Chapter: Aquaculture Principles and Practices: Design and Construction of Aquafarms

Raceway farms - Design and Construction of Aquafarms

Raceway farms

Raceways are designed to provide a flow-through system to enable rearing

of much denser populations of animals. An abundant flow of good-quality,

well-oxygenated water is essential to provide respiratory requirements and to

flush out metabolic wastes, particularly ammonia. The specific flow rate

required to meet the oxygen consumption of organisms and the flushing out of

metabolites can be determined on the basis of the temperature and oxygen

concentration of the inflow water and the oxygen consumption and

ammonia/nitrogen excretion of the organisms in the raceway.

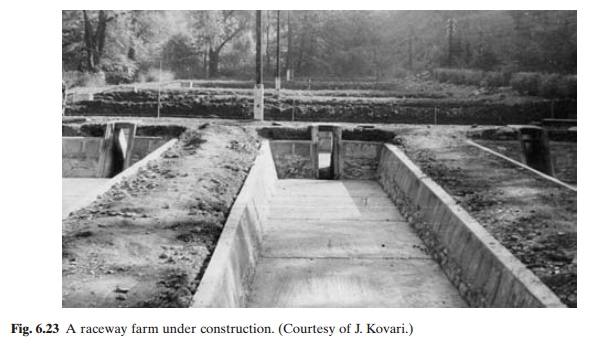

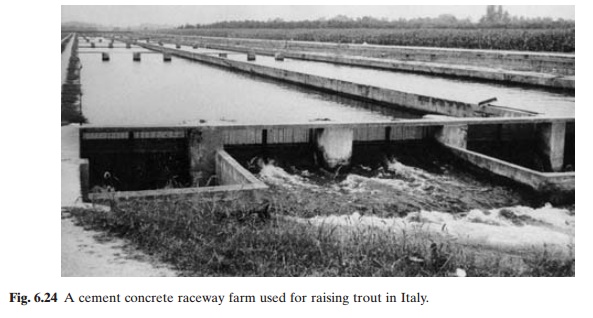

Raceways are obviously smaller in size than ponds and occupy much less space. Although earthen raceways are sometimes used, the great majority of them are made of reinforced concrete, or cement blocks (figs 6.23 and 6.24). Earthen raceways can be lined with plastic material to reduce loss of water through seepage. Just as for pond farms, site selection for a raceway farm has to be done with special care. Naturally, the most important consideration is the water supply. The main sources of water are springs, streams, deep wells or reservoirs. For trout, which is probably the most common species cultivated in raceways, there is generally a preference for spring water of uniform temperature. For raceway farming of catfish a supply of 79 l/s (1250 gal/min; US gallons) is required for every 0.4 ha (acre) of raceway (Lee, 1973). In channels 3 m (10 ft) wide at the bottom and 1.2 m (4 ft) deep with a 1 : 1 side slope, a flow of 33 l/s (530 gal/m US gallons) is often recommended. If such a flow is maintained, the water in a raceway segment of 30 m (100 ft) will be completely exchanged in about 1 hour.

In designing a raceway it is preferable to make use of the contour of

the land. A slope of 1–2 per cent is preferred so that water flowing in at one

end can be removed at the other. Each segment of a raceway can be about 30 m

long, 2.5–3 m wide at the bottom and 1–1.2m deep. A raceway farm consists of 15

to 20 segments or more. Many of them are constructed with side slopes of 1 : 1

or 1 : 0.5.

It is generally advisable to have a water supply reserve for

emergencies. A storage reservoir near the beginning of a raceway system from

where water can flow into the raceway by gravity would be most useful, in case

of pump failure. Raceways should be built straight and avoid curves, to ensure

uniform flow. As many raceways as necessary can be built alongside each other.

Many farms have a dozen or more rows. Very often the segments are built at

different levels. The general practice of discharging water through a series of

raceways carries with it the risk of unhygienic conditions developing in the

lower level segments. However, when there are not too many segments and the

water flow is sufficiently fast, the

risk is not very significant, except when there are infective diseases

in the upper raceways. In order to meet this contingency, it is necessary to

have water control structures to cut off the affected segment and discharge the

water through a separate drainage channel. Then there should also be a separate

feeder channel for each segment, very much as in a pond or tank.

It is important to have water control structures or weirs to regulate

the flow and depth of water. They could also serve to aerate the water as it

flows through. Commonly used materials for such structures are reinforced concrete,

reinforced concrete blocks, wood, sheet metal and culverts with flashboards.

They should permit discharge of water from the bottom of raceways and include

screens to prevent loss of stock. Removal of water from the bottom helps in

flushing out metabolic wastes and water low in oxygen. Other means of achieving

the flow of bottom water is through a syphon arrangement or by constructing a

vertically adjustable wide baffle on the upstream side of the weir, extending

down into the water, so that waterflows under it rather than over it. It is

essential to adjust the rate at which water is pumped or flows into a raceway

in order to prevent over-flow or emptying. For cleaning raceway bottoms in

emergencies, a suitable suction device can be used.

Related Topics