Chapter: Mechanical : Engineering Economics & Cost Analysis : Replacement And Maintenance Analysis

Replacement And Maintenance Analysis

REPLACEMENT AND MAINTENANCE ANALYSIS

Introduction

Organizations providing

goods/services use several facilities like equipment and machinery which are

directly required in their operations. In addition to these facilities, there

are several other items which are necessary to facilitate the functioning of

organizations.

All such facilities should be

continuously monitored for their efficient functioning; otherwise, the quality

of service will be poor. Besides the quality of service of the facilities, the

cost of their operation and maintenance would increase with the passage of

time.

Hence, it is an absolute necessity

to maintain the equipment in good operating conditions with economical cost.

Thus, we need an integrated approach to minimize the cost of maintenance. In

certain cases, the equipment will be obsolete over a period of time.

If a firm wants to be in the same

business competitively, it has to take decision on whether to replace the old

equipment or to retain it by taking the cost of maintenance and operation into

account.

There are two basic reasons for

considering the replacement of an equipment physical impairment of the various

parts or obsolescence of the equipment.

Physical impairment refers only to

changes in the physical condition of the machine itself. This would lead to a

decline in the value of the service rendered, increased operating cost,

increased maintenance cost or a combination of these.

Obsolescence is due to improvement

of the tools of production, mainly improvement in technology.

So, it would be uneconomical to

continue production with the same machine under any of the above situations.

Hence, the machines are to be periodically replaced.

Sometimes, the capacity of existing

facilities may be inadequate to meet the current demand. Under such situation,

the following alternatives will be considered.

ü Replacement of the existing equipment with a new one.

ü Augmenting the existing one with an additional equipment.

Types of Maintenance

Maintenance activity can be classified into two types:

ü Preventive maintenance and

ü Breakdown maintenance.

Preventive maintenance (PM) is the

periodical inspection and service activities which are aimed to detect

potential failures and perform minor adjustments or repairs which will prevent

major operating problems in future.

Breakdown maintenance is the repair

which is generally done after the equipment has attained down state. It is

often of an emergency nature which will have associated penalty in terms of

expediting cost of maintenance and down time cost of equipment.

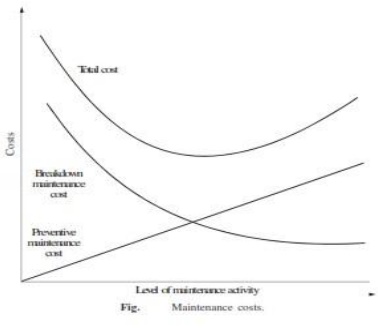

Preventive maintenance will reduce

such cost up to a point. Beyond that point, the cost of preventive maintenance

will be more when compared to the breakdown maintenance cost.

The total cost, which is the sum of

the preventive maintenance cost and the breakdown maintenance cost, will go on

decreasing with an increase in the level of maintenance up to a point.

Beyond that point, the total cost

will start increasing. The level of maintenance corresponding to the minimum

total cost is the optimal level of maintenance. The concepts are demonstrated

in Fig

Types of Replacement Problem

Replacement study can be classified into two

categories:

(a) Replacement of assets that deteriorate with time

(Replacement due to gradual failure, or wear and tear of the components of the

machines).

This can be further classified into the following types:

(i) Determination of economic life of an asset.

(ii) Replacement of an existing asset with a new asset.

(b) Simple probabilistic model for assets which fail completely

(replacement due to sudden failure).

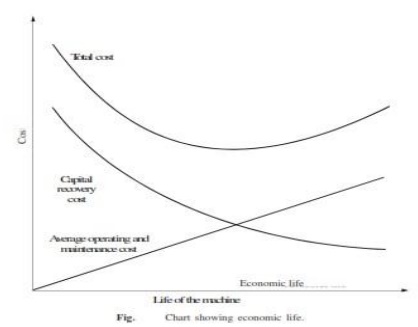

Determination of Economic Life of an

Asset

Any asset will have the following cost components:

ü Capital recovery cost (average first cost), computed from the

first cost (purchase price) of the machine.

ü Average operating and maintenance cost (O & M cost)

Total cost which is the sum of capital recovery

cost (average first cost) and average maintenance cost.

EXAMPLE

A firm is considering replacement of

an equipment, whose first cost is Rs. 4,000 and the scrap value is negligible

at the end of any year. Based on experience, it was found that the maintenance

cost is zero during the first year and it increases by Rs. 200 every year

thereafter.

(a) When should the equipment be replaced if i = 0%?

(b) When should the equipment be replaced if i = 12%?

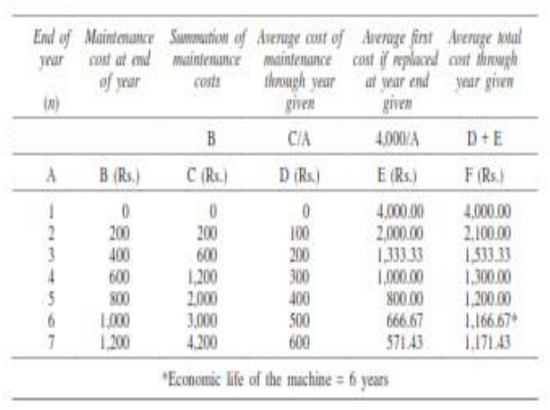

(a) When i = 0%. In this problem

(i)

First cost = Rs. 4,000

(ii)

Maintenance cost is Rs. 0 during the

first year and it increases by Rs. 200 every year thereafter.

This is summarized in column B of Table

Column C summarizes the summation of maintenance

costs for each replacement period. The value corresponding to any end of year

in this column represents the total maintenance cost of using the equipment

till the end of that particular year.

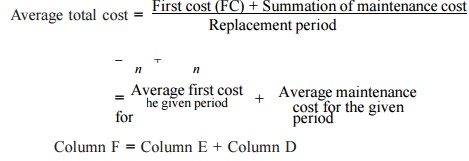

Average total cost = [ First cost (FC) + Summation

of maintenance cost ] / Replacement period

Column F = Column E + Column D

The value corresponding to any end

of year (n) in Column F represents the average total cost of using the

equipment till the end of that particular year.

For this problem, the average total

cost decreases till the end of year 6 and then it increases. Therefore, the

optimal replacement period is six years, i.e. economic life of the equipment is

six years.

(b) When interest rate, i =

12%. When the interest rate is more than 0%, the steps to be taken for getting

the economic life are summarized with reference to Table

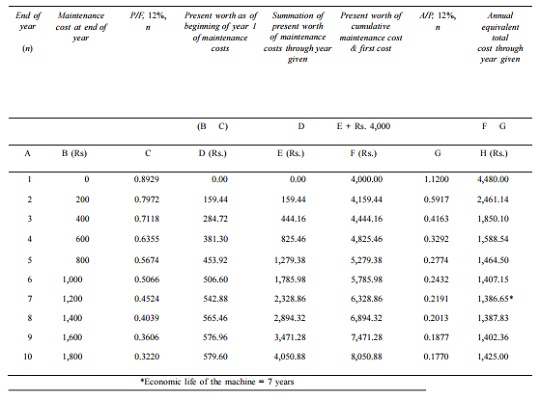

Table Calculations to Determine Economic Life (First cost = Rs. 4,000,

Interest = 12%)

The steps are summarized now:

1. Discount the maintenance costs to the beginning

of year 1.

Column D = Column B

1/ (1 + i)n

= Column B

(P/F, i, n) = Column B Column

C.

2. Find the summation of present worth of

maintenance costs through the year given (Column E = Column D).

3. Find Column F by adding the first cost of Rs.

4,000 to Column E.

4. Find the annual equivalent total cost through the

years given.

Column H = Column F i(1

+ i)n / (1 + i)n − 1

= Column F (A/P,

12%, n) = Column F Column G

5. Identify the end of year for which the annual

equivalent total cost is minimum.

For this problem, the annual equivalent total cost

is minimum at the end of year 7. Therefore, the economic life of the equipment

is seven years.

Replacement Of Exist Ing Asset With

A New Asset

In this section, the c oncept of

comparison of replacement of an existing asset with a new asset is presented.

In this analysis, the annual equivalent cost of each alternative should be co

mputed first.

Then the alternative which has the

least cost should be selected as the best alternative. Before discu ssing

details, some preliminary concepts whic h are essential for this type of

replacem ent analysis are presented.

Capital Recovery with Return

Consider the follow ing data of a machine.

Let

P = purchase priice of the machine,

F = salvage valu e of the machine at

the end of machine life,

n = life of the m achine in years, and

i = interest rate,, compounded

annually

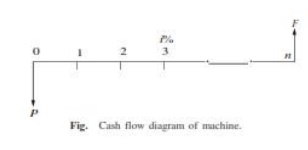

The corresponding cash flow diagram is shown in Fig

The equation for the annual

equivalent amount for the above cash flow diagram is

AE(i) = (P – F ) (A/P,

i, n) + F i

This equation represents the capital recovery

with return.

Concept of Challenger and Defender

o If an existing equipment is considered for replacement with a

new equipment, then the existing equipment is known as the defender and

the new equipment is known as challenger.

o Assume that an equipment has been purchased about three years

back for Rs. 5,00,000 and it is considered for replacement with a new

equipment. The supplier of the new equipment will take the old one for some

money, say, Rs. 3,00,000.

o This should be treated as the present value of the existing

equipment and it should be considered for all further economic analysis.

o

The purchase value of the existing

equipment before three years is now known as sunk cost, and it should

not be considered for further analysis.

EXAMPLE

Two years ago, a machine was

purchased at a cost of Rs. 2,00,000 to be useful for eight years. Its salvage

value at the end of its life is Rs. 25,000. The annual maintenance cost is Rs.

25,000.

The market value of the present

machine is Rs. 1,20,000. Now, a new machine to cater to the need of the present

machine is available at Rs. 1,50,000 to be useful for six years. Its annual

maintenance cost is Rs. 14,000. The salvage value of the new machine is Rs.

20,000.

Using an interest rate of 12%, find

whether it is worth replacing the present machine with the new machine.

Solution

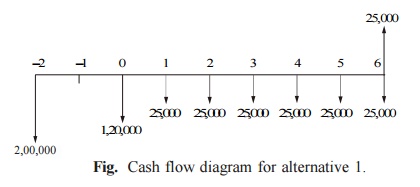

Alternative 1—

Present machine

Purchase price = Rs. 2,00,000

Present value (P) = Rs. 1,20,000

Salvage value (F) = Rs. 25,000

Annual maintenance cost (A) = Rs. 25,000

Remaining life = 6 years

Interest rate = 12%

The cash flow diagram of the present machine is

illustrated in Fig.

Fig. Cash flow diagram for alternative 1.

annual maintenance cost for the preceding

periods are not shown in this figure. The annual equivalent cost is computed as

AE(12%) = (P – F)(A/P,

12%, 6) + F i + A

= (1,20,000 – 25,000)(0.2432) + 25,000 0.12 + 25,000

= Rs. 51,104

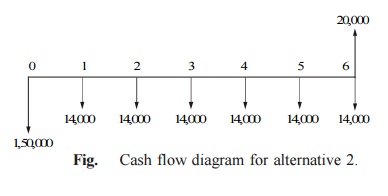

Alternative 2 —

New machine

Purchase price (P) = Rs. 1,50,000

Salvage value (F) = Rs. 20,000

Annual maintenance cost (A) = Rs. 14,000

Life = 6 years

Interest rate = 12%

The cash flow diagram of the new machine is

depicted in Fig.

Fig. Cash flow diagram

for alternative 2.

The formula for the annual equivalent cost is

AE(12%) = (P – F)(A/P,

12%, 6) + F i + A

= (1,50,000 – 20,000)(0.2432) + 20,000

0.12 + 14,000

= Rs. 48,016

Since the annual equivalent cost of

the new machine is less than that of the present machine, it is suggested that

the present machine be replaced with the new machine.

Simple Probabilistic Model For Items Which Fail Completely

Electronic items like transistors,

resistors, tubelights, bulbs, etc. could fail all of a sudden, instead of

gradual deterioration. The failure of the item may result in complete breakdown

of the system. The system may contain a collection of such items or just one

item, say a tubelight.

Therefore, we use some replacement

policy for such items which would avoid the possibility of a complete

breakdown.

The following are the replacement

policies which are applicable for this situation.

(i) Individual replacement policy. Under this policy, an item is

replaced immediately after its failure.

(ii) Group replacement policy.

Under this policy, the following decision is

made:

At what equal intervals are all the

items to be replaced simultaneously with a provision to replace the items

individually which fail during a fixed group replacement period?

There is a trade-off between the individual

replacement policy and the group replacement policy. Hence, for a given

problem, each of the replacement policies is evaluated and the most economical

policy is selected for implementation. This is explained with two numerical

problems.

EXAMPLE

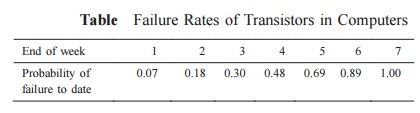

The failure rates of transistors in a computer

are summarized in Table .

The cost of replacing an individual

failed transistor is Rs. 9. If all the transistors are replaced simultaneously,

it would cost Rs. 3.00 per transistor. Any one of the following two options can

be followed to replace the transistors:

(a) Replace the transistors individually when they fail (individual

replacement policy).

(b) Replace all the transistors simultaneously at fixed intervals

and replace the individual transistors as they fail in service during the fixed

interval (group replacement policy).

Find out the optimal replacement

policy, i.e. individual replacement policy or group replacement policy. If

group replacement policy is optimal, then find at what equal intervals should

all the transistors be replaced.

Solution

Assume that there are 100 transistors in use.

Let,

pi be the probability that a transistor which was new when placed

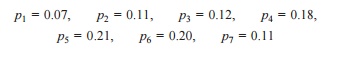

in position for use, fails during the ith week of its life. Hence,

Since the sum of pis

is equal to 1 at the end of the 7th week, the transistors are sure to fail

during the seventh week.

Assume that

(a) transistors that fail during a week are replaced just before the

end of the week, and

(b) the actual percentage of failures during a week for a sub-group

of transistors with the same age is same as the expected percentage of failures

during the week for that sub-group of transistors.

Let

Ni = the number of transistors replaced at the end of the ith

week

N0 = number

of transistors replaced at the end of the week 0 (or at the beginning of

the first week).

= 100

N1 = number of

transistors replaced at the end of the 1st week

= N0 p1 = 100 0.07

= 7

N2 = number of

transistors replaced at the end of the 2nd week

= N0 p2 + N1 p1

= 100 0.11 + 7 0.07 =

12

N3 = N0 p3 + N1 p2

+ N2 p1

= 100 0.12 + 7 0.11 +

12 0.07

= 14

N4 = N0 p4 + N1 p3

+ N2 p2 + N3 p1

= 100 0.18 + 7 0.12 +

12 0.11 + 14 0.07

= 21

N5 = N0 p5 + N1 p4

+ N2 p3 + N3 p2 + N4

p1

= 100 0.21 + 7 0.18 +

12 0.12 + 14 0.11 + 21 0.07

= 27

N6 = N0 p6 + N1 p5

+ N2 p4 + N3 p3 + N4 p2 + N5 p1

= 100 0.2 + 7 0.21

+ 12 0.18 + 14 0.12 + 21 0.11

+ 27 0.07

= 30

N7 = N0 p7 + N1 p6

+ N2 p5 + N3 p4 + N4 p3 + N5 p2

+ N6 p1

= 100 0.11 + 7 0.2

+ 12 0.21 + 14 0.18 + 21 0.12

+ 27 0.11 + 30 0.07

= 25

Calculation of

individual replacement cost

Expected life of

each transistor =

= 1 0.07 + 2 0.11 + 3

0.12 + 4 0.18

+ 5 0.21 + 6 0.2 + 7

0.11

= 4.39 weeks

Average No. of failures/week = 100/4.39 = 23

(approx.) Therefore,

Cost of individual replacement

= (No. of

failures/week Individual replacement cost/transistor) = 23 9 = Rs. 207.

Determination of group replacement

cost

Cost of transistor when replaced

simultaneously = Rs. 3

Cost of transistor when replaced individually = Rs. 9

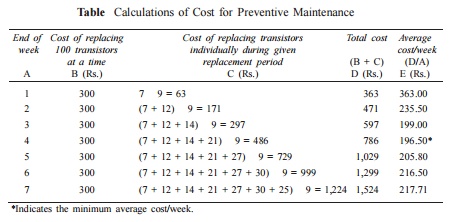

The costs of group replacement

policy for several replacement periods are summarized in Table.

Table Calculations of

Cost for Preventive Maintenance

From Table it is

clear that the average cost/week is minimum for the fourth week. Hence, the

group replacement period is four weeks.

Individual replacement cost/week = Rs. 207

Minimum group replacement cost/week = Rs. 196.50

Since the minimum

group replacement cost/week is less than the individual replacement cost/week,

the group replacement policy is the best, and hence all the transistors should

be replaced once in four weeks and the transistors which fail during this

four-week period are to be replaced individually.

Related Topics