Chapter: Aquaculture Engineering : Removal of Particles

Sludge production and utilization - Aquaculture Engineering

Sludge production

and utilization

Removal of particles from the water creates sludge comprising

water and particles. The water content and dry matter (DM) or total solids (TS)

in the sludge depend on the particle filter used. To give an idea of the amount

of sludge (faeces) created by the fish, the following estimate can be used: for

each kilogram of feed eaten by rainbow trout 20% faeces are produced, measured

on 100% DM basis.40 This value, however, depends on a number of

factors including feed composition, feed type, fish size and fish species, and

will therefore vary. If the feed con-version rate is above unity and

traditional dry feed is used, there will be feed loss that goes directly to the

outlet in addition to the sludge produced from the faeces. This also shows the

importance of correct feeding and avoiding feed losses.

Example

How much sludge is produced per kg

commercial dry feed supplied to rainbow trout if the purification efficiency of

the filter is set to 50% measured as DM? What happens if the feed conversion

rate increases to 1.2?

Per kg feed supplied, 200 g of sludge

is produced and the filter collects 50% of this. This means that the amount of

sludge collected per 1 kg feed supplied is 100 g.

If the feed conversion rate is 1.2

only 0.83 kg of the 1 kg feed supplied will be utilized for growth, while the

rest will be feed loss. Calculating that 20% of the feed eaten is converted to

faeces, this represents 0.17 kg. If this is added to the feed loss, the amount

is 0.17 + 0.17 = 0.34 kg. If collecting 50% of this, the amount collected per kg

feed supplied will be 170 g.

The actual amount of sludge can be much higher; the percentage

DM in the collected sludge depends on the filter system used. In a mechanical

filter it is mainly a consequence of how the straining cloth is back-washed,

whether using air or water, and if water, the amount. Normally the percentage

DM in the sludge is 0.1–1%, but in special filters it might be up to 5%. It is

advantageous to have as much DM in the sludge as possible, which means that

back-flushing with water is disadvantageous. The only reason for back-flushing

with water is that it is an effective system. A large proportion of DM in the

sludge reduces the amount that must be further treated and transported; the

sludge is therefore often dewatered to increase the percentage DM. Filter

presses and special centrifuges can be employed for dewatering.16,23

The sludge may also be sent to a settling system for further separation of

particles.26 Vertical sedimentation in a cone has been used and

increased the DM in the sludge to 7–10%.

Normally the sludge must be stored for a period to accumulate

enough so that it can be collected economically. A particle removal system will

there-fore include storage tanks for the sludge.

To make it possible to store the sludge, it must be stabilized.

If the sludge is immediately placed in an open container with access to air at

the surface, an uncontrolled decomposition process (rotting) will take place.

This will smell and have negative effects on the development of bacteria and

the content of nutrients. Subsequent use of the sludge can be inhibited because

of this. Correct decomposition makes the nutrients in the sludge available for

plants so that it can be used as fertilizer on agri-culture land. Sludge from

fish farms is rich in organic nitrogen (3–9% of DM) and phosphorus (1–4% of

DM). In addition, the concentration of heavy metals is usually below regulatory

limits.41This makes the sludge useful as a fertilizer.

Untreated sludge may contain pathogenic (negative)

micro-organisms such as viruses, bacteria and parasites.42When infected

sludge is spread on agricultural land and there is drainage to lakes or rivers

pathogenic micro-organisms could be transferred to the local fish strains.

Birds could also transfer pathogenic micro-organisms from the sludge to lakes.

Therefore the sludge must be treated to inactivate the negative micro-organisms

before it is spread; this is not achieved with uncontrolled decomposition.

There are several ways to inactivate pathogenic micro-organisms

in the sludge; wet or dry com-posting is commonly used. Another method is to

add lime to raise the pH in the sludge and hence inactivate the

micro-organisms. Both these methods will also stabilize the sludge so that it

can be stored, and make it suitable for use as fertilizer on agricultural land,

a very important use for sludge, normally a good fertilizer because of the high

nutrient content.

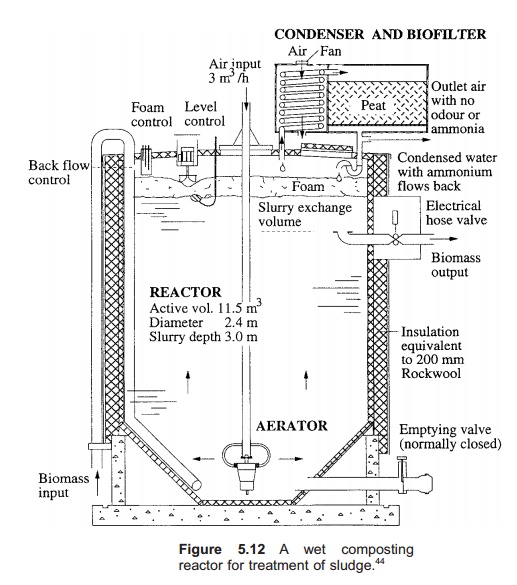

When composting sludge, controlled aerobic decomposition occurs.

Due to the low content of DM, wet or liquid composting is employed for fish

farming sludge (Fig. 5.12). Before composting the

sludge may be mixed with manure or municipal sludge. In a

community there may be a centrally installed reactor. The sludge is poured into

a con-tainer where air is added, for instance through an injector pump. In

addition the sludge is circulated around in the tank so air comes into contact

with all the sludge. This results in controlled bacterial development in the

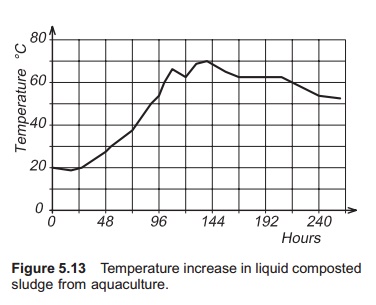

container which decomposes the organic matter. The process is thermophilic, so

the temperature increases depending on the sludge. For fish farming the sludge

is energy-rich, experimentally producing 3.1 kWh/kg DM,44 and the temperature

rises to 60–70°C (Fig. 5.13). This high temperature is maintained for some time

so that the pathogenic micro-organisms are inactivated and the sludge is

stabilized for storage. To get rid of the smell developed during the composting

process it is an advantage to include a smell filter, for instance made of

peat, through which all gases emitted by the composting process have to pass.43–45

Overall, the composting process will result in biological stabilization of the

sludge, removal of the major odour compounds, increased availability of some

plant nutrients, nitrification and denitrification, and improved waste

consistency.

If the process is run without access to oxygen, anaerobic

digestion, also known as fermentation, will occur. As for composting, naturally

occurring micro-organisms in the sludge are utilized. It is important that no

air is supplied, so anaerobic degeneration of the organic substances will

occur. Normally some heating of the sludge will be neces-sary to allow the

micro-organisms to develop. The sludge is stored in a closed digester during

this process. For animal manure it takes 10–35 days; a high fat content reduces

the time necessary. This fermentation produces methane gas; the process is

therefore also called biogas fermentation. In addi-tion to the production of

biogas, there will also be a reduction in offensive odours, a breakdown of

organic mass, a reduction of pathogens and an improved fertilizing value due to

easier availability of the nutrients.42The biogas can be used for heating

or electricity production, so there is actu-ally a positive output from the

process. Sludge that has gone through this process can be stored for later use

as fertilizer for agricultural land.

Adding lime (CaO) or slaked lime (Ca(OH)2) to the

sludge to increase the pH, will also stabilize and disinfect the sludge. In

experiments with sludge from fish farming it was shown that by increasing the

pH to 12 and maintaining this value for 7 days, more than 99.9% of the

pathogenic viruses and bacteria were killed.41The sludge produced is

well suited for use as organic fertilizer.

When establishing a system for particle removal it is therefore

necessary to think not only about the particle filter itself, but also sludge

production and its utilization. This includes tanks for sludge collec-tion

(Fig. 5.14).

Related Topics