Chapter: Civil Engineering : Building Components and Structures

Roof

Roof

Roof is the upper most portion of the building

which protects the building from rain, wind and sun. Various types of roofs

used may be divided broadly into three types:

1. Flat roofs

2. Pitched roofs

3. Shells and folded plates.

Flat roofs are used

in plains where rainfall is less and climate is moderate. Pitched roofs are

preferred wherever rainfall is more. Shells and folded plate roofs are used to

cover large column free areas required for auditoriums, factories etc. Brief

description of these roofs is presented below:

1. Flat Roofs:

These roofs are nearly flat. However slight slope (not more than 10°) is given

to drain out the rain water. All types of upper storey floors can serve as flat

roofs. Many times top of these roofs are treated with water proofing

materials-like mixing water proofing chemicals in concrete, providing coba concrete.

With advent of reliable water proofing techniques such roofs are constructed

even in areas with heavy rain fall.

The advantages of flat roofs

are:

(a) The roof can be used as a terrace for

playing and celebrating functions.

(b) At any

latter stage the roof can be converted as a floor by adding another storey.

(c) They can suit to any shape of the building.

(d)

Over-head water tanks and other services can be located easily.

(e) They can be made fire proof easily

compared to pitched roof.

The disadvantages of flat

roofs are:

(a) They cannot cover large column free

areas.

(b) Leakage

problem may occur at latter date also due to development of cracks. Once

leakage problem starts, it needs costly treatments.

(c) The dead weight of flat roofs is

more.

(d) In

places of snow fall flat roofs are to be avoided to reduce snow load.

(e) The

initial cost of construction is more. (f) Speed of construction of flat

roofs is less.

Types of Flat Roofs:

All the types listed for upper floors can be

used as flat roofs.

Pitched Roofs: In the areas of heavy rain falls

and snow fall sloping roof are used. The slope of roof shall be more than 10°.

They may have slopes as much as 45° to 60° also. The sloped roofs are known as

pitched roofs. The sloping roofs are preferred in large spanned structures like

workshops, factory buildings and ware houses. In all these roofs covering

sheets like A.C. sheet, G.I. sheets, tiles, slates etc. are supported on

suitable structures.

The pitched roofs

are classified into (a) Single roofs

(b) Double

or purlin roofs (c) Trussed roofs.

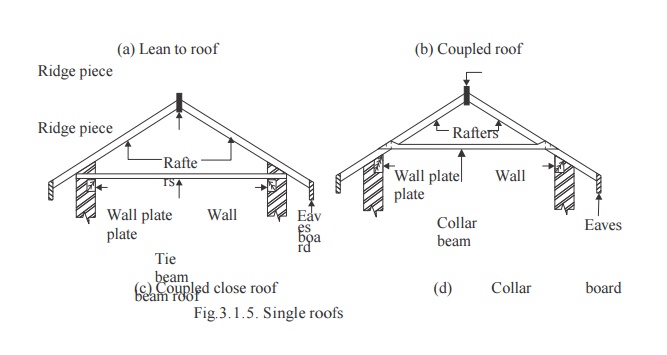

(a)

Single Roof: If the span of roof is less than 5 m the following types of

single roofs are used.

(i) Lean to

roofs (ii) Coupled roofs

(iii)

Coupled-close roof (iv) Collar beam roof

In all these roofs

rafters placed at 600 mm to 800 mm spacing are main members taking load of the

roof. Battens run over the rafters to support tiles. Figure 8.13 shows various

types of single roofs.

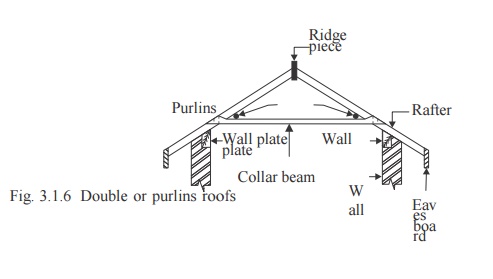

(b) Double or Purlin Roofs: If span exceeds, the cost of rafters increase and single roof

becomes uneconomical. For spans more than 5 m double purlin roofs are

preferred. The intermediate support is given to rafters by purlins supported

over collar beams. Figure 3.1.6 shows a typical double or purlin roof.

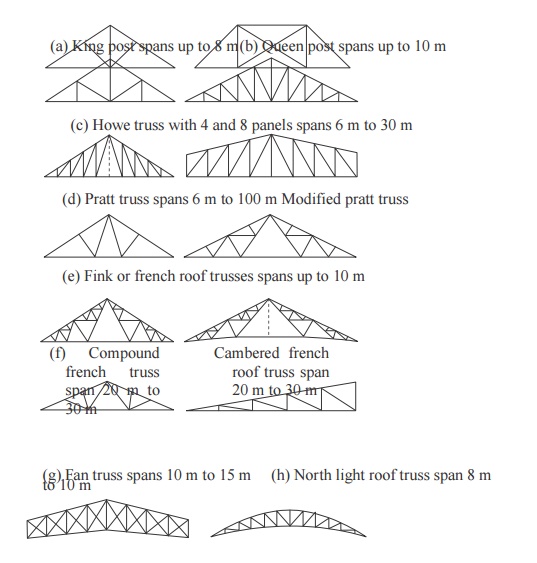

(c)

Trussed Roof: If span is more, a frame work of

slender members are used to support sloping roofs. These frames are

known as trusses. A number of trusses may be placed lengthwise to get wall free

longer halls. Purlins are provided over the trusses which in turn support roof

sheets. For spans up to 9 m wooden trusses may be used but for larger

spans steel trusses

are a must. In case of wooden trusses suitable carpentry joints are made to

connect various members at a joint. Bolts and straps are also used. In case of

steel trusses joints are made using gusset plates and by providing bolts or

rivets or welding.

Depending upon the span, trusses of different

shapes are used. End of trusses are supported on walls or on column. Figure

3.1.7 shows different shapes of trusses used.

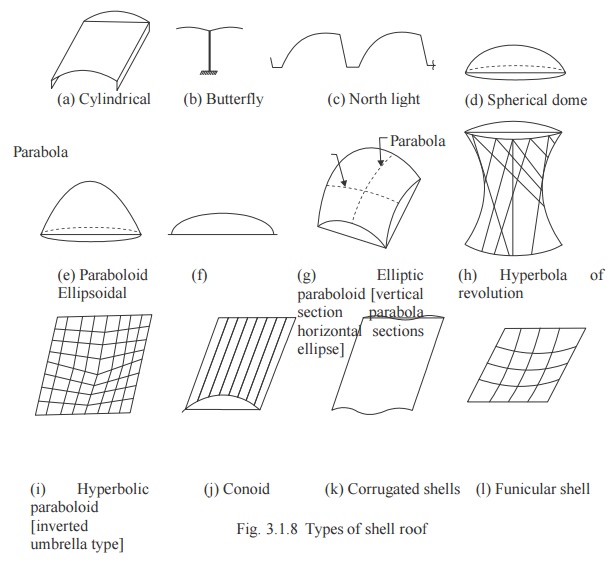

3. Shells and

Folded Plate Roofs: Shell roof may be defined as a curved surface, the

thickness of which is small compared to the other dimensions. In these roofs

lot of load is transferred by membrane compression instead of by bending as in

the case of conventional slab and beam constructions. Caves are having natural

shell roofs. An examination of places of worships built in India, Europe and

Islamic nations show that shell structures were in usage for the last 800 to

1000 years. However the shells of middle ages were massive masonry structures

but nowadays thin R.C.C. shell roofs are built to cover large column free

areas. Figure 3.1.8 shows commonly used shell roofs.

Advantages and

Disadvantages of Shell Roofs

Advantages of shell roofs are:

(a) Good

from aesthetic point of view (b) Material consumption is quite less (c)

Form work can be removed early

d) Large

column free areas can be covered.

Disadvantages are:

(a) Top surface is curved and hence

advantage of terrace is lost.

(b) Form work is costly.

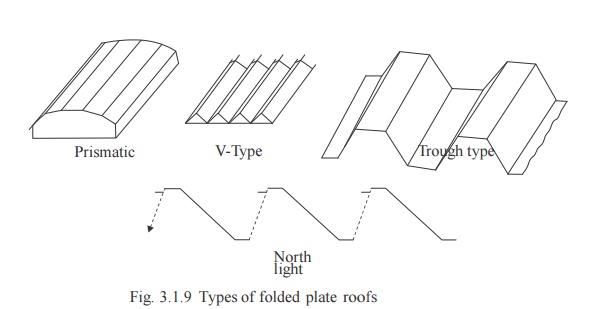

Folded plate roofs may be looked as

slab with a number of folds. These roofs are also known as hipped plates,

prismatic shells and faltwerke. In these structures also bending is reduced and

lot of load gets transferred as membrane compression. However folded plates are

not so efficient as shells. Figure 3.1.9shows typical folded plate roofs.

Fig. 3.1.9 Types of folded plate roofs

Advantages and

Disadvantages of Folded Plate Roofs Over Shell Roofs

Advantages

(a) Form work required is relatively

simpler.

(b) Movable form work can be employed.

(c) Design involves simpler calculations.

Disadvantages are:

(a) Folded plate consume more material

than shells.

(a)

Form work can be removed after 7

days while in case of shells it can be little earlier.

Roof Coverings for Pitched Roofs

Various types of covering materials are

available for pitched roofs and their selection depends upon the climatic

conditions, fabrication facility, availability of materials and affordability

of the owner. Commonly used pitched roof covering materials are:

(a) Thatch (b) Shingle

(c) Tiles (d) Slates

(e) Asbestos cement (A.C.) sheets ( f ) Galvanised

iron (G.I.) sheets

(a) Thatch

Covering: These coverings are provided for small spans,

mainly for residential buildings in villages. Thatch is a roof covering

of straw, reeds or similar materials. The thatch is well-soaked in water or

fire resisting solution and packed bundles are laid with their butt ends

pointing towards eves. Thickness varies from 150 mm to 300 mm. They are tied

with ropes or twines to supporting structures. The supporting structure

consists of round bamboo rafters spaced at 200 mm to 300 mm over which split

bamboos laid at right angles at close spacing. It is claimed that reed thatch

can last 50 to 60 years while straw thatch may last for 20–25 years.

The advantage of

thatch roof is they are cheap and do not need skilled workers to build them.

The disadvantages are they are very poor fire resistant and harbour rats and

other insects.

(b)

Shingles: Wood shingles are nothing but the split or sawn

thin pieces of wood. Their size varies from 300 mm to 400 mm and length

from 60 mm to 250 mm. Their thickness varies from 10 mm at one end to 3 mm at

the other end. They are nailed to supporting structures. They are commonly used

in hilly areas for low cost housing. They have very poor fire and termite

resistance.

(c) Tiles: Various clay tiles are manufactured in different localities.

They serve as good covering materials. Tiles are supported over battens

which are in turn supported by rafters/trusses etc. Allahabad tiles, Mangalore

tiles are excellent inter-locking tiles. They give good appearance also.

(d) Slates: A slate is a sedimentary rock. Its colour is gray. It can be

easily split into thin sheets.Slates of size 450 mm to 600 mm wide, 300

mm long and 4 to 8 mm thick are used as covering materials of pitched roofs in

the areas where slate quarries are nearby. A good slate is hard, tough,

durable. They are having rough texture and they give ringing bell like sound

when struck. They do not absorb water.

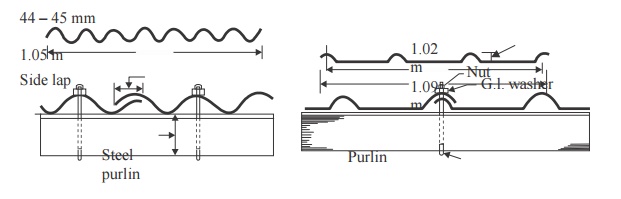

(e) A.C. Sheets: Asbestos cement is a material which consists of 15 per cent of

asbestos fibres evenly distributed and pressed with cement. They are

manufactured in sufficiently large size. The width of a A.C. sheet varies from

1.0 to 1.2 m and length from 1.75 to 3.0 m. To get sufficient strength with

thin sections they are manufactured with corrugation or with traffords fib

3.20.

They are fixed to the steel purlins

using J-bolts. The roofing is quite economical, waterproof. However not very

good thermal resistant. They are commonly used as covering materials in ware

houses, godowns or for larger halls. In auditorium etc., if these sheets are

used, false ceilings are provided to get good thermal resistance.

Related Topics