Chapter: Aquaculture Engineering : Internal Transport and Size Grading

Methods and equipment for size grading of fish

Methods and equipment for size grading of fish

Similar to the methods and equipment for internal transport, the size grading equipment may also be divided into systems that do and do not require addition of extra energy. It may not be necessary to supply energy to the grader, but the equipment may be of a design that requires potential energy; the fish must be lifted to a higher level before grading and sent from there into the grader.

All size grading will stress the fish, even if there are variations from species to species. For this reason, it is important that the equipment used and methods employed are implemented correctly to minimize the stress response of the fish. Wounds may also occur as a result of incorrectly adjusted grading equipment. Therefore graders must be used according to the supplier’s recommendations.

Several methods are used for grading of fish. Equipment can be separated into that needing a supply of energy and equipment where the fish vol-untarily grade themselves. The first method is totally dominant. The effectiveness of the different methods is to some degree dependent on the species to be graded. The latter method is mainly used in research activities. A brief survey of the methods most used follows.

Equipment for grading that requires an energy supply

Methods where the fish are taken out of the water

Manual: Fish can, of course, be size graded manually. Each fish is taken on a table, visually graded byhand and sent to the different size classes. This method can be used to grade very small amounts of fish, but it is labour intensive. Therefore some types of automatic grader are used.

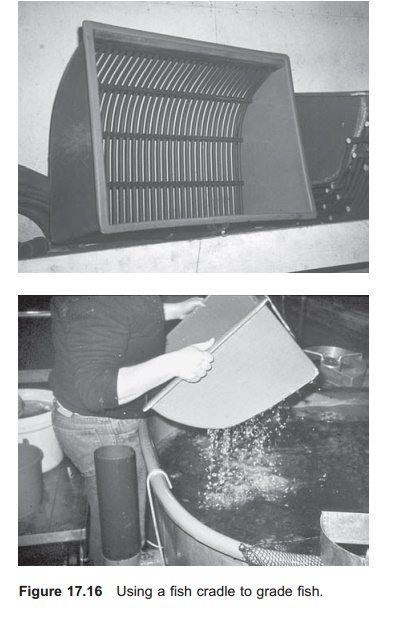

Fish cradle: A grading cradle is simple in construction and cheap to buy (Fig. 17.16). It is quite common to use a cradle, especially for the first grading, or for small species. The same is the case for smaller farms or on more extensive drift farms that seldom grade their fish. A cradle is basically a box with ribs or bars in the bottom. When using a traditional cradle, fish of different sizes are crowded einto the cradle which is placed inside the fish tank.

The cradle is then lifted up and shaken. Small fish will now fall between the ribs in the bottom of the cradle and remain in the fish tank. The cradle

containing the larger fish is then lifted out of the tank and swung into another tank where the large fish are released. In relation to capacity the use of cradle for grading is labour intensive. A cradle that is lifted manually will impose large loads on the operator’s back. The advantage with using a cradle is that it is simple, inexpensive and does not require any additional equipment.

Grading box: A grading box is based on the same principle as the grading cradle. The fish are lifted out of the fish tank, for instance using a dip net, and poured into a box with a grading grid in the bottom. The smallest fish will fall through the bottom of the grading box under gravity. The bottom consists of a grid made of bars; the distance between the bars is adjustable. The box normally slides on a rail system, and when the small fish have fallen out the box is moved over a new tank using the rail system. Here the distance between the bars in the bottom of the box is increased and fish of a new determined size then fall through the grid. Afterwards the sliding box can be moved above yet another tank and the distance between the bars increased once more, so the largest fish will fall out. The equipment has low capacity and is only recommended for grading small fish.

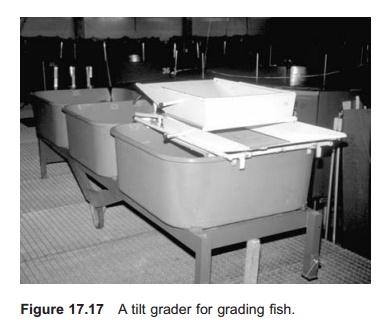

Tilt grader: A tilt grader is based on a similar principle. Fish are poured over a grid system, normally with two or more sections on top of each other (Fig. 17.17). The fish are poured into the middle section

and the smallest fish fall through all the grids and into a tank below. Then the top grading grid, which has the largest distance between the bars, is tilted to one side and the largest fish will follow and fall into a tank. Then the grader tilts the intermediate grade to the other side and the medium sized fish will fall into another tank. If a small amount of fish is being graded, the grid may be tilted manu-ally. For larger fish and larger quantities, hydraulic cylinders may be used to tilt the grids. This type of grader normally divides the fish into three size classes. It has quite low capacity and is also labour intensive.

Another method based on the same principle is also used on large fish. The fish are crowded into a grading box fixed to a sledge. When a reasonable number of fish have come into the box, hydraulic cylinders lift it. The smallest fish then fall through the grids in the bottom and down into the tank fixed below. When the sledge reaches the top of the rail system, the fish are dropped into different size groups separate from each other. In this system the vertical transport is part of the grader.

Grading grids

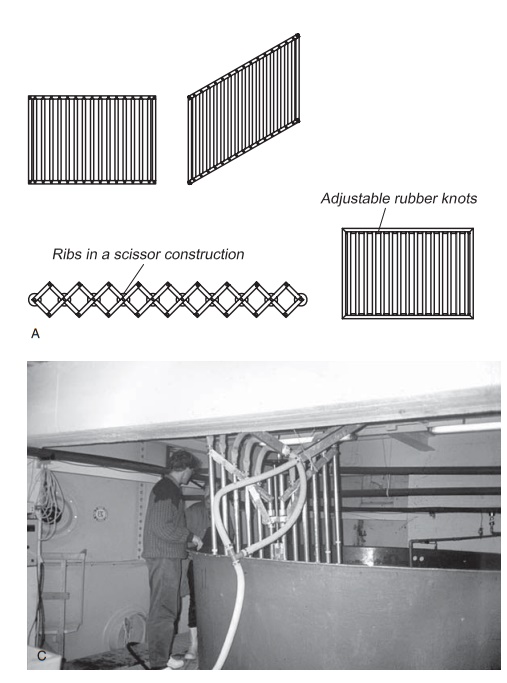

Design of a grading grid: There are a number of ways to design a grading grid, which may be placed horizontally or vertically. The grading grid can either have a fixed or variable distance between the bars. If the distance between the bars is fixed sepa-rate sizes of grading grid must be available on the farm according to the size of the fish to be graded. To achieve a variable distance between the bars several methods are available (Fig. 17.18). One method is to set the bars in a frame where the two opposite sides can be displaced parallel to each other, so changing the distance between the ribs. The scissor principle may also be used. Here the separate bars are placed in the centre of a scissor construction; by opening this out, the distance between the bars is changed. It is also possible to place removable knots of various sizes between the single bars to obtain a grading grid with variable distances between the bars, but changing the spacing between the bars will require more time.

Internal Transport and Size Grading 247 A B CFigure 17.18 Several methods are used to achieve a variable distance between the bars in a grading grid: (A) grid construction; (B, C) the grid is rotated and the smaller fish swim through while the larger fish are retained.

The same bar construction may also be used in grading grids which are to be placed vertically in the water, in a net cage, pond or sea cage. The gridmay either stay fixed in one place or dragged through the production unit as an integral part of the seine net.

Distance between the bars: The distance between the grading bars determines the size of fish to be placed in the different classes. This size, or actually the thickness of the fish, is related to its weight. It is, however, difficult to give exact values for the distances that should be used to grade out fixed sizes of fish. This of course varies with the species, because they have different body shapes. However, it also varies with the condition of the fish within the same species. A fish in good condition will be thicker than one in poor condition. Normally a fish is thickest just behind the gills, but this may vary from species to species.

To obtain a rough estimate of the distance between the bars, salmonids can be taken as an example. A rough estimate says that The width of the fish i.e. the thickness (T), is around 1/10 of the length of the fish. The condition factor of the fish (C) and the weight of the fish (W) in grams may also be used to estimate in mm (and hence the distance between the bars). The following formula may be employed:

C =(W ×100)/T 3

T = C/(W ×100)1/3

where:

T =thickness of the fish (mm)

C =condition factor of the fish

W =weight of the fish (g).

Grading machines (graders): A number of principles are used to determine the design of grading machines or grader. For all machines described the fish must be lifted out of the water; it is also necessary to lift the fish up to the grader, and the lifting height depends on the principle used for grading. Because the fish are graded in air, it is usual to spray them with water to prevent them drying out. After grading, the different fish sizes are delivered into different tanks through a pipe system, each housing a different size of fish, or the different sizes can return directly to the different fish tanks, depending on the total handling system. To get effective grading the grader must be fed continuously; the fish must not come in batches. Depending on construction, the grading machines are to various degrees adapted to take fish with different body shapes, for instance flatfish. Before choosing a grader it is therefore important to ensure that the grader is appropriate for the species.

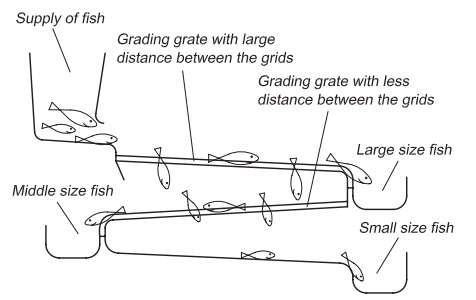

Bar graders: In a bar grader the fish slide down ona slightly sloped ‘rib table’ constructed of beams or bars (Fig. 17.19). The distance between the bars is smallest close to where the fish enter the table and then gradually increases. Therefore the smallest fish will fall through the bars first into the tank under-neath. Since the distance between the bars gradually increases larger fish will fall through when they have advanced some distance from the entry point. This type of grader is usually used to divide the fish

group into two or three size classes. The advantage with the bar grader is that there are no movable parts, but it has limited capacity compared to the other graders. What decides the capacity is the slope angle on the grading board. However, if the slope is too large sub-optimal grading will result; many fish will enter the wrong weight groups. In each case there will be an optimal slope, and this must be tested on the site.

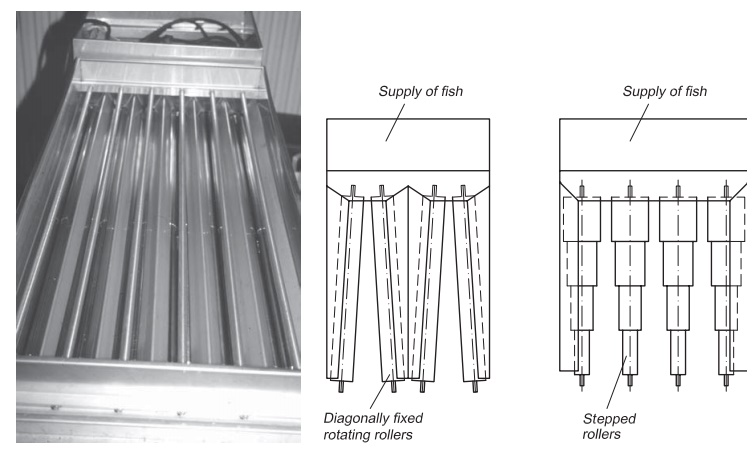

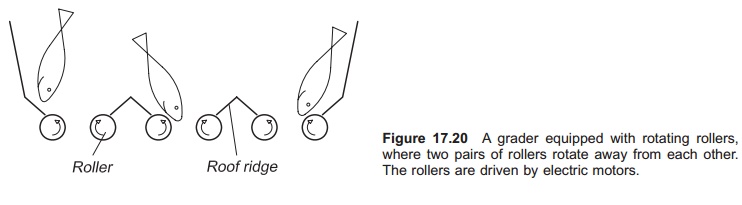

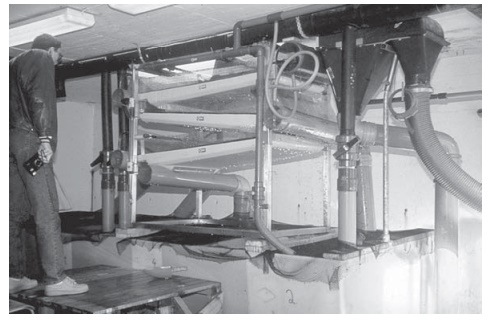

Roller grader: The design of the roller grader is similar to the bar grader, but the bars are replaced by rotating rollers. This system can be utilized for all size classes; the size of the graders is the only difference. Roller graders are normally installed on land-based farms, but may also be installed on boats or rafts for grading fish in sea cages. A machine located on a raft can be partly submerged to reduce the required lifting height.

The principle of ‘dry placed’ roller graders for juvenile and on-growing fish involves lifting and pouring the fish, so that they flow over the ‘table’ with the rotating rollers (Fig. 17.20). Two pairs of rollers rotate away from each other so that the fish are not squeezed between the rollers, but lifted up so that they fall through the grading table in the correct place. Between the pairs of rollers there is a ridge. The distance between the rollers increases from the start to the end of the grading table. Two different types of rollers are used: the first type of roller is the same diameter along the whole length and is installed with a fixed angle between the pair of rollers; in this way an increasing distance between the two rollers is achieved. The other type of roller has a diameter that decreases in steps along the direction of movement of the fish, because of which there will be an increase the distance between the rollers; this ensures separation of the fish based on thickness. A roller grader has an electric motor to drive the rollers via gear wheels. Normally this grader will divide the fish group into three to four different sizes. Roller graders have higher capacity than bar graders. The capacity depends on the number of rollers, or actually the width of the machine, the length and the slope of the rollers.

To use this type of machine, the fish must be lifted up to the grading table. The head loss over the machine is quite low (about 50 cm H2O). Normally it is therefore possible for the fish to fall directly from the machine back into ordinary fish tanks through pipelines. This type of machine is normally equipped with wheels so can be easily moved around the farm and stored when not in use.

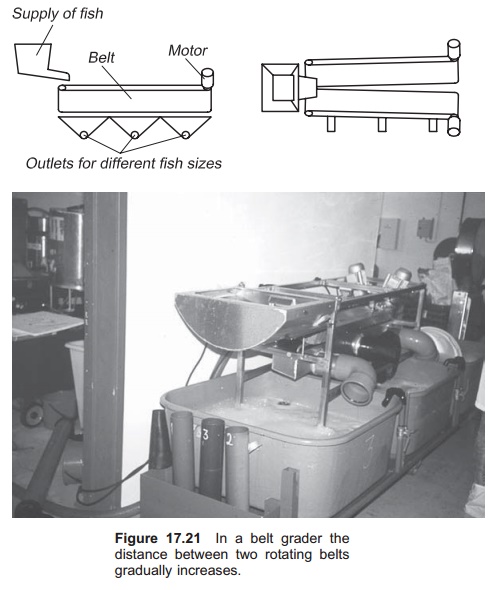

Belt grader: In a belt grader the fish slide between two rotating belts that are positioned obliquely to form a V-shaped channel with no bottom (Fig. 17.21). The rotation of the belts helps to drive the fish forward in the channel. To rotate, each belt is equipped with its own electric motor. From the point where the fish are poured into the machine, the distance between the belts gradually increases. When the distance between the belts is large

enough the fish will fall through into tanks under-neath, the smallest fish first followed by the other sizes. Normally this grader is used to grade into three size classes or more. These graders have a very low head loss, so only a low lifting height is required for the fish to enter the grader. This type of grader is also equipped with wheels for easy movement inside the farm; it is long and narrow (3–5 m) and so requires a long space.

It is important not to overload the grader with a too many fish. Sub-optimal grading will result, because the small fish may stay on top of the larger fish and in this way drop into the wrong size class. This problem may also occur with roller and beam graders, but in these cases a wider grading table can be used to increase the capacity and in this way reduce the problem.

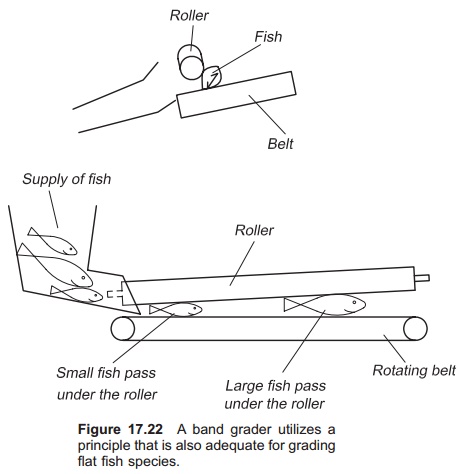

Band grader: This is a fairly new grading principle which combines the belt and the roller grader (Fig. 17.22). A tilted rotating belt or band of PVC into which the fish are lead is used. The fish lie on their side and move in the direction of rotation of the band. A roller is sited above the belt. The distance between the band and the roller gradually increases in the direction of transport. When the distance is large enough the fish will slide under the roller. In this way division into groups is achieved. It is normal to grade in groups of three sizes with this machine. The machine has also proved adequate for grading flatfish such as turbot.

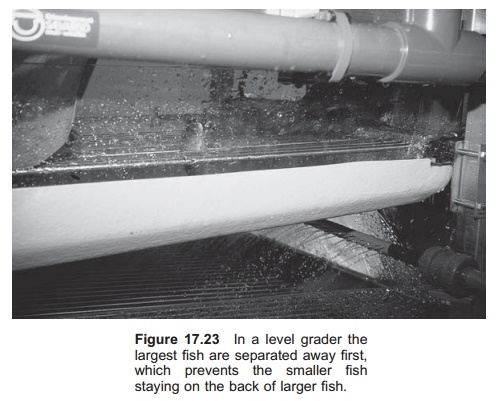

Level grader: On a level grader the fish are poured onto the top and gradually slide down through tilted grids that form a ‘grading table’ similar to the bar grader (Fig. 17.23). The larger fish will not go through the grid and will therefore be removed on the first grid. Smaller fish will continue to fall through onto a new tilted grid where the next fish size is removed, and then the same process may continue with new grids. Normally this grader will also divide fish into three size groups, but the machine may quite simply be adjusted to grade several sizes. The advantage with this machine is that there are no moveable parts and that the largest fish are removed first. The machine has a quite a high head loss and the fish must be lifted in order to enter the machine. Such graders are not normally mobile, but lightweight versions may be produced so that moving is possible. This type of machine is recommended to stay centrally placed in the farm. If the system for getting fish in and out

Other types of grader: There are also a number of other grading systems and principles that can be used. These are not described here where focus is on the most general types and basic principles. For instance, many fish farmers have constructed their own graders adapted to their specific needs.

Methods for grading the fish in the water

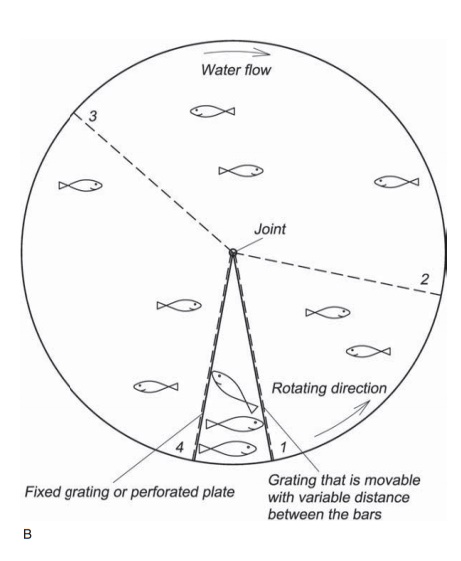

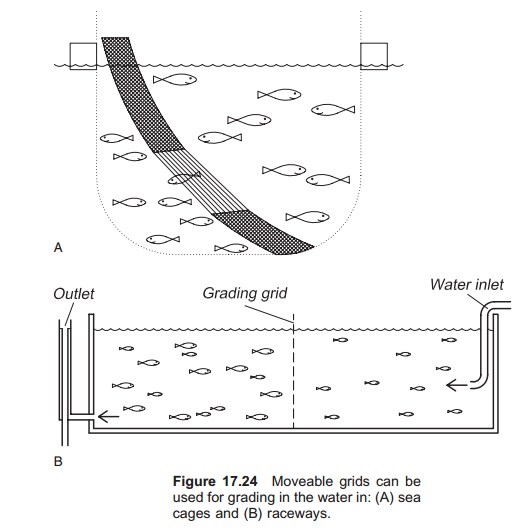

Methods where the fish are maintained in the water throughout the entire grading process have been developed for raceways, ponds, sea cages and grading channels.5,41,42 In raceways this is possible by using movable vertical grading grids (Fig. 17.24). When using the grid it is moved towards the fish which are forced to swim through. It is often used in combination with a water flow towards the fish. The smallest fish will pass through whilst the larger fish will not be able to do so and will gradually be crowded together.

Pulling two cages together and placing the grading grid in the middle gives a similar system.

Alternatively, a seine net with a grading grid included can be dragged through a cage or pond (Fig. 17.24). The smaller fish will swim through the grid and remain in the cage or pond, while the larger fish will be crowded together and can be removed. In circular tanks a similar method can be used. A vertically placed grading grid is dragged through the tank like the hand on a watch. Another dense grid is fixed in the tank. Both the grading grid and the dense grid are fixed on a fitting in the centre of the tank; this may, for instance, be a centre drain in the tank.

Methods for voluntary grading (self grading)

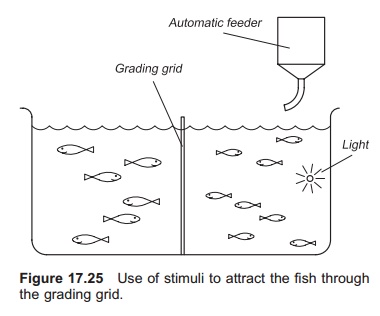

The same stimuli that are used for voluntary fish transport have been used for self grading (Fig. 17.25). Water flow towards the fish, scented sub-stances, manipulation of light conditions and behaviour training have all had some effect, but full size grading of an entire fish group has been shown

to be impossible. In addition, it is necessary to have a slightly larger distance between the ribs when using stimuli compared to traditional methods for grading because the fish will not go through small passages voluntarily. In particular, when the fish feel the ribs on their sides they will stop swimming voluntarily. In practice, where time is limited, stimuli are not useful for voluntary grading of fish.

Related Topics