Chapter: Design of Electrical Machines : Induction Motors

Performance Evaluation - Design of Induction Motors

Performance Evaluation:

Based on

the design data of the stator and rotor of an induction motor, performance of

the machine has to be evaluated. The parameters for performance evaluation are

iron losses, no load current, no load power factor, leakage reactance etc. Based

on the values of these parameters design values of stator and rotor can be

justified.

Iron

losses: Iron losses are occurring in all the iron parts due to the varying

magnetic field of the machine. Iron loss has two components, hysteresis and eddy

current losses occurring in the iron parts depend upon the frequency of the

applied voltage. The frequency of the induced voltage in rotor is equal to the

slip frequency which is very low and hence the iron losses occurring in the

rotor is negligibly small. Hence the iron losses occurring in the induction

motor is mainly due to the losses in the stator alone. Iron losses occurring in

the stator can be computed as given below.

(a) Losses in stator teeth:

The

following steps explain the calculation of iron loss in the stator teeth

(i)

Calculate the area of cross section of stator tooth

based on the width of the tooth at 1/3rd height and iron length of

the core as A'ts= b'ts x li m2

(ii)

Calculate the volume all the teeth in stator Vts

= A'ts x hts x Ss m3

(iii) Compute

the weight of all the teeth based on volume and density of the material as

Wts

= Vts x density. ( density of the material can be found in DDH) (7.8

x 10-3 kg/m3)

(iv)

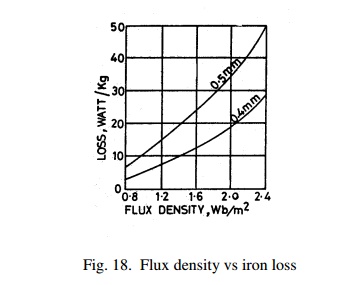

Corresponding to the operating flux density in the

stator teeth of the machine iron loss per kg of the material can be found by

referring to the graph on pp179 of DDH.

(v)

Total iron losses in teeth= Iron loss /kg x weight

of all teeth Wts ie result of (iii) x (iv)

(c)

Losses in stator core

Similar

to the above calculation of iron loss in teeth, iron loss in stator core can be

estimated.

(i) Calculate

the area of cross section of the core as

Acs = dcs x li m2

(ii)

Calculate the mean diameter of the stator core

below the slots as Dmcs= D + 2 hts + dcs m

(iii)

Compute the volume of stator core as Vcs

= Acs x π Dmcs m3

(iv)

Calculate the weight of the stator core as Wcs

= Vcs x density

(v)

Corresponding to the operating flux density in the

stator core of the machine iron loss per kg of the material can be found by

referring to the graph on pp 179 of DDH.

(vi)

Total iron losses in core = Iron loss /kg x weight

of core Wcs ie result of (iv) x (v)

Total

iron losses in induction motor = Iron loss in stator core + iron losses in

stator teeth.

In addition

friction and windage loss can be taken into account by assuming it as 1- 2 % of

the out put of the motor.

Hence

total no load losses = Total iron losses + Friction and windage loss.

Related Topics