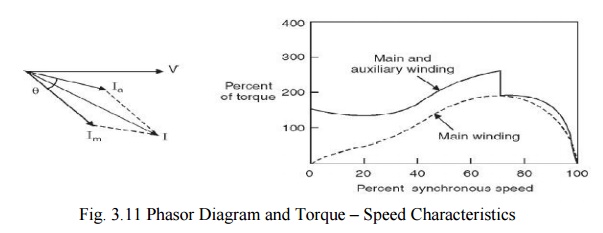

1. Resistance Split-Phase Motor

The schematic (circuit) diagram of this motor is given in Figure 3.10. As detailed earlier, another (auxiliary) winding with a high resistance in series is to be added along with the main winding in the stator. This winding has higher resistance to reactance ratio as compared to that in the main winding, and is placed at a space angle of from the main winding as given earlier. The phasor diagram of the currents in two windings and the input voltage is shown in Figure 3.11. The switch, S (centrifugal switch) is in series with the auxiliary winding. It automatically cuts out the auxiliary or starting winding, when the motor attains a speed close to full load speed. The motor has a starting torque of 100−200% of full load torque, with the starting current as 5 -7 times the full load current. The torque-speed characteristics of the motor with/without auxiliary winding are shown in Figure 3.11.The change over occurs, when the auxiliary winding is switched off as given earlier. The direction of rotation is reversed by reversing the terminals of any one of two windings, but not both, before connecting the motor to the supply terminals. This motor is used in applications, such as fan, saw, small lathe, centrifugal pump, blower, office equipment, washing machine, etc

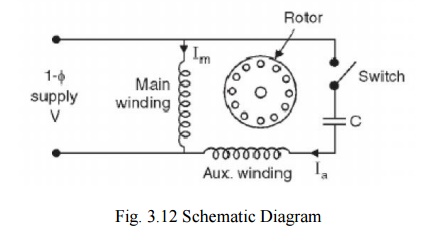

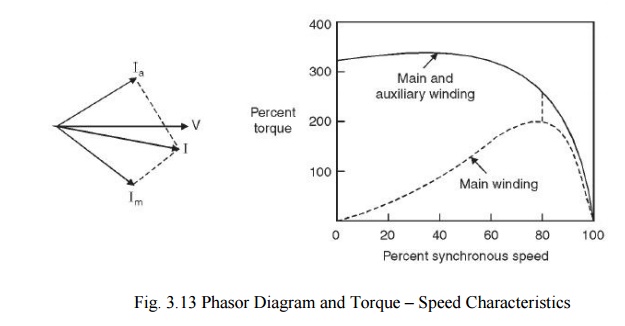

2. Capacitor-Start Motor

The schematic (circuit) diagram of this motor is given in Figure 3.12. It may be observed that a capacitor along with a centrifugal switch is connected in series with the auxiliary winding, which is being used here as a starting winding. The capacitor may be rated only for intermittent duty, the cost of which decreases, as it is used only at the time of starting. The function of the centrifugal switch has been described earlier. The phasor diagram of two currents as described earlier, and the torque-speed characteristics of the motor with/without auxiliary winding, are shown in Figure 3.13. This motor is used in applications, such as compressor, conveyor, machine tool drive, refrigeration and air-conditioning equipment, etc.

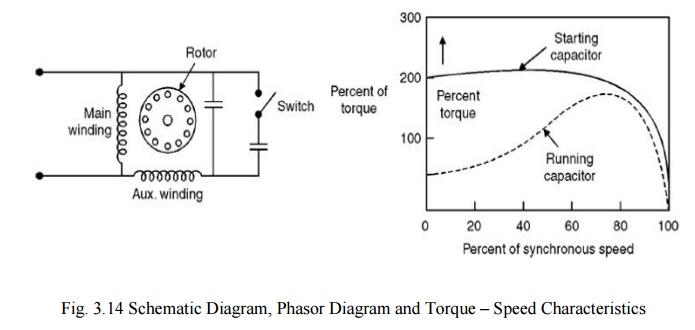

3. Capacitor-start and Capacitor-run Motor

The schematic (circuit) diagram of this motor is given in Figure 3.14. In this motor two capacitors Cs for starting, and Cr for running, are used. The first capacitor is rated for intermittent duty, as described earlier, being used only for starting. A centrifugal switch is also needed here. The second one is to be rated for continuous duty, as it is used for running. The schematic (circuit) diagram and the phasor diagram of two currents in both cases, and the torque-speed characteristics with two windings having different values of capacitors, are shown in figure 3.14. Hence, using two capacitors, the performance of the motor improves both at the time of starting and then running. This motor is used in applications, such as compressor, refrigerator

Beside the above two types of motors, a Permanent Capacitor Motor with the same capacitor being utilized for both starting and running, is also used. The power factor of this motor, when it is operating (running), is high. The operation is also quiet and smooth. This motor is used in applications, such as ceiling fans, air circulator, blower, etc.

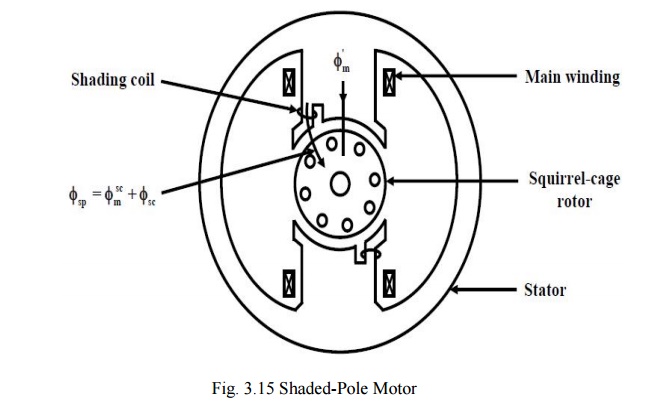

4. Shaded-pole Motor

A typical shaded-pole motor with a cage rotor is shown in figure 3.15. This is a single-phase induction motor, with main winding in the stator. A small portion of each pole is covered with a short-circuited, single-turn copper coil called the shading coil. The sinusoidally varying flux created by ac (single-phase) excitation of the main winding induces emf in the shading coil. As a result, induced currents flow in the shading coil producing their own flux in the shaded portion of the pole.

The reversal of the direction of rotation, where desired, can be achieved by providing two shading coils, one on each end of every pole, and by open-circuiting one set of shading coils and by short-circuiting the other set.

The fact that the shaded-pole motor is single-winding (no auxiliary winding) self-starting one, makes it less costly and results in rugged construction. The motor has low efficiency and is usually available in a range of 1/300 to 1/20 kW. It is used for domestic fans, record players and tape recorders, humidifiers, slide projectors, small business machines, etc. The shaded-pole principle is used in starting electric clocks and other single-phase synchronous timing motors.

Related Topics