Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Rehabilitation and Renewal of Track

Criteria for Rail Renewals

Criteria for Rail Renewals

The need for rail renewal can be felt because of any one of

the following reasons.

(a) Incidences

of rail fractures or failures

(b) Wear of

rails

(c) Maintaining

tracks at the prescribed standards

(d) Shortened

service life of rails

(e) Plan-based

renewal

These

criteria are discussed in detail in the subsequent sections.

1 Incidences of Rail Fractures or

Failures

Since this factor has a direct and vital bearing on the safety

of the track, it should take precedence over all other factors when deciding on

the rail renewals to be carried out. A spate of rail fractures or failures on a

particular length of a track may necessitate rail renewal. In such cases, an

ultrasonic test of the rails should be carried out, the results scrutinized,

and the section is considered for rail renewal only if the rail fractures are

high for a particular season (4% in a year or 10% overall).

2 Wear of Rails

Rail renewals may also become necessary because of excessive

wear. This wear can be of various types as a result of the following.

Limiting loss of section

Rail renewal is called for when the loss in the weight of the

section exceeds the prescribed limits given in Table 21.1. In such cases, the

rails should be tested frequently using ultrasonic rail flaw detectors because

such rails are more prone to rail failures.

The loss of weight can be assessed either directly by

measuring the actual weight or empirically by measuring the horizontal and

vertical wear of the rail.

Table 21.1 Limiting loss in weight

of rail sections

Wear due to corrosion

Rails get corroded due to the

vagaries of weather, atmospheric conditions, and chemical reactions that take

place when certain materials come in contact with rail metal, thereby resulting

in wear. Such wear is more prominent in coastal areas. Corrosion beyond 1.5 mm

in the web and the foot of the rail is specified as the criterion for rail

renewal due to corrosion.

Vertical wear

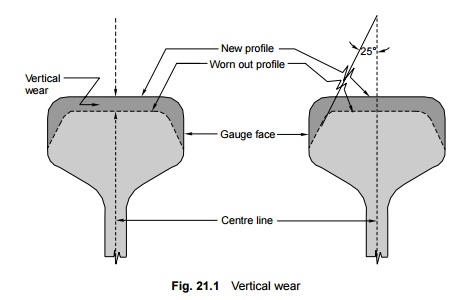

When vertical wear (Fig. 21.1) causes a reduction in the depth

of the rail head until a point beyond which there is a risk of the wheel

flanges grazing the fish plates, the rails should be renewed. The limits of

vertical wear for the different rail sections are given in Table 21.2.

Lateral wear

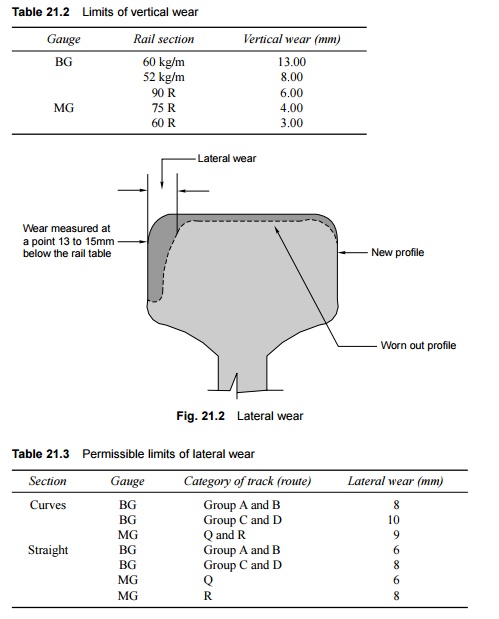

Lateral wear (Fig. 21.2) is measured at a distance of 13 to 15

mm below the rail top table. The profile of the worn out rail is recorded and

superimposed over a new profile to determine lateral wear. Excessive lateral

wear causes lateral hunting of vehicles, resulting in an uncomfortable ride.

This condition will manifest itself in the form of high values of the ride

index during oscillograph car runs. When it becomes uneconomical to maintain

such a track, through rail renewal becomes crucial. The permissible limits of

lateral wear under various conditions on the Railways are presented in Table

21.3.

3 Maintaining Tracks at the Prescribed

Standards

There may be situations in which

renewals become necessary even though the service life of a rail has not yet

expired, due to local factors such as curves, steep gradients, high speeds,

heavy axle loads, burrs, scabbing, and wear of rails that have the following

adverse effects on the track.

(a) Poor

running quality of track in spite of the extra maintenance labour engaged on

the section.

(b) Disproportionate

cost of maintaining the track under safe conditions.

(c) Poor

condition of the rail due to hogging, battering, scabbing, wheel burn, etc. and

other causes such as the excessive corrugation of the rail and which make track

maintenance difficult and uneconomical and affect riding quality.

4 Shortened Service Life of Rails

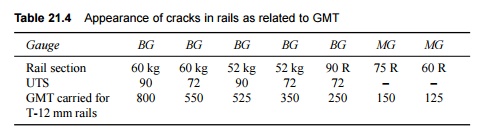

Due to the passage of moving

loads, alternating stresses are created in the rail section. The number of

reversals in the stresses are directed to the weight in gross million tonnes

(GMT) borne by the rails. The majority of rail fractures originate from fatigue

cracks, which develop after a rail has borne the threshold GMT approved for it,

as given in Table 21.4.

Table 21.4 Appearance of cracks in

rails as related to GMT

5 Plan-based Renewals

Plan-based renewals are planned

with the objective of modernizing the track structure on selected routes in the

quickest possible time. It may sometimes involve a premature renewal of the

track also.

Related Topics