Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Rehabilitation and Renewal of Track

Execution of Track Renewal or Track Re-laying Work

Execution of Track Renewal or Track

Re-laying Work

Track renewal or track re-laying

work can be done either manually or by mechanical means. These works involve

the following steps.

(a) Survey of

the section

(b) Preliminary

works

(c) Actual

execution of track renewal works

1 Survey of the Section

The section to be re-laid should

be surveyed in advance. The survey includes the preparation of the longitudinal

sections of the track, including the existing rail levels, at every 100 m and

at obligatory points such as level crossings, road over bridges, and overhead

crossings. The cross sections are taken at every 50 m in station yards and on

platform lines, at the site of foot over bridges, overhead watering

arrangements, etc.

2 Preliminary Works

Preliminary works are the minor

works undertaken prior to the actual work involved in track renewal. These

works include the following tasks.

(a) Unloading

track materials

(b) Ballasting

the section

(c) Fixing

level and centre-line pegs

(d) Arranging

traffic blocks

Each one

of these preliminary works is briefly discussed here.

Unloading track materials It should

be ensured that the relevant materials are unloaded at the precise

location where they are to be laid, as explained in the following.

Rails These

should be unloaded in pairs on the cess on either side of the track in the

case of single-line sections and between two tracks in the case of

double-line sections.

Sleepers The sleepers are taken

directly to the site in wagons and unloaded on the section. They

are piled in small stacks and subsequently laid at their final location.

Alternatively, they are laid 'end on' with respect to their future location,

wherever possible.

Fittings Small

fittings are likely to be lost or stolen. These should, therefore, be unloaded

in depots, gang huts, gate lodges, etc., and taken to the site as and when

required. New fish plates are graphited and fish bolts and nuts are oiled and

lubricated before use.

Ballasting the section An

adequate quantity of ballast is provided in advance and is unloaded at

the site, preferably with the help of ballast trains. Some of the ballast can

also be collected, or even procured, at the cess to avoid ballast deficiency.

The ballast should preferably be deep screened in advance.

Fixing centre-line and level pegs

Centre-line

and level pegs are provided at every 50 m.

Arranging traffic blocks The

arrangement of traffic blocks should be finalized in consultation with

the operating department. A joint memorandum of understanding should be

prepared for drawing up the exact programme of traffic blocks.

3 Actual Execution of Track Renewals Work

Once the preliminary works are

completed, the actual work of track renewal can start. This involves the

following tasks.

Setting up traffic block A traffic

block of about 2 to 4 hours is set up in order to execute the

work of track re-laying.

Dismantling old track The old

track is dismantled by removing the fish-bolts and fish plates as

well as the sleeper fastenings. The old rails and sleepers are then removed and

stacked on the side of the track opposite the new material.

Deep screening The

ballast should be deep screened if this was not done earlier along

with the other preliminary works. The ballast should be dressed and properly

levelled in accordance with the correct profile.

Linking new track After the

ballast has been laid in keeping with the correct level, the

sleepers are laid almost in their correct places, and the rails are linked over

them using proper expansion liners.

Packing new track The track

is then lifted to the correct level, aligned, and packed either

manually or with the help of machines.

4 Progress and Output

On an average, the renewal of

about 0.4 km of track can be achieved by 15 to 30 gangs in a 3 to 4 hour

traffic block. The deep screening of the ballast should, however, have been

completed ahead of re-laying work.

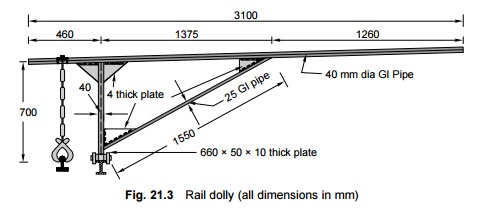

5 Rail Dolly

The rail dolly (Fig. 21.3) is an equipment used for the quick

and easy transportation of rails. It consists of a tabular frame fitted with a

chain that ends in a rail clamp. There are two double-flanged wheels with ball

bearings, which run on rails. A leverage handle is available for operating and

moving the rails. The equipment, weighing about 55 kg, is extremely useful for

carrying rails and sleepers to the site of work. In the event of an approaching

train, the rail as well as the equipment can be cleared off the track within 10

seconds.

Related Topics