Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Rehabilitation and Renewal of Track

Renewal of Rail Track: Mechanized Re-laying

Mechanized Re-laying

A concrete sleeper weighs more

than 200 kg and, therefore, unlike wooden or metal sleepers, cannot be handled

easily by manual labour. Apart from being heavy, a concrete sleeper is brittle

in nature and is likely to get damaged if dropped from some height or handled

roughly. Furthermore, the conventional method of re-laying, which employs manual

labour, is quite slow and the quality of the work done is also not very good.

The need for mechanized re-laying

has been increasingly felt on account of these limitations, particularly in

view of the large-scale use of concrete sleepers on Indian Railways.

Mechanical

re-laying can be done by either one of the following methods.

(a) Semi-mechanized

re-laying using prefabricated panels, in which the main work of re-laying is

done mechanically with the help of PQRS (Plesser quick relaying system) equipment

but all other minor works are done manually.

(b) Fully

mechanized re-laying with the help of track re-laying trains.

Mechanical Re-laying using Pre-fabricated

Panels

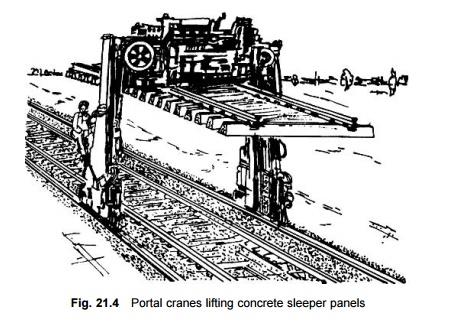

On Indian Railways, mechanical re-laying is mostly done with

the help of PQRS equipment. This equipment is manufactured by an Austrian firm

Messrs Plasser and Theurer in a factory near Faridabad, India. The equipment

basically consists of two self-propelled portal cranes, each capable of lifting

5 to 9 t. The portal cranes run on an auxiliary track with a 3.4-m gauge. Track

panels consisting of concrete sleepers, rails, and fittings are prefabricated

in the base workshop and used for re-laying the track. These prefabricated

panels are loaded in special BFR-type wagons and taken to the work site along

with portal cranes, etc. [BFR is a classification scheme for freight wagons on

IR. B indicates bogie wagon, F indicates flat car, and R indicates rapid (forced)

discharge]. The old track is dismantled and new panels are laid with the help

of portal cranes. A fully equipped train called the PQRS rake that consists of

the following parts is then taken to the site of work.

(a) Engine

(b) Coal

wagon (for recoupment of coal in the engine)

(c) Crew rest

van (for the staff to stay and rest in)

(d) Guard

compartment (for controlling the movement of the train)

(e) Mobile

workshop-cum-rest van (for urgent repairs to be done at the site)

(f) Special

wagon called BFR loaded with two portal cranes

(g) Two empty

BFRs for loading released panels

Semi-mechanized track renewal

work is then carried out in the following sequence.

1. The

auxiliary track with a 3.4-m gauge is first laid at the location where

re-laying is to be done. The rails of the existing track are also replaced with

13-m service rails.

2. A fully

equipped train comprising of the various components and loaded with prefabricated

panels is taken to the work site after setting up a traffic block, and also a

power block in the case of an electrified section.

3. The

portal cranes are then unloaded mechanically on the auxiliary track of a 3.4-m

gauge.

4. The

portal cranes are utilized to dismantle the two panels of the existing track

and load them onto empty BFRs.

5. The

ballast bed is prepared manually and levelled up to a predetermined point.

6. On the

return trip, the portal cranes are utilized to lift the pre-assembled panels of

concrete sleepers from the BFRs and lay them on the levelled ballast bed.

The procedure is repeated so that in the forward trip, the

portal cranes lift the dismantled panels and place them in empty BFRs, and on

the return trip, the portal cranes lift the two pre-assembled panels from the

loaded BFRs and lay them on the prepared bed (see Fig. 21.4).

The new panels are then connected

using fish plates, fittings, and fastenings. This method of re-laying is quick

and independent and is best suited to Indian conditions. It is possible to

achieve an average output of about 200 m per effective hour of working. About

0.8 km of re-laying can be accomplished in a 4-hr block.

Related Topics