Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Points and Crossings

Reconditioning of Worn Out Railway Crossings

Reconditioning of Worn Out Crossings

Generally, noses of crossings and

wing rails ungergo the maximum amount of wear in a turnout. The limiting wear

for a crossing is 10 mm, after which it is required to be replaced. A worn out

crossing is generally reconditioned at the stage when the wear is only 6 mm

(1/4"). In the case of tongue rails, the limit of vertical wear for 52-kg

and 90 R rails is 6 mm (1/4") and that of lateral wear is 8 mm. Similarly,

the limit of vertical wear for 60 R and 75 R rails is 6 mm and that of lateral

wear is 5 mm. Normally gas welding is adopted to recondition crossings at the

site itself. The sequence of operation is as follows.

1. An

advance party carries out the preliminary work in which complete and detailed

attention is paid to the turnout including through packing, replacement of worn

out fittings, tightening of fittings, squaring, spacing of sleepers, etc.

2. Both the

vertical and side wear are measured with the help of an 1.8-m straight edge.

The area where welding is to be done is cleaned, and burns, etc., are removed

using chalk.

3. The

surfaces to be welded are also cleaned, and burns, etc. are removed using

chisels.

4. Welding

is done with the help of an oxyacetylene flame using suitable welding rods

after pre-heating the surface for about 5 minutes. When the section is built up

to the thickness required, the deposit metal is hammered to make a uniform

level surface. The prepared surface is then checked with the help of a straight

edge.

5. A caution

order is sent out while the work is in progress and no speed restriction is

necessary.

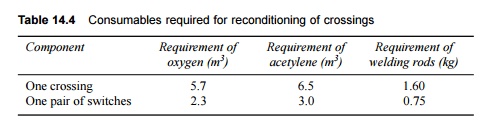

6. One

welding party consisting of one permanent way mistry (craftsman), two welders,

and six khalasis (labourers) including lookout men can weld one crossing or two

pairs of switches every working day. The consumable items required for

reconditioning work are ilsted in Table 14.4.

Table

14.4 Consumables

required for reconditioning of crossings

Related Topics