Chapter: Aquaculture Engineering : Internal Transport and Size Grading

Moving fish with a supply of external energy - Methods and equipment for internal transport

Methods and equipment for internal transport

Two different principles may be used to move fish inside the farm:

· With a supply of energy

· By the use of signals or stimuli to get the fish to move voluntarily.

The first method is totally dominant, while the second is mainly the subject of research. The most common methods within each group are described below..

Moving fish with a supply of external energy

With supplied energy, the total internal transport process may again be divided into three phases:

· Crowding of the fish inside the production unit

· Vertical transport where the fish are lifted between the levels

· Horizontal transport of the fish between the units.

When moving the fish to a lower level no vertical transport is necessary; stored potential energy is used here as a source for the process. When moving fish between two equal levels, crowding can be used to force them to move.

Crowding

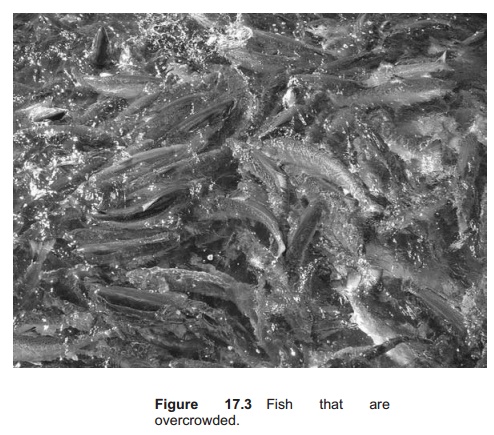

In almost all methods for vertical transport, crowding of the fish in a restricted volume is necessary. Too much crowding may, however, result in unwanted stress (Fig. 17.3). During the crowding process fish behaviour should be observed; if

· Reduction of water level (tanks, ponds)

· Reduction of available volume (ponds, tanks and cages)

If reduction of water level is to be used to crowd the fish, the outlet of the tank or pond must be designed in a way that makes drainage possible. If there is no drain, a drainage pump can be put inside the tank or pond, but this makes the handling operation more difficult. Lack of oxygen in the water may occur during this operation and supplementary oxygen may have to be supplied; the oxygen level must therefore be monitored.

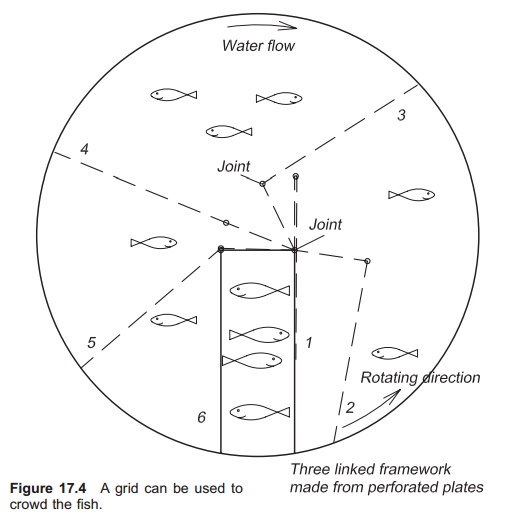

In cages, the net bag can be lifted to reduce the volume available to the fish, and through this crowd the fish. A seine net may also be used in ponds, large tanks or cages, but is less effective. In tanks, fixed or removable grids may be used to crowd the fish. A combination of collection grid and a decrease in water level can also be employed (Fig. 17.4).

Vertical transport

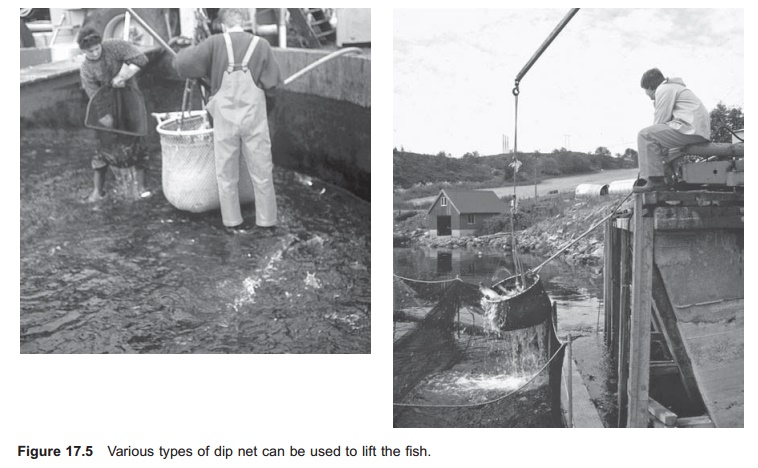

Dip net: The dip net is constructed with a round or rectangular frame with a net or tarpaulin bag inside (Fig. 17.5). Round frames are suitable for net bags to be used in cages, while rectangular frames are more suitable for use inside tanks. For a dry net, small mesh knotless netting should be used to avoid wounds. Plastic net have also been tried to reduce the possibilities for wounding.

If a tarpaulin bag is used the fish will always be in water; this is also called a wet net. A hydraulic or mechanical crane must be used to operate a wet net because of the weight. A mechanism opens the bottom to empty the wet net of fish and water.

Use of nets is labour-intensive, especially for handling larger fish. Normally wet nets are between 100 and 500 l capacity. Fish densities above 50–70% fish compared to water are normally avoided to reduce the possibility of wounding the fish.

Pumps: A pump supplies energy to the water so itis either set under pressure or vacuum which causes the water and hence the fish to move. The fish are therefore in water throughout the entire handling operation. Several systems for pumping fish are available, including centrifugal, vacuum, ejector and airlift pumps; crucially these have an open construction that does not injure the fish.

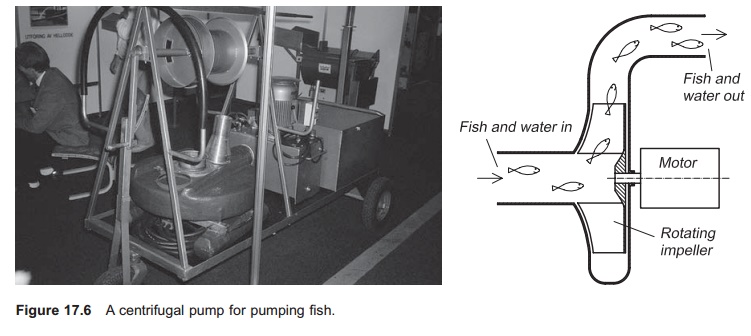

Centrifugal pump: A centrifugal pump used for pumping fish utilizes the same principle as a centrifugal pump used for pumping of water. To avoid injuring the fish it does, however, have an open impeller with large channels and no narrow passages (Fig. 17.6). Because of its construction, it is not commonly used on fish larger than 1 kg. If such a pump were to be made for 4– 5 kg fish the required dimensions of the impeller would be very large. It is normal to use submerged pumps or at least pumps with a supply pressure. Fish pumps can be made self-sucking with special adaptors. The impeller may be driven by hydraulic pressure. This makes it quite easy to move the pump around in the farm area, because only the impeller unit is moved. The pump may also be driven directly via a shaft from an electric motor. Centrifugal pumps are commonly used both in production farms and in well boats; they have been used for many years in traditional fishery well boats, among others, for pumping herring.

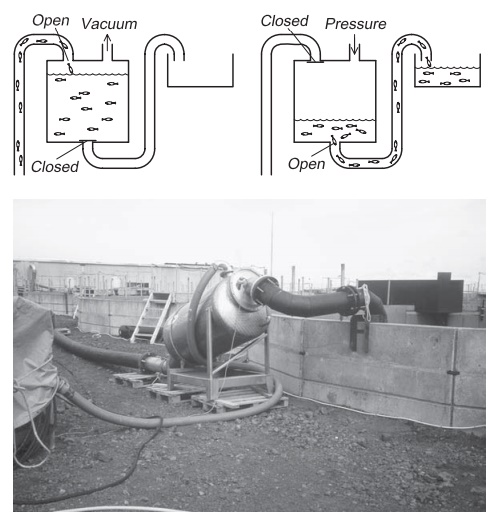

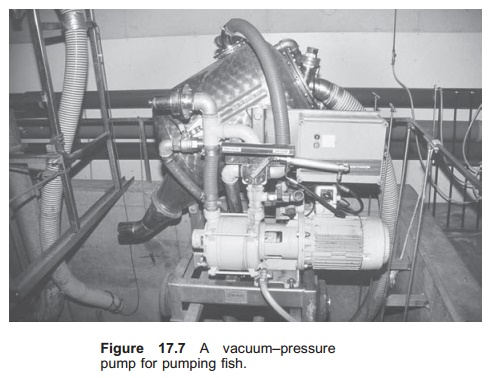

Vacuum–pressure pump: A vacuum–pressure pump consists of a tank to which inlet and outlet tubes are connected via valves (Fig. 17.7); a small pump is also attached. This pump can either pressurize the larger tank or withdraw the air from it, causing a partial vacuum. The function of the pump is first to evacuate the tank; then the valve to the inlet pipe is opened and water and fish are sucked into the tank; after this the inlet valve is closed and the tank is pressurized; lastly the outlet valve is opened and the fish are forced out through the outlet tube. The operation is repeated, and a new batch is pumped through.

The pump does not deliver water and fish continuously, because it operates in two phases: vacuum and pressure. However, two pumps can be used alternately to obtain more equal delivery of fish and water. A vacuum head of more than 5 m H2O is normally avoided to prevent injuries to the fish; use of less than 40% water relative to fish should also be avoided for the same reason. Here the manufacturer’s recommendations must be followed.

Pumps of different sizes are required for handling small fish and harvesting large fish. The difference is the size of the tank, the pipes and the pump used to evacuate and pressurized the tank. Pumps are used on farms, in well boats and in slaughterhouses.

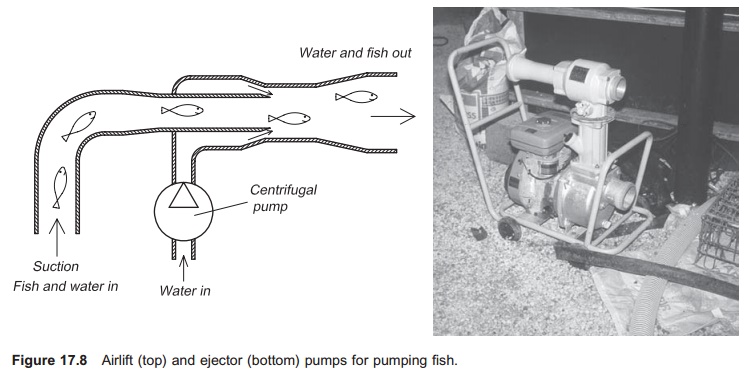

Ejector pump: In an ejector pump, a high velocity, high pressure part flow creates a region of low pres-sure (suck) in the larger main stream (Fig. 17.8). The fish travel with the water in the main stream. When the water flows past the ejector it will go from low to higher pressure. The pump can therefore deliver fish in a continuous flow of water. The pump has no moveable parts that can injure the fish. A suction head that is too high must be avoided; it is better to take a larger part of the lifting head on the pressure side. When fish have already lost scales, as occurs to young salmon during smoltification, they can easily lose more scales in these pumps, especially if the ejector is badly adjusted.

Different sized ejectors are available, adjusted to fry and to on-growing fish. The smallest size is portable and easy to move around the farm. Har-vesting of mussels has also been performed with this type of pump. Some pumps have ejectors at both ends of the pipes so it is possible to change the flow direction; these are of interest on well boats for pumping fish in and out of the well.

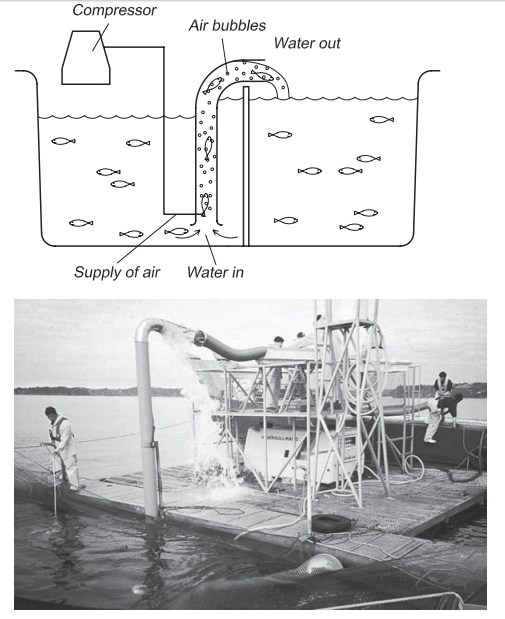

Airlift pump: An airlift pump can be used for pumping fish (Fig. 17.8). Air is added to create bubbles that rise to the surface through a vertical, water-filled pipe suspended in the fish cage or tank. The bubbles cause drag on the water particles near them and create an upward flow of water inside the pipe. This moves the fish that are in the water up through the pipe. The capacity and the lift height in such a pump depend on the depth of the water, at which depth the air is supplied and the amount of air supplied. If using airlift pumps for fish transport, there are always possibilities for super saturation of the water with nitrogen gas. Because of the short fish retention time in the pump, this will not normally result in any problems, but if the fish stay in the water for a longer period, problems may occur.

More generally, fish pumps can be used for different fish sizes from juvenile through to fish ready for harvesting. The difference is the size of the tubes or pipes. Pumps may also be used for harvesting shells and mussels from the bottom culture, especially airlift and ejector pumps.

It is very important that pumps are used according to the supplier’s recommendations. Several problems have occurred when transporting fish due to incorrect pump use; examples include fish that have been cut by valves, eyes that come out because of incorrect pressure conditions, and scale loss; they all show the importance of correct pump use. Awareness of the correct suction head is especially important.

The great advantage of pumps over other handling methods is their large capacity. Today pumps are being used increasingly in intensive aquaculture as well as in slaughterhouses.

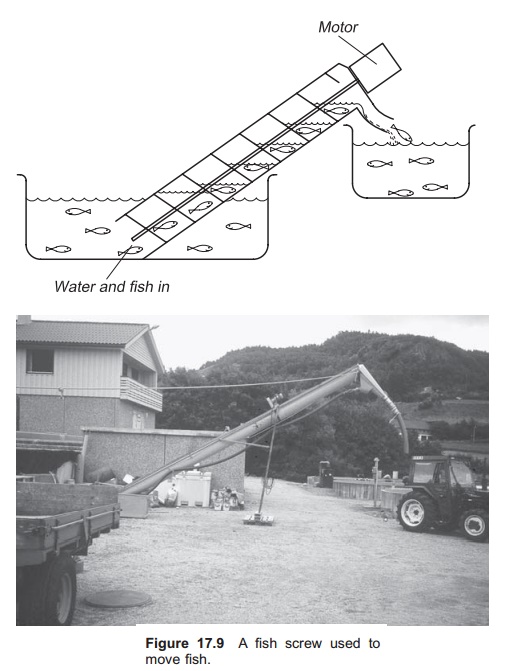

Fish screw: The fish screw, or pescalator, is basedon the Archimedes screw which was used for lifting water in ancient times (Fig. 17.9). A screw is fixed inside a pipe which has a belt around its circumference. The belt is further connected to a small electric motor; when the motor starts the belt will rotate as will the pipe and therefore the screw relative to

it. This is not a traditional screw which rotates; the pipe in which the screw is fixed rotates. Rotation of the pipe will result in lifting of water and the fish within it. The fish appear to be lying with water in small basins. Fish must be crowded around the inlet of the pipe for the screw to be filled with fish. Hence the screw may be placed in a well where the fish are automatically crowded. Another solution is to use a special perforated tank around the inlet, which again stands inside the fish basin or pond. A dip net may be used to lift the fish up and into a perforated tank. The lift height achieved depends on the length of the screw. To avoid damage to the fish it is not recommended to have an angle towards the horizontal plane of more than 40°. Usually the screw length is between 3 and 6 m, while the diameter of the pipe varies between 30 and 45 cm. An area around the tank or pond where the screw is to be used is required, so that the screw can be repositioned. Such screws are commonly used in tanks with low water levels and in ponds.

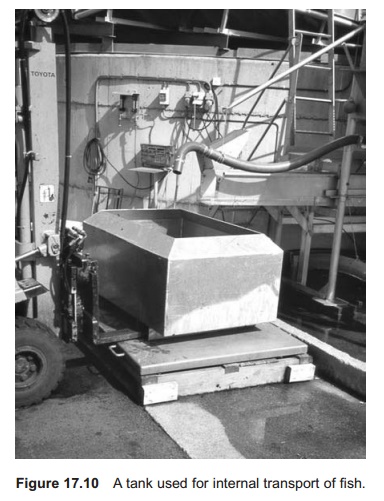

Transport tanks: The transport tank is specially designed with smooth surfaces and angles to avoid wounding the fish during transport (Fig. 17.10). The fish have first to be transferred from their ordinary production unit to the transport tank, for instance by use of a dip net or by pumping the fish. It is necessary to have mechanical equipment, such as a forklift truck or a tractor with a front loader, to lift the transport tank because of its heavy load of water and fish. The fish can stay in the transport tank at quite a high density; it is not usual to add extra oxygen into the tank during internal transport on the farm. The period that the fish can stay in the tank without a supply of oxygen is, however, limited.

The size of tank selected depends on the size of the fish to be transported. Tanks of 300–800 l are normal. Fibre glass or aluminium are the usual construction materials for transport tanks, and the design is very similar to that of tanks used for ordinary fish transport, but smaller. Tanks for internal transport may therefore be used for

transporting small amounts of fish out from the farm (external transport). The tanks are not, however, insulated like many of the long distance transport tanks. To enable the fish to be tapped out of the transport tank there may be a hatch close to the bottom which makes emptying of the tank quick and easy. The tank may also be used for vertical transport at the farm, being lifted with either a forklift truck or a tractor.

If tanks are to be used for fish transport, quite a large transport area is required. This must be as level as possible, to prevent the tractor or forklift truck tilting when lifting the tank. Use of a trans-port tank to move juvenile fish is physically undemanding. The capacity of this internal transport method depends on the size of the tank, the fish density and the duration. Fish density is species related; for example, over 500 kg in 1000 l of water can, easily result in lack of oxygen. Transport with such high densities must therefore only last for a short period of time.

Horizontal transport between units

Pipes are commonly used for internal transport of fish. The method is also often combined with pumping, for instance in cage farming. Here the pump transports the fish vertically and the horizontal transport is done through pipes. A certain excess pressure (head) is necessary for fish trans-port in pipes. If not using a pump to create this pressure, one possibility is to create a magazine of fish and water from which the fish can be tapped by gravity; alternatively, the pipe must slope down-wards and use gravity.

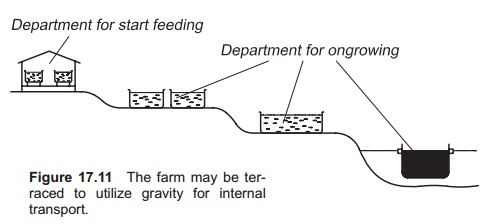

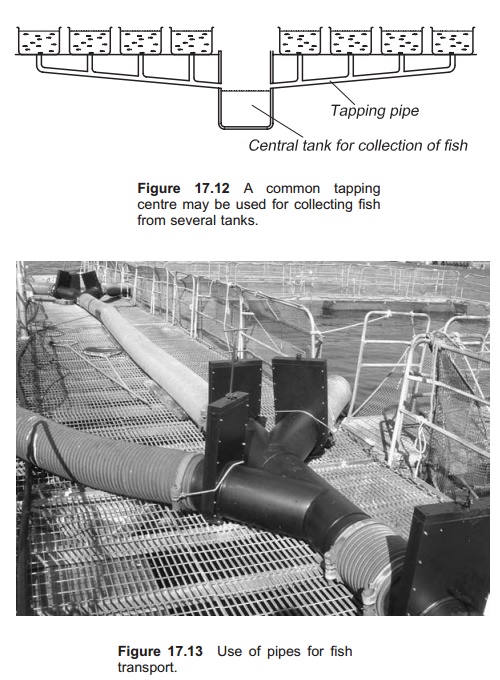

If there is a natural slope in the building area, a fish farm may be built in terraces with start feeding in the upper part and on-growing in the lower parts (Fig. 17.11). Fish transport can then be performed through pipes utilizing the natural slope. Another method is to use a common tapping centre to which tapping pipes from the fish tanks are connected. This can either be a common tapping pipe system, or there can be individual pipes from the separate tanks. From the tapping centre, vertical transport can be performed by some of the methods mentioned previously, a fish pump or a fish screw, for example. It must be possible to reduce the water level in the tapping centre to crowd the fish before vertical transport (Fig. 17.12); this can, for instance, be used to transport the fish back to other tanks or to a grader.

The same principle may also be applied in ponds, where the fish are tapped out to the harvesting tank. This requires the pond to be constructed to allow this, with a self-tapping pipe through the pond levee.

When selecting the diameter of the tapping pipe, experiments have shown that it should be large enough to enable the fish to turn inside. A diameter of at least half a fish length is a good start, but this will of coarse also be species dependent. The flow velocity inside the pipe must be sufficiently high that the fish understand it is not possible to fight against the water flow and will only be dragged along with the water flow. If the velocity is too low the fish will fight against the water flow and be exposed to more stress. The correct velocity will, of course, depend on the species and its swimming performance; for salmonids an appropriate velocity in the pipe is three to four fish lengths per second27 (Fig. 17.13).

The capacity of the system depends on the velocity of the water, the diameter of the pipe and the size of the fish; the distribution of fish through the pipe depends on the diameter of the pipe and the size of the fish. Normally, completely water filled pipes, such as from pumps, are recommended; otherwise quite large slopes on the pipes are

necessary. If using partially filled pipes, after-flushing with additional water must be carried out to empty the pipe completely of fish. If after-flushing is started before the pipes are empty of fish a more even distribution of fish through the pipes will result. If the farm is constructed with a good system for tapping of fish there is minimal requirement for human work to operate the handling system. The capacity is large both in total and per man-hour.

One question may be raised regarding the use of a common tapping centre where pipes from several tanks are connected, because there is the possibility of transferring diseases between fish tanks through the pipes and the common tapping centre. When a farm is going to be constructed or reconstructed, much effort must be put into the disinfection systems, drainage and insulation of single tanks, when a tapping centre is to be used.

If the fish are to be tapped through pipelines, all the valves in the system must be of the ball or throttle type; with these valves the pipe diameter can be completely open through the total cross section. This is important to avoid narrowing in the pipes and by this possible damage to the fish.

Related Topics