Economic Activities - Secondary Activities | 12th Geography : Chapter 4 : Economic Activities

Chapter: 12th Geography : Chapter 4 : Economic Activities

Secondary Activities

Secondary

Activities

Secondary

sector transforms the raw materials obtained from the primary sector into consumer

goods. So it consists of manufacturing and industrial activities. Since it adds

value for the raw materials, it is also called as value addition sector. Industries

consume large quantities of energy and require factories and machinery to convert

the raw materials into goods and products. The secondary sector supports both the

primary and tertiary sectors.

Factors affecting location of Industries

1. Availability of raw-materials or nearness to raw-materials: Availability of raw materials or nearness to raw materials is a primary factor which governs location of industries. An industry is located in a place where raw materials are available in abundance and at cheaper rates. It is more so for the weight loosing and bulky raw materials. For example, oil refinery factories are established at Visakhapatnam because oil is imported through Vizag port.

2.

Availability of power: Availability

of power is another important factor

of concentration or location of industries. In olden days steam was used for running

industries. As a result industry is established near the coal mines. But with the

invention of electricity, today industries are located in any place where electricity

is available. Industries like aluminum units are located near the hydroelectric

projects.

3. TransportcostsTransport costs also influence the location of industries. Industries

incur transport costs for bringing raw-materials and for sending the finished goods

into the markets. It is economical to start an industry near the area where transport

costs are minimum and low. Raw-materials which are heavy and occupy large place,

require huge cost for transporting them. So an industry must be located near the

area where the transport costs are minimal.

4. Nearness to the market: This is a chief factor governing the location of an industry in modern period. Several

advantages are secured when an industry is established near the market.

5. Availability of labour: Labour is required for organizing the productive affairs of

an industry. The entrepreneurs like to start industries in those areas where labour

is abundantly available. For example The growth of cotton textile industry near

Bombay is due to the availability of cheap labour.

6. Government policy: The policy of government also influences the location of industries. The Government

may establish an industry on political considerations by giving several incentives.

It provides finance, land, water, and transport and communication facilities in

backward regions with a view to developing them. It also provides tax concession,

marketing consultancy, export and import facilities.

7. Availability of capital: Capital is the most essential factor for the establishment

of an industry in a locality.

Weber’s Theory of Location

Weber has developed an industrial location

emphasising the least cost principle. This is based on assumptions relating to transport

costs and other conditions. From his theory, industrial locations for three different

situations are made clear.

Assumptions:

1. Some resources

are available only in certain regions. Yet, resources such as water are ubiquitous

(present everywhere).

2. Markets

are found only in specific places.

3. Transport

costs are determined based on the weight of the raw materials and distance of transfer.

4. There

is competition in the markets for the commodities produced at the industry.

5. Humans

use their discretion in their consumer behaviour in relation to the industrial commodities.

Based on these assumptions, together

with the notion of high profits with least costs and imagination, Weber describes

his theory of industrial location.

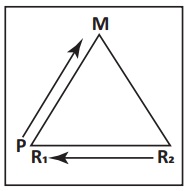

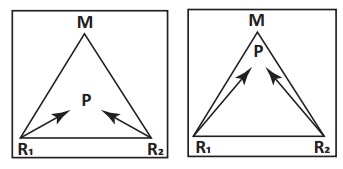

Weber uses a triangular structure to

elaborate on his theory of industrial location using least transport cost principle.

The two corners of the triangle defined by the base line represent the places where

raw materials are found (R1 and R2). The market (M) is at the apex of the triangle.

In the figure below, R1 and R2 are resource locations, consisting of two types of

resources. M is the market and P is the industrial location.

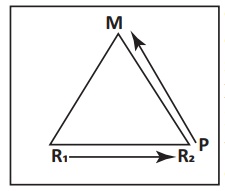

As the logic behind Weber’s location

indicates, some industries produce finished products which lose weight (weight losing

raw materials). In this case, the transport cost for raw materials transfer to the

industrial location is higher than the transport cost of moving finished products

from industrial location to market. It is because the waste from raw materials at

the industrial site will be high. Hence, it is profitable to have industry at the

raw materials’ locations.

If industry is located at the raw material source R1, then raw material R2 must be transported to industrial location R1 and the finished products must be transported to the market M. This results in transport costs. Likewise the industry could be located at R2, too. But if it is located at M, R1 and R2 resources must be transported to market M. This would also involve transport costs. If on the other hand, the industry is located half way between R1 and R2, and then the transport cost to bring the raw materials from R1 and R2 is equal. Transport cost involved in transporting the finished products to the Market decreases because of small distance to market M (if transport cost is assumed to increase with distance).

In the final analysis, the transport

cost for raw materials to the industrial location P and the finished products to

market M from P together is the least when industry is located at P. There is thus

a chance for increased profit for the industry.

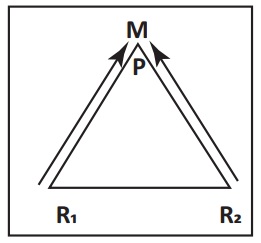

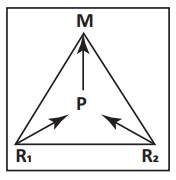

The triangle at top left represents a location where distance to be covered by transport is at minimum, the triangle at the top right illustrates the location of a ‘weight – losing industry’ and the triangle at the bottom left represents the location of a ‘weight – gaining industry’. Hence, the location of industry at P is an ‘optimal industrial location’.

As the industry is located at a point

between the raw materials locations, transport cost to transfer bulky raw materials

is reduced considerably. The transport cost for transferring the finished products

from the industry to the market is also small. In such a context, Weber believes

that it is profitable to set up the industry at a location in between the industry.

There are some industries which manufacture finished products gaining weight in the process. The transport cost between raw materials location and industry is lower than the transport cost of finished products from industrial location to the market. It is logical therefore to locate the industry at the market. According to Weber, this location is more profitable to the industry than any other. The Weber’s location theory is that it is based on the transport cost. Nevertheless, this theoryof industrial location is considered superior to other industrial location theories for its logical conclusion.

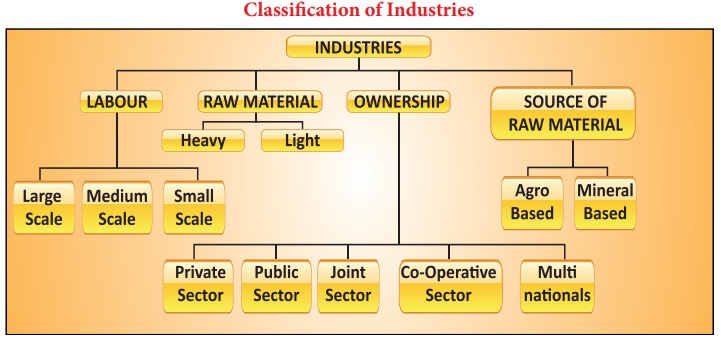

Classification of Industries

On the Basis of Labour

Large

Scale Industries

Industries which employ a large number

of labourers with huge capital are called large-scale industries. Cotton and jute

textile industries are large scale industries.

Small

Scale Industries

Industries which employ a small number

of labourers with small investments are called small scale industries. They include

nut & bolt making, coir making, plastic bags industries, dying industry, match

box making, weaving industry are some examples for small scale industries

Cottage

Industries

Those industries whose labour force consists

of family units or individuals working at home with their own equipments are called

cottage industries. It is a small and often informally organized industry. The industries

like weaving and pottery are the examples this category. On the Basis of size of

raw-Material and Finished Goods

Heavy

Industries

Industries which use heavy and bulky

raw-materials and produce products of the same category are called heavy industries.

Iron and steel industry presents a good example of heavy industries.

Light

Industries

The light industries use light raw-materials

and produce light finished products. Electric fans, sewing machines are light industries.

On the basis of Ownership

Private Sector Industries

Industries owned by individuals or firms

such as Bajaj Auto or TISCO situated at Jamshedpur are called private sector industries.

Public Sector Industries

Industries owned by the state and its

agencies like Bharat Heavy Electricals Ltd., or Bhilai Steel Plant or Durgapur Steel

Plant are public sector industries.

Joint Sector Industries

Industries owned jointly by the private

firms and the state or its agencies such as Gujarat Alkalies Ltd., or Oil India

Ltd. fall in the group of joint sector industries.

Co-operative Sector Industries

Industries owned and run co-operatively

by a group of people who are generally producers of raw materials of the given industry

such as a sugar mill owned and run by farmers are called co-operative sector industries.

On the Basis of Source of Raw Materials

Agro Based Industries

Agro based industries are those industries

which obtain raw-material from agriculture. Cotton textile, jute textile, sugar

and vegetable oil are representative industries of agro-based group of industries.

Mineral Based Industries

The industries that receive raw materials

primarily from minerals such as iron and steel, aluminium and cement industries

fall in this category.

Pastoral-Based Industries

These industries depend upon animals

for their raw material. Hides, skins, bones, horns, shoes, dairy, etc. are some

of the pastoral-based industries.

Forest Based Industries

Paper card-board, lac, rayon, resin,

tanning of leather, leave- utensils, basket industries are included in this type

of industries.

Classification based on Nature of products

Based on the nature of products it is

classified into basic industries and consumer goods. Basic industries are manufacturing

goods by using them as raw materials are basic industries. For example Iron and

steel machines for textile industry. Consumer industries are producing goods for

consumers. For example, Television, soap, biscuits, etc

Related Topics