Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Points and Crossings

Railway Engineering: Turnouts

Turnouts

The simplest arrangement of

points and crossing can be found on a turnout taking off from a straight track.

There are two standard methods prevalent for designing a turnout. These

are the (a) Coles method and the (b) IRS method.

These

methods are described in detail in the following sections.

The important terms used in

describing the design of turnouts are defined as follows.

Curve lead (CL) This is

the distance from the tangent point (T) to the theoretical nose of

crossing (TNC) measured along the length of the main track.

Switch lead (SL) This is

the distance from the tangent point (T) to the heel of the switch (TL)

measured along the length of the main track.

Lead of crossing (L) This is

the distance measured along the length of the main track as follows:

Lead of

crossing (L) = curve lead (CL) - switch lead (SL)

Gauge (G) This is the gauge of the track.

Heel divergence (D) This is

the distance between the main line and the turnout side at the heel.

Angle of crossing ( a ) This is

the angle between the main line and the tangent of

the turnout line.

Radius of turnout (R) This is

the radius of the turnout. It may be clarified that the radius of the

turnout is equal to the radius of the centre line of the turnout (R1)

plus half the gauge width.

R = R1

+ 0.5G

As the radius of a curve is quite

large, for practical purposes, R may be taken to be equal to R1.

Special fittings with turnouts

Some of the special fittings required for use with turnouts

are enumerated below.

Distance blocks Special

types of distance blocks with fishing fit surfaces are provided at the

nose of the crossing to prevent any vertical movement between the wing rail and

the nose of the crossing.

Flat bearing plates As

turnouts do not have any cant, flat bearing plates are provided under

the sleepers.

Spherical

washers These are special types of washers and consist of two pieces

with a spherical point of contact between them. This permits the two

surfaces to lie at any angle to each other. These washers are used for

connecting two surfaces that are not parallel to one another. Normally, tapered

washers are necessary for connecting such surfaces. Spherical washers can

adjust to the uneven bearings of the head or nut of a bolt and so are used on

all bolts in the heel and the distance blocks behind the heel on the left-hand

side of the track.

Slide chairs These are

provided under tongue rails to allow them to move laterally. These are

different for ordinary switches and overriding switches.

Grade off chairs These are

special chairs provided behind the heel of the switches to give a

suitable ramp to the tongue rail, which is raised by 6 mm at the heel.

Gauge tie plates These are

provided over the sleepers directly under the toe of the switches, and

under the nose of the crossing to ensure proper gauge at these locations.

Stretcher bars These are provided to

maintain the two tongue rails at an exact distance.

Coles method

This is a

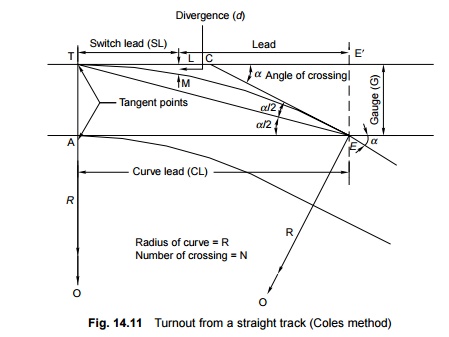

method used for designing a turnout taking off from a straight track (Fig. 14.11).

The curvature begins from a point on the straight main track ahead of the toe

of the switch at the theoretical toe of switch (TTS) and ends at the

theoretical nose of crossing (TNC). The heel of the switch is located at the

point where the offset of the curve is equal to the heel divergence.

Theoretically, there would be no kinks in this layout, had the tongue rail been

curved as also the wing rail up to the TNC. Since tongue rails and wing rails

are not curved generally, there are the following three kinks in this layout.

(a) The first

kink is formed at the actual toe of the switch.

(b) The

second kink is formed at the heel of the switch.

(c) The third

kink is formed at the first distance block of the crossing. The notations used

in Fig. 14.11 are the following.

Curve

lead (CL) = AE = TE'

Switch

lead (SL) = TL

Lead of

crossing (L) = LE'

Gauge of

track (G) = AT = EE'

Angle of

the crossing (a ) = ÐCEA = ÐECE¢

Heel of

divergence (d) = LM

Number of

the crossing (N) = cota

Radius of outer rail of turnout curve (R) = OE = OT (O

is the centre of the turnout curve)

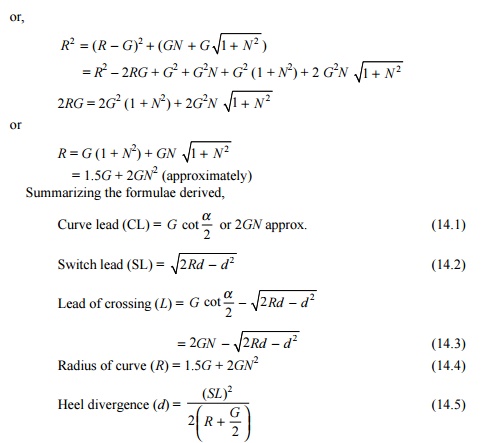

Calculations

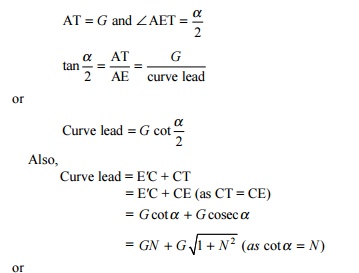

Curve lead (CL) In DATE ,

= 2GN

(approximately)

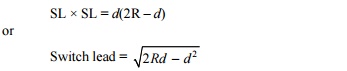

Switch lead (SL) TL is the

length of the tangent with an offset LM = D = heel divergence.

From the properties of triangles, SL × SL = d

(2R - d)

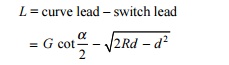

Lead of crossing (L)

L = curve

lead - switch lead

Radius of curve (R) In DAOE ,

OE = OT =

R, OA = R - G

OE2

= OA2 + AE2

OE2

= (R - G) 2 + (curve lead)2

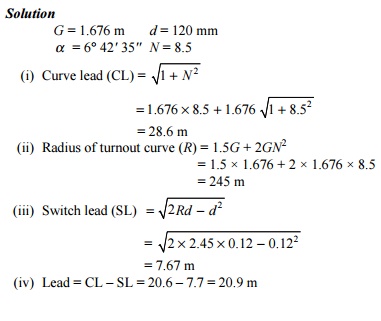

Example

14.1 Calculate the lead and radius of a 1 in 8.5 BG turnout for 90

R rails using Coles method.

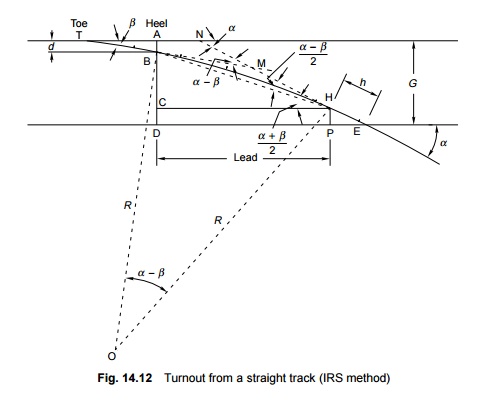

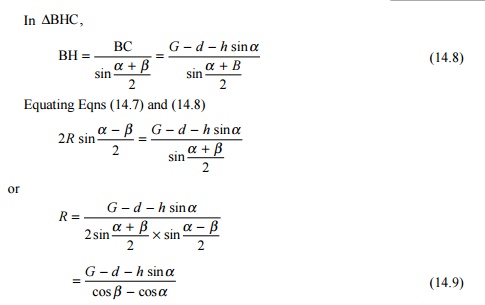

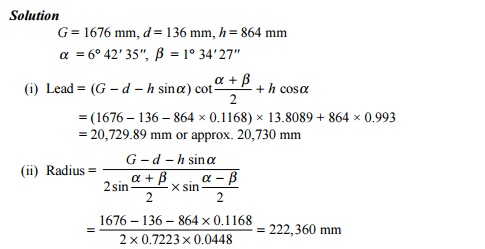

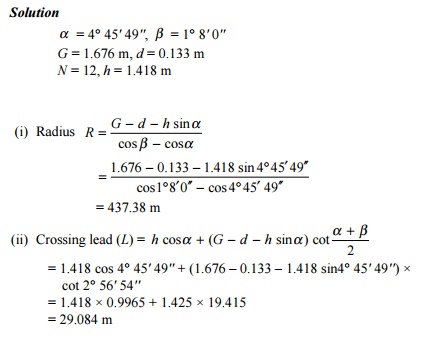

IRS method

In this

layout (Fig. 14.12), the curve begins from the heel of the switch and ends at

the toe of the crossing, which is at the centre of the first distance block.

The crossing is straight and no kink is experienced at this point. The only

kink occurs at the toe of the switch. This is the standard layout used on

Indian Railways. The calculations involved in this method are somewhat

complicated and hence this method is used only when precision is required.

Example

14.2 Calculate the lead and radius of a 1 in 8.5 BG turnout with

straight switches. Use the IRS method.

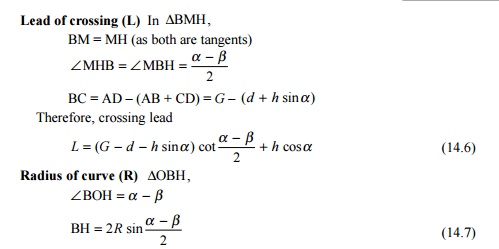

Example

14.3 A turnout is to be laid off a straight BG track with a 1 in 12

crossing. Determine the lead and radius of the turnout with the help of the

following data: heel divergence (d) = 133 mm, crossing angle (a ) = 4 o 45 ' 49'', switch angle ( b ) = 1 o 8 ' 00'', straight length between the

theoretical nose of crossing and the tangent point of crossing (h) =

1.418 m.

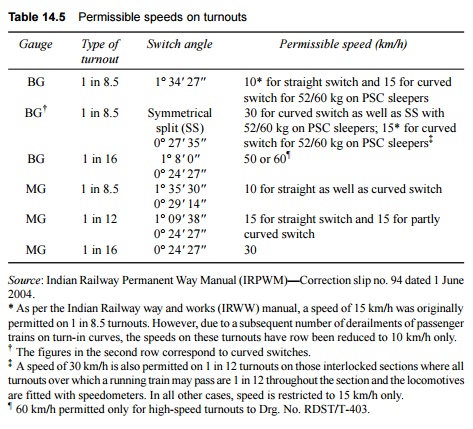

Standard turnouts and permissible speeds

On Indian Railways, normally 1 in

8.5 turnouts are used for goods trains while 1 in 12 and 1 in 16 turnouts are

used for passenger trains. Recently 1 in 20 and 1 in 24 turnouts have also been

designed by the RDSO, to be used to permit higher speeds for fast trains on the

turnout side. The maximum speeds permitted on these turnouts are given in Table

14.5.

Table

14.5 Permissible

speeds on turnouts

Source: Indian Railway Permanent Way

Manual (IRPWM)-Correction slip no. 94 dated 1 June 2004.

* As per the Indian Railway way

and works (IRWW) manual, a speed of 15 km/h was originally permitted on 1 in

8.5 turnouts. However, due to a subsequent number of derailments of passenger

trains on turn-in curves, the speeds on these turnouts have row been reduced to

10 km/h only.

†

The figures in the second row correspond to curved switches.

‡ A speed

of 30 km/h is also permitted on 1 in 12 turnouts on those interlocked sections

where all turnouts over which a running train may pass are 1 in 12 throughout

the section and the locomotives are fitted with speedometers. In all other

cases, speed is restricted to 15 km/h only.

¶ 60 km/h permitted only for high-speed

turnouts to Drg. No. RDST/T-403.

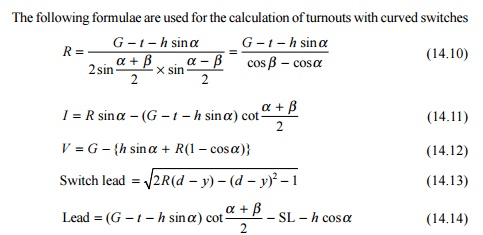

Turnout with Curved Switches

The

following formulae are used for the calculation of turnouts with curved

switches

where R is the radius of

the outer lead rail, G is the gauge, h is the lead of the

straight leg of the crossing ahead of TNC up to the TP of the lead curve, t

is the thickness of the switch at the toe, I is the distance from the

toe of the switch to the point where the tangent drawn to the extended lead

curve is parallel to the main line gauge face, V is the distance between

the main line gauge face and the tangent drawn to the lead curve from a

distance l from the toe, y is the vertical ordinate along the Y-axis,

a is the crossing angle, and b is the switch angle.

Layout of Turnout

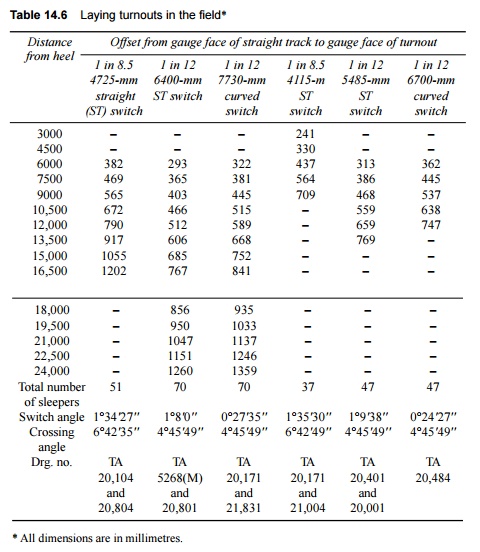

To lay out a turnout in the

field, the values of offsets from the gauge face of the straight track to the

gauge face of the turnout may be adopted from Table 14.6.

Table

14.6 Laying turnouts

in the field*

Related Topics