Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Points and Crossings

Inspection and Maintenance of Railway Points and Crossings

Inspection and Maintenance of Points and

Crossings

Points and crossings should be

inspected in detail, as the quality of a train ride greatly depends on their

maintenance. The following important points should be checked.

Condition of tongue rails and

stock rails There should be no wear on the top as well

as the gauge face side of the tongue rail. Badly worn out rails should be

replaced. It should be ensured that the turnout side stock rail is provided

with the requisite bend ahead of the toe of the switch; otherwise the alignment

at this spot is bound to be kinky.

Condition of fittings of tongue

and stock rails The fittings should be tight and the

spherical washers must be placed at their correct locations. The slide chairs

should be cleaned and greased with graphite for smooth operation of the points.

The fish plates should be provided with the correct amount of bend at the loose

heel joint. A gauge tie plate should be added if provisions for the same have

not been made.

Gauge and cross level at switch

assembly The gauge and cross levels should be checked for

correctness at the following locations: (i) the stock joint, (ii) 150 mm

(6") behind the toe of the switch, (iii) the mid-switch for the straight

track and for the turnout side, and (iv) the heel of the switch for the

straight track and for the turnout side.

Clearance

between stock and tongue rails at the heel of the switch The correct

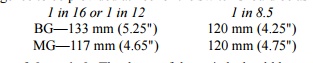

divergence to be provided at heel of the switch should be as follows:

Throw of

the switch The throw

of the switch should be as follows

Condition of crossing and tongue

rail The condition of the crossings and of the fittings

should be checked. The maximum vertical wear permitted on a point or wing rail

is 10 mm and these should be reconditioned when the wear is 6 mm. The burn

burrs should also be removed and the fittings should be tightened. The maximum

vertical wear permitted on a tongue rail is 6 mm, whereas the permitted lateral

wear is 8 mm for 90 R and 52-kg rails and 5 mm for 60 R and 75 R rails. The

tongue rail should be replaced or reconditioned before this value is reached.

The Railway Board has recently decided that the maximum vertical wear on wing

rails and the nose of the crossings should be limited to 4 mm on the Rajdhani

and Shatabdi routes and 6 mm on all other routes. The wear limits for CMS

crossings are, however, 5.5 mm for Rajdhani and Shatabdi routes and 7.5 mm for

all other routes.

Gauge and cross level of crossing

assembly The gauge and cross level should be checked at the

following locations and should always be correct: (i) 1 m ahead of the nose on

straight tracks and on turnouts, (ii) 150 mm (6") behind the ANC on

straight tracks and on turnouts, and (iii) 1 m behind the ANC on straight

tracks and on turnouts.

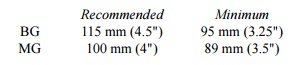

Check

rails The condition of check rails should be ascertained. Check rail

clearances should be as follows:

Maximum Minimum

BG 48 mm 44

mm

MG 44 mm 41

mm

Lead curvature The

curvature should be checked either by the offset method or by the

versine method. The curvature should be correct and uniform.

Cross levels on straight tracks

and turnouts The cross levels on straight tracks and

turnouts should be checked to see that they are correct at all places.

Sleepers The

condition of the sleepers and their fittings should be checked and unserviceable

sleepers should be replaced. The squaring and spacing of sleepers should be

proper and they should be well packed.

Ballast and drainage Enough

quantity of ballast should be available so as to provide an adequate

cushion. The drainage should be proper.

Any other defects If there

are any other defects in the layout, these should be checked and

corrected.

Special

attention is required to ensure that the sleepers are well packed, all fittings

are tightened, gauge and cross levels are properly maintained, and the wear on

the tongue rail as well as on the crossing is within permissible limits. It

should also be ensured that proper distance blocks are provided at correct

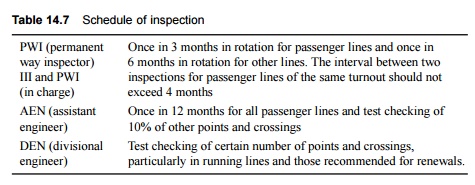

locations. The schedule of inspection followed on Indian Railways is given in

Table 14.7.

Table

14.7 Schedule of

inspection

Related Topics