Chapter: Design of Electrical Machines : Induction Motors

No load current - Design of Induction Motors

No load

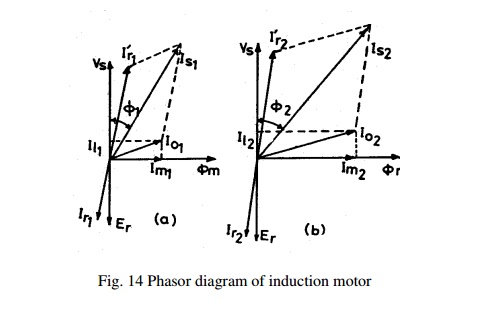

current: As seen from Fig 14, the no load current of an induction motor has two components

magnetizing component, Im and iron loss component, Iw.

Phase relation between these currents is shown in Fig. 14.

Thus the

no load current I0 = √(Im)2 + (Iw)2

amps

Magnetising

current: Magnetising current of an induction motor is responsible for producing

the required amount of flux in the different parts of the machine. Hence this

current can be calculated from all the magnetic circuit of the machine. The

ampere turns for all the magnetic circuit such as stator core, stator teeth,

air gap, rotor core and rotor teeth gives the total ampere turns required for

the magnetic circuit. The details of the magnetic circuit calculations are

studied in magnetic circuit calculations. Based on the total ampere turns of

the magnetic circuit the magnetizing current can be calculated as

Magnetising

current Im= p AT30 / (1.17 kw Tph )

where p –

no of pairs of poles, AT30 – Total ampere turns of the magnetic

circuit at 300 from the centre of the pole, Tph – Number

of stator turns per phase.

Iron loss

component of current: This component of current is responsible for supplying

the iron losses in the magnetic circuit. Hence this component can be calculated

from no load losses and applied voltage.

Iron loss

component of current Iw=

Total no load losses / ( 3 x phase voltage)

No load

Power Factor: No load power factor of an induction motor is very poor. As the

load on the machine increases the power factor improves. No load power factor

can be calculated knowing the components of no load current.

No load

power factor cosΦ0 = Iw

/ I0

Ex. While

designing the stator of a 3 phase 10 kW, 400 volts, 50 Hz, 4 pole, wound rotor induction

motor, following data are obtained.

Internal

diameter of stator = 0.19 m

Gross

length = 0.125 m

Number of

stator slots = 36

Number of

conductors/slot = 38

Dimension

of stator slot = 1.1 cm x 3.5 cm

Depth of

the stator core = 3 cm

Number of

rotor slots = 30

Dimension

of the rotor slot = 0.7 cm x 3.0 cm

Depth of

rotor core = 3.0 cm

Carter’s

coefficient for the air gap = 1.33

Based on

the above data, calculate the following performance data for this motor.

(i) Flux

per pole (ii) Iron losses (iii) Active component of no load current

(iv) No load current

(v) No

load power factor

Soln. (i) Flux per pole

Total

number of stator conductors = 36 x 38 = 1368

Stator

turns per phase Tph = 1368 /6 = 228

Assuming

star delta connection for the motor Vph = 400 volts

Assuming Eph = Vph = 400 volts,

winding factor = 0.955

Air gap

flux per pole Φ = Eph/(4.44fTph kw)

= 400/(

4.44 x 50 x 228 x 0.955)

= 0.00827

wb

(ii) Iron

losses

Total

Iron losses = Iron losses in stator teeth + Iron losses in stator core Iron

losses in stator teeth:

For the

given stator length assuming one ventilating duct of width 1cm and iron space

factor of 0.95,

Li

= (L – nd x wd)ki

= (0.125 -1

x 0.01)0.95

= 0.109 m

Diameter

at 1/3rd height, D' = D + 1/3 x hts x 2 = 0.19

+ 1/3 x 0.035 x 2 = 0.213 m

Slot

pitch at 1/3rd height = τ's = π x D' /Ss =

π x 0.213 /36 = 0.0186 m

Tooth

width at this section = b't = τ's – bs

= 0.0186 – 0.011 = 0.0076 m

Area of

the stator tooth per pole A't

= b't x li x number

of teeth per pole

= b't

x li x Ss

/p = 0.0076 x 0.109 x 36/4

= 0.00746

m2

Mean flux

density in stator teeth B't =

Φ / A't =

0.00827/ 0.00746 = 1.10 9 Tesla

Maximum

flux density in stator tooth =1.5 x 1.109

= 1.66 Tesla

Volume of

all the stator teeth = b't x li x height

of teeth x number of teeth

= 0.0076 x

0.109 x 0.035 x 36

= 0.001044

m3

Weight of

all the teeth = volume x density Assuming a density of 7.8 x 103 kg/

m3

Weight of

all the teeth = 0.001044 x 7.8 x 103 = 8.14 kg Total iron losses in

the stator teeth = Total weight x loss/kg

Iron loss

in the material at a flux density of 1.66 Tesla from graph PP-22 of DDH loss/kg

= 23 w/kg

Total

iron losses in the stator teeth = 23 x 8.14 = 187.22 watts

Iron losses in stator core : Sectional area of the

stator core = li x dc = 0.109 x 0.03 =

0.00327 m2

Mean

diameter of the stator core below the slots = 0.19 + 2 x 0.035 + 0.03 = 0.29 m

Volume of the stator core = π x D x

Acs = π x 0.29 x 0.00327 = 0.002979 m3

Weight of the stator core = 0.002979 x 7.8 x 103 = 23.23 kg

Flux

density in stator core = Φc / Acs =

0.00827/(2 x 0.00327) = 1.264 Tesla At this flux density iron loss/kg = 17

watts/kg

Iron

losses in the stator core = 17 x 23.23 = 394.91watts

Total

iron losses in the stator = 187.22 + 394.91= 582.13 watts (iii) Active

component of no load current

Assuming

the friction and windage losses as 1% of output Friction and windage loss = 100

w Total no load losses = 582.13 + 100 = 682.13 watts

Active

component of no load current = Iron loss component of current

Iw=

Total no load losses / ( 3 x phase voltage) = 682.13/( 3 x 400) = 0.568 amps

(iv)

Magnetising current: In order to calculate the magnetizing current ampere turns

required for the various parts of the magnetic circuits are to be calculated.

(a)

Ampere turns for the stator core:

Pole

pitch at he mean diameter of the stator core = π x D/ P =

π x 0.29/ 4 = 0.23 m Length of the

flux path in stator core = 1/3 x 0.23 = 0.077 m

Ampere

turns per meter at a flux density of 1.264 Tesla from graph (PP-22 of DDH) 400

AT

Hence

total ampere turns required for the stator core = 400 x 0.077 = 31

(b) Ampere

turns for the stator teeth:

Length of

the flux path in stator teeth = 0.035m

Flux

density in stator teeth at 300 from the pole centre = 1.36 Bt’

= 1.36 x 1.10 9 =1.508 Tesla Ampere turns per meter at a flux density of

1.508 Tesla (from graph PP-22 of DDH) is 1000 AT

Hence

total ampere turns for the stator teeth = 1000 x 0.035 = 35

(c)

Ampere turns for the air gap:

Length of

the air gap = 0.2 + 2√DL = 0.2

+ 2√0.19 x 0.125 = 0.51 mm Average

flux density in the air gap = Φ/ (π x DL/ P) = 0.4696 Tesla

Carter’s

coefficient for the air gap = 1.33

Air gap

flux density at 300 from the centre of the pole Bg = 1.36

x Bav

= 1.36 x

0.4696 = 0.6387 Tesla

Hence

Ampere turns for the air gap = 796000Bgkglg

ATg = 796000 x 0.687 x 1.33 x 0.51 x 10-3

= 371 AT

(d)

Ampere turns for the rotor Teeth :

Diameter

of the rotor = D -2lg =0.19 –

2 x 0.00051= 0.189 m

Diameter

at 1/3rd height form the narrow end of the teeth Dr’ = D – 2 x 2/3hrs

= 0.189 – 4/3 x 0.03 = 0.149 m

Slot

pitch at 1/3rd height = τ'r = π x Dr' /Sr

= π x 0.149 /30 = 0.0156 m

Tooth

width at this section = b'tr = τ'r – br

= 0.0156 – 0.007 = 0.0086 m

Area of

the stator tooth per pole A'tr = b'tr

x li x number

of teeth per pole

= 0.0086

x 0.107 x 30/4 = 0.0069 m2

Flux

density in rotor teeth at 300 from pole centre = 1.36 x

0.00827/0.0069 = 1.63 Tesla

Ampere

turns/m at this flux density, from graph (PP-22 of DDH) = 2800

Length of

flux path in rotor teeth = 0.03 m

Ampere

turns for the rotor teeth 2800 x 0.03 = 84

(e)

Ampere turns for the rotor core

Depth of

the rotor core dcr = 3 cm

Area of

the rotor core Acr = 0.03 x 0.107 = 0.00321 m2

Flux in

the rotor = ½ x 0.00827 = 0.004135 wb

Flux

density in the rotor core = 0.004135/0.00321= 1.29 Tesla

Ampere

turns/m at this flux density, from graph (PP-22 of DDH) = 380

Mean

diameter of the rotor core = Dr – 2 x hrs – dcr

= 0.189 – 2 x 0.03 – 0.03 = 0.099 m

Pole

pitch at this section = π x 0.099

/4 = 0.078 m

Length of

the flux path in rotor core = 1/3 x 0.078 = 0.026 m Total ampere turns for the

rotor core = 380 x 0.026 =10

Total

Ampere turns for the magnetic circuit = 31 + 35 + 371 + 84 +10 = 531 AT

Magnetising current Im = p(AT30) / (1.17 x Kw

x Tph)

= 2 x 531

/( 1.17 x 0.955 x 228)

= 4.2 amps

(v) No

load current

No load

current per phase Io = √( Iw2 + Im2)

= √( 0.562 + 4.22)

= 4.24 amps

(vi)

No load power factor cos 0

= Iw/I0 = 0.56

/4.24 = 0.132

Related Topics