Chapter: Mechanical : Engineering Economics & Cost Analysis : Cash Flow

Types of Maintenance

Introduction

Organizations providing goods/services use several facilities like equipment and machinery which are directly required in their operations. In addition to these facilities, there are several other items which are necessary to facilitate the functioning of organizations.

All such facilities should be continuously monitored for their efficient functioning; otherwise, the quality of service will be poor. Besides the quality of service of the facilities, the cost of their operation and maintenance would increase with the passage of time.

Hence, it is an absolute necessity to maintain the equipment in good operating conditions with economical cost. Thus, we need an integrated approach to minimize the cost of maintenance. In certain cases, the equipment will be obsolete over a period of time.

If a firm wants to be in the same business competitively, it has to take decision on whether to replace the old equipment or to retain it by taking the cost of maintenance and operation into account.

There are two basic reasons for considering the replacement of an equipment physical impairment of the various parts or obsolescence of the equipment.

Physical impairment refers only to changes in the physical condition of the machine itself. This would lead to a decline in the value of the service rendered, increased operating cost, increased maintenance cost or a combination of these.

Obsolescence is due to improvement of the tools of production, mainly improvement in technology.

So, it would be uneconomical to continue production with the same machine under any of the above situations. Hence, the machines are to be periodically replaced.

Sometimes, the capacity of existing facilities may be inadequate to meet the current demand. Under such situation, the following alternatives will be considered.

ü Replacement of the existing equipment with a new one.

ü Augmenting the existing one with an additional equipment.

Types of Maintenance

Maintenance activity can be classified into two types:

ü Preventive maintenance and

ü Breakdown maintenance.

Preventive maintenance (PM) is the periodical inspection and service activities which are aimed to detect potential failures and perform minor adjustments or repairs which will prevent major operating problems in future.

Breakdown maintenance is the repair which is generally done after the equipment has attained down state. It is often of an emergency nature which will have associated penalty in terms of expediting cost of maintenance and down time cost of equipment.

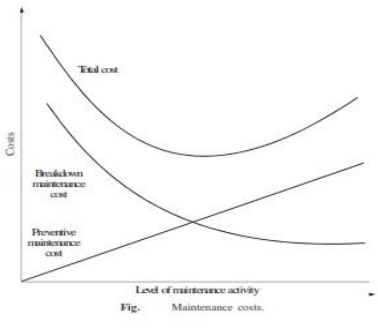

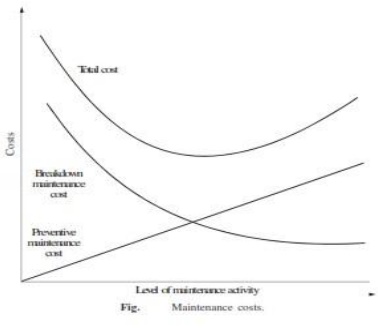

Preventive maintenance will reduce such cost up to a point. Beyond that point, the cost of preventive maintenance will be more when compared to the breakdown maintenance cost.

The total cost, which is the sum of the preventive maintenance cost and the breakdown maintenance cost, will go on decreasing with an increase in the level of maintenance up to a point.

Beyond that point, the total cost will start increasing. The level of maintenance corresponding to the minimum total cost is the optimal level of maintenance. The concepts are demonstrated in Fig

Related Topics