Chapter: Design of Electrical Machines : Induction Motors

Important Short Questions and Answers: Design of Electrical Machines - Induction Motors

INDUCTION MOTORS

1.

Define slot space factor.

The

slot space factor is the ratio of conductor area per slot and slot area. It

gives an indication of the space occupied by the conductors and the space

available for insulation. The slot space factor for induction motor varies from

0.25 to

0.4.

2.

Define distribution factor or breadth factor.

It

is defined as the ratio of resultant emf when the winding is uniformly

distributed to the resultant emf when the winding is bunched in the slot.

3.

Define winding factor.

It

is defined as the product of the pitch factor and the distribution factor.

Kw

= Kp * Kd

4.

Why the low voltage winding is

placed nearer to the core and the high voltage winding in case of a core type

transformer.

Ø

Insulation

required will be less

Ø

Less

possibility for fault occurrence

Ø

Easy

to provide tapings

5.

Why is it possible to design

alternators to generate much higher voltage than dc generator?

In alternator the winding is

provided in stator and hence maximum voltage can be

provided.

In dc generator the winding is

provided in rotor and hence it is not possible to generate maximum voltage

6. Why rotating machines with aluminum

armature coils have increased leakage reactance?

Aluminum coils in armature require

more space for accommodation of conductors. Large size slots are designed.

Hence with large size slots the value of leakage reactance increases.

7. Why the harmonic leakage flux in squirrel

cage induction is motor is zero?

Since the rotor current balances the

stator current at every point there is no harmonic leakage flux.

8. Stepped core section is preferred to a

square section for transformer, give reason?

Diameter of circumscribing circle

can be reduced giving use of less copper

Due to increase in core area flux

density can be reduced which results less iron loss.

9.

Why choice of high specific loading

in the design of synchronous generators loads to poor voltage regulation?

High value of specific electric

loading will mean more number of turns per phase. This will cause high value of

leakage reactance and poor voltage regulation.

10.

Define real flux density.

It is defined as the ratio of actual

flux through the tooth to the tooth area.

11.

List the advantages and

disadvantages of using closed type of rotor slot in squirrel cage induction

motor.

Advantages:

Ø

Low

reluctances

Ø

Less

magnetizing current

Ø

Quitter

operation

Ø

Large

leakage reactance and so starting current is limited

Disadvantages:

Ø

Reduced

over load capacity

12.

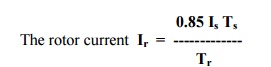

Write the expression for rotor current.

Where Ts = number of

turns per phase for stator

Tr = number of turns per

phase for rotor

Is = Stator current

13.

What are the ranges of efficiency and power factor in induction motor?

14.

The approximate efficiency of a

three phase, 50 Hz, 4 pole induction motor running at 1350 rpm is

----------------------------------------

i)

90%

ii) 40% iii) 65% iv) None of the above.

Ans

: i) 90%

15.

What is the approximate efficiency of a 60 Hz, 6 pole, 3 phase induction motor

running at 1050 rpm?

i)

72%

ii) 81.2% iii) 76.8% iv) 87.5%.

Ans

: iv) 87.5%

16.

What is integral slot winding and

fractional slot winding?

In integral slot winding, the total

number of slots is chosen such that the slots per pole are an integer, which

should be a multiple of number of phases. In fractional slot winding, the total

number of slots is chosen such that the slots per pole are not an integer.

17.

Why fractional slot winding is not

used for induction motor?

Windings with fractional number of

slots per pole per phase create asymmetrical mmf distribution around the air

gap and favour the creation of noise in the motor. Therefore, fractional

windings are not used in induction motor starter.

18.

Write the expression for length of

mean turn of stator winding?

Length of mean turn of stator, Lmts = 2L + 2.3 τ + 0.24

Where L = Stator core length

τ= pole pitch = П D / p

19.

Name the methods used for reducing harmonic torques.

Ø

Chording

Ø

Integral

slot winding

Ø

Skewing

and

Ø

Increasing

the length of air gap

20.

What is Skewing?

Skewing is twisting either the

stator or rotor core. The motor noise, vibrations, cogging and synchronous

cusps can be reduced or even entirely eliminated by skewing either the stator

or the rotor.

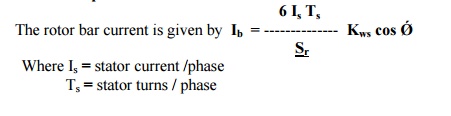

Sr = Number of rotor

slots

22.

What is full pitch and short pitch

or chording?

When the coil span is equal to pole

pitch (180 deg electrical), the winding is called full pitched winding. When

the coil span is less than pole pitch (180 deg electrical), the winding is

called short pitched or chorded.

23.

What are the different types of

stator windings in induction motor?

Ø

Mush

winding

Ø

Lap

winding and

Ø

Wave

winding

24.

How the induction motor can be

designed for best power factor?

For best power factor, the pole

pitch τ is chosen such that τ = SQRT [(0.18 L)].

25. What are the ranges of specific magnetic loading and specific electric loading in induction motor?

Specific magnetic loading = 0.3 to

0.6 Wb / m2

Specific electric loading = 5000 to 45000 amp.cond/m

26.

What are the materials used for slip

rings and brushes in induction motor?

The slip rings are made of brass or

phosphor bronze. The brushes are made of metal graphite, which is an alloy of

copper and carbon.

27.

Write the expression for output

equation and output co-efficient of induction motor.

The equation for input KVA is

considered as output equation in induction motor.

The input KVA, Q = C0 D2

L ns in KVA

Output co-efficient C0 = 11 Bav ac Kws

*10-3 in KVA/ m3 – rps.

28.

List the advantages of using open

slots.

The advantages are:

Ø

The

winding coils can be formed and fully insulated before installing and also it

is easier to replace the individual coils.

Ø

It

avoids excessive slot leakage thereby reducing the leakage reactance.

29.

Give the advantages of using

semi-enclosed stator slots.

The advantages are less air gap

contraction factor giving a small value of magnetizing current, low tooth

pulsation loss and mush quiter operation(less noise). Semi enclosed slots are

mostly preferred for induction motor.

30.

What is the maximum value of flux

density in stator teeth?

The maximum value of flux density in

stator tooth should not exceed 1.7 Wb/m2.

A high value of flux density leads

to a higher iron loss and a greater magnetizing mmf.

28.

What are the problems that occur in

induction motor due to certain combinations of stator and rotor slots?

The problems in induction motor due

to certain combinations of stator and rotor slots are

Ø

The

motor may refuse to start

Ø

The

motor may crawl at some sub-synchronous speed

Ø

Severe

vibrations are developed and so the noise will be excessive

32.

. List the rules for selecting rotor slots.

Number

of stator slots should not be equal to rotor slots satisfactory results are

obtained when Sr is 15 to 30% larger or smaller than Ss.

The

difference (Ss - Sr) should not be equal to + or - p, + or – 2p or + or – 5 p

to avoid synchronous cusps.

The

difference (Ss - Sr) should not be equal to + or - 1, + or – 2 , + or – (p+1)

or + or – (p+2) to avoid noise and vibrations.

32.

What are the main dimensions of

induction motor?

Ø

Stator

core internal diameter

Ø

Stator

core length

33.

Why induction motor is called as

rotating transformer?

The principle of operation of

induction motor is similar to that of a transformer. The stator winding is

equivalent to primary of a transformer. The rotor winding is equivalent to

short circuited secondary of a transformer. In transformer, the secondary is

fixed but in induction motor it is allowed to rotate.

35.

How slip ring motor is started?

The slip ring motor is started by

using rotor resistance starter. The starter consists of star connected variable

resistances and protection circuits. The resistances are connected to slip

rings. While starting, full resistance is included in the rotor circuit to get

high starting torque. Once the rotor starts rotating, the resistances are

gradually reduced in steps. At running condition, the slip rings are shorted

and so it is equivalent to squirrel cage rotor.

36.

What are the special features of the

cage rotor of induction machine?

Ø

The

cage rotor can adopt itself for any number of phases and poles

Ø

It

is suitable for any type of starting method except using rotor resistance

starter

Ø

It

is cheaper and rugged

Ø

Rotor

over hang leakage reactance is lesser which results in better power factor,

greater pull out torque and over load capacity.

37.

Name the materials used to insulate

the laminations of the core of induction motor.

The materials used to insulate the

laminations of the core of induction motor are kaolin and varnish.

38.

Where mush winding is used?

The mush winding is used in small

induction motors of ratings less than 5HP.

39.

What is the minimum value of slot pitch of a 3 phase induction motor?

The minimum value of slot pitch of a

3 phase induction motor is 15 mm.

40.

Write the formula for air-gap in

case of three phase induction motor in terms of length and diameter.

The length of air-gap, lg = 0.2 + 2 SQRT[(D L)] in mm

Where D and L are expressed in

meters.

40.

What is crawling and cogging?

Crawling is a phenomenon in which

the induction motor runs at a speed lesser than sub synchronous speed.

Cogging is a phenomenon in which the

induction motor refuses to start.

42.

What is harmonic induction torque and harmonic synchronous torque?

Harmonic induction torques are

torques produced by harmonic fields due to stator winding and slots.

Harmonic synchronous torques are

torques produced by the combined effect of same order of stator and rotor

harmonic fields.

43.

What is the condition for obtaining

the maximum torque in case of 3-phase induction motor?

The maximum torque occurs in

induction motor when rotor reactance is equal to rotor resistance.

44.

What is runaway speed?

The runaway speed is defined as the

speed which the prime mover would have, if it is suddenly unloaded, when

working at its rated speed.

45.

State three important features of

turbo-alternator rotors.

Ø

The

rotors of turbo-alternators have large axial length and small diameters

Ø

Damping

torque is provided by the rotor itself and so there is no necessity for

additional damper winding

Ø

They

are suitable for high speed operations and so number of poles is usually 2 or

4.

46.

Distinguish between cylindrical pole

and salient pole construction.

In cylindrical pole construction the

rotor is made of solid cylinder and slots are cut on the outer periphery of the

cylinder to accommodate field conductors.

In salient pole construction, the

circular or rectangular poles are mounted on the outer surface of a cylinder.

The field coils are fixed on the pole.

The cylindrical pole construction is

suitable for high speed operations, whereas the salient pole construction is

suitable for slow speed operations.

47.

Mention the factors that govern the design of field system of alternator.

Number of poles and voltage across each field coil

Amp-turn per pole

Copper

loss in field coil

Dissipating

surface of field coil

Specific loss dissipation and allowable temperature rise

48.

Mention the different tests that conducted in an induction motor.

No load test or open circuit test

Short circuit test or load test

49.

Give the different runaway speeds for various turbines.

50. What are the factors that are affected due

to SCR.

Voltage regulation

Stability

Short circuit current

Parallel operation

Related Topics