Chapter: Modern Analytical Chemistry: Uality Assurance

Quality Assessment

Quality Assessment

The written directives of a quality

control program are a necessary, but not a suffi-

cient, condition for

obtaining and maintaining an analysis in a state

of statistical control.

Although quality control directives explain how an analysis should be properly

conducted, they do not indicate

whether the system

is under statistical control. This

is the role

of quality assessment, which is the second

component of a quality assurance program.

The

goals

of quality

assessment are to determine

when a system has reached

a state of statistical control; to detect when the system has moved out of statistical control; and, if possible, to suggest

why a loss of statistical control has occurred so that corrective

ac- tions can be taken.

For convenience, the methods of quality

assessment are divided into two categories: internal methods that are coordinated within the laboratory and exter-

nal methods for which an outside agency or individual is responsible.

Internal Methods of Quality Assessment

The most useful

methods for quality

assessment are those

that are coordinated by the laboratory and that provide

the analyst with immediate feedback

about the sys- tem’s state of statistical control. Internal methods

of quality assessment included in this section

are the analysis

of duplicate samples,

the analysis of blanks, the analysis

of standard samples, and spike

recoveries.

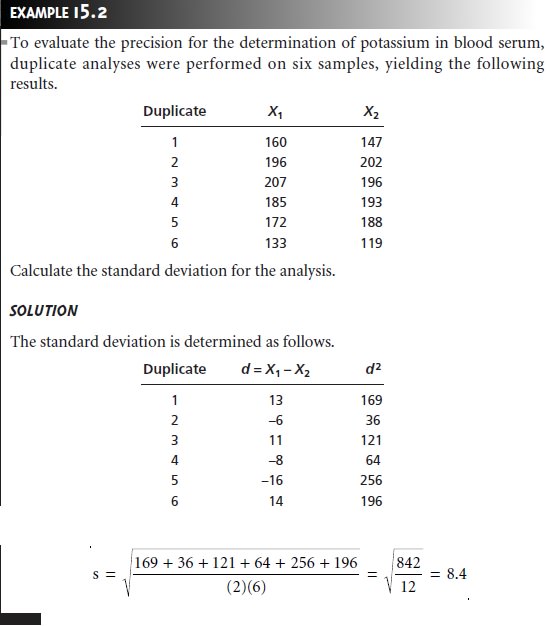

Analysis of Duplicate Samples

An effective method

for determining the precision

of an analysis is to analyze duplicate samples.

In most cases

the duplicate samples are taken from a single gross

sample (also called

a split sample),

although in some cases the duplicates must be

independently collected gross samples. The results from the duplicate samples,

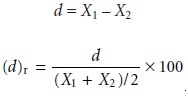

X1 and X2, are evaluated by determining the difference,

d, or the

relative difference, (d)r, between

the samples

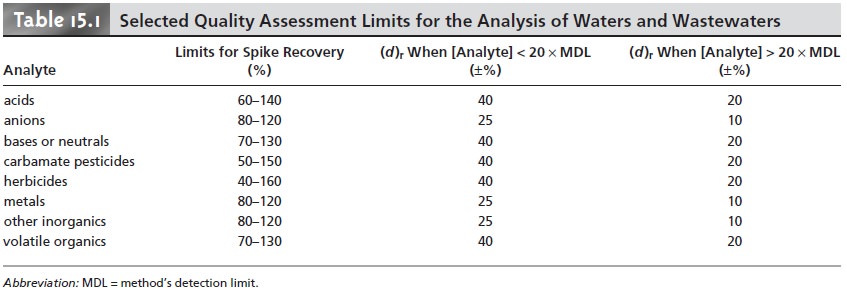

and comparing the results with accepted values,

such as those

shown in Table

15.1 for the analysis

of waters and wastewaters.

Alternatively, the results

for a set of n duplicates are

combined to estimate the standard deviation for the analysis

where di is the difference between the ith pair of duplicates. The degrees of freedom

for the standard deviation is the same as the number of duplicate samples.

If dupli- cate samples

from several sources

are combined, then

the precision of the measure- ment process must be approximately the same for each. The precision obtained

is then compared with the precision needed to accept

the results of the analysis.

The Analysis of Blanks

The

use

of

a blank was introduced

as a means of correcting the measured signal for contributions from sources other than

the analyte. The most common

blank is a method, or reagent blank,

in which an analyte-free sample, usually distilled

water, is carried through the analysis using

the same reagents, glassware, and instrumentation. Method blanks are used to identify and

correct systematic errors

due to impurities in the reagents and con-

tamination in the glassware and instrumentation. At a minimum, method blanks should be analyzed whenever new reagents are

used, although a more frequent analysis provides

an ongoing monitoring

of the purity of the reagents. A new method

blank should also

be run whenever a sample with

a high concentration of the analyte is analyzed, because

any residual carryover of the analyte

may contami- nate the glassware or instrumentation.

When samples are collected in the field, the method blank may be augmented with field and trip

blanks. A field blank is

an analyte-free sample

carried from the laboratory to the sampling

site. At the sampling site the blank

is transferred to a

clean sample container, exposing it to the local environment, preserved, and trans- ported back to the

laboratory for analysis. Field blanks are

used to identify and correct systematic errors due to sampling, transport, and analysis. Trip blanks are analyte-free samples

carried from the laboratory to the sampling

site and returned to the laboratory without

being opened. A trip blank

is used to identify and

correct systematic errors due

to cross-contamination of volatile organic

compounds during transport, handling, storage, and analysis.

Analysis of Standards

The analysis of a

standard containing a known concentra- tion

of analyte also

can be used

to monitor a system’s state

of statistical control. Ide- ally, a standard

reference material (SRM) should be used, provided

that the matrix of

the SRM is similar to that of the samples

being analyzed. A variety of appropriate

SRMs

are available from the National Institute of Standards and Technology

(NIST). If a suitable SRM is not available, then an independently prepared synthetic

sample can be used if it is prepared from

reagents of known

purity. At a minimum,

a standardization of the method is verified

by periodically analyzing

one of the cali- bration standards. In all cases,

the analyte’s experimentally determined concentra-

tion in the standard must fall within

predetermined limits if the system

is to be con- sidered

under statistical control.

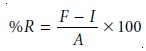

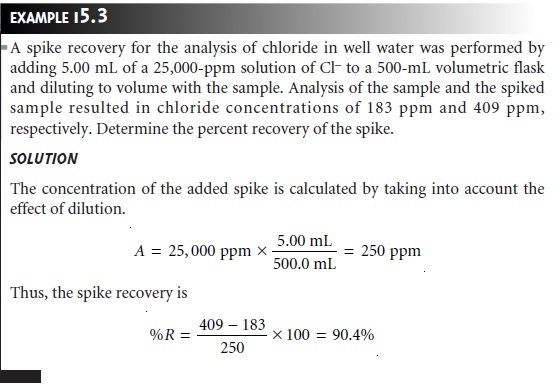

Spike Recoveries

One of the most important quality assessment tools

is the recov- ery of a known addition, or spike, of analyte to a method

blank, field blank,

or sam- ple. To determine a spike recovery, the

blank or sample

is split into

two portions, and a known amount

of a standard solution of the analyte

is added to one portion. The concentration of the analyte is determined for both the spiked, F, and

unspiked portions, I, and the

percent recovery, %R, is

calculated as

where A is the

concentration of the analyte added to the spiked portion.

Spike recoveries on method blanks

and field blanks

are used to evaluate the general performance of an analytical procedure. The concentration of analyte added to

the blank should

be between 5 and 50 times the

method’s detection limit.

Sys- tematic errors occurring during sampling and transport will result in an unaccept- able recovery for the field blank,

but not for the method

blank. Systematic errors occurring in the laboratory, however, will affect the recoveries for both the field and method blanks.

Spike recoveries for

samples are used

to detect systematic errors due to the

sample matrix or the stability of the sample

after its collection. Ideally, samples

should be spiked in the

field at a concentration between

1 and 10 times the

expected concentration of the analyte or 5 to 50 times the method’s

detection limit, whichever is larger. If the recovery

for a field spike is unacceptable, then a sample

is spiked in the laboratory and analyzed immediately. If the recovery

for the labora- tory spike is acceptable, then the poor

recovery for the

field spike may

be due to the

sample’s deterioration during storage. When the recovery for the laboratory spike also is unacceptable, the

most probable cause

is a matrix-dependent relationship be- tween the analytical signal

and the concentration of the analyte.

In this case the

samples should be analyzed by the method of standard

additions. Typical limits for

acceptable spike recoveries for the analysis

of waters and wastewaters are shown in Table

15.1.

External Methods of Quality Assessment

Internal methods of quality assessment should always be viewed with some level of

skepticism because of the potential for bias in their execution and interpretation. For this

reason, external methods

of quality assessment also play an important role in quality assurance programs. One

external method of quality assessment is the

certification of a laboratory by a sponsoring agency. Certification is based on the

successful analysis of a set

of proficiency standards prepared by the sponsoring agency. For example,

laboratories involved in environmental analyses may be re- quired

to analyze standard

samples prepared by the Environmental Protection

Agency. A second

example of an external method

of quality assessment is the volun- tary participation of the laboratory in a collaborative test sponsored by a professional organization such as the Association of Official Analytical Chemists. Finally, individuals contracting with a laboratory

can perform their own external quality assessment by submitting blind

duplicate samples and blind standard

sam- ples to the laboratory for analysis. If the results

for the quality

assessment samples are unacceptable, then there is good reason

to consider the results suspect

for other samples provided

by the laboratory.

Related Topics