Chapter: Physics : Magnetic Materials

Magnetic Materials

Magnetic Materials

1

Introduction

1.1

Basic Definitions

2

Origin of Magnetic Moments

3

Classification of Magnetic Materials

3.1

Diamagnetic materials

3.2

Paramagnetic Materials

3.3

Ferromagnetic materials

3.4

Dia, Para and Ferro magnetic materials – Comparison

4

Domain Theory of Ferromagnetism

4.1

Energies involved in the domain growth (or) Origin of Domain theory of

Ferromagnetism

5

Antiferromagnetic Materials

6

Ferrimagnetic Materials

7

Hysteresis

7.1

Explanation of hysteresis on the basis of Domains

8

Hard and Soft Magentic Material

8.1

Hard Magnetic Materials

8.2

Soft Magnetic Materials

8.3

Difference between Hard and Soft magnetic materials

9

Ferrites

9.1

Properties

9.2

Structures of Ferrites

9.3

Regular spinal

9.4

Inverse spinal

9.5

Types of interaction present in the ferrites

9.6

Properties of ferromagnetic materials

9.7

Application of Ferrites

10

Magnetic Recording and Readout Memory

10.1

Magnetic parameters for Recording

10.2

Storage of Magnetic Data

10.3

Magnetic Tape

10.4

Magnetic Disc Drivers

10.5

Floppy Disk

10.6

Magnetic bubble Materials

1 INTRODUCTION

The

materials which can be made to behave like a magnet and which are easily

magnetic field called as a magnetic materials.

1.1 Basic Definitions

1. Magnetic Dipole Moment (M)

The

dipole moment is defined as the product of magnetic pole strength and length of

the magnet. It is given by M = ml. Amp m2.

2. Magnetic Field

The space

around which the magnetic lines of forces exist is called as magnetic field.

Magnetic field is produced by permanent magnets such as a horse shoe magnet and

temporarily by elelctromagnets (or) superconducting magnets.

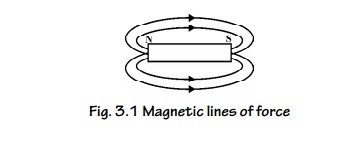

3. Magnetic Lines of Force

The

continuous curve in a magnetic field that exists from north pole to south pole

is called as magnetic lines of force.

Fig. 3.1

Magnetic lines of force

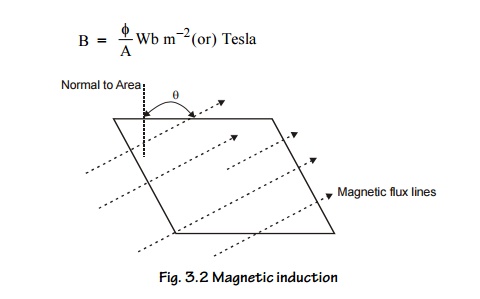

4. Magnetic Induction (B) (or) Magnetic Flux

Density

It is the

number of magnetic lines of force passing through unit area of cross section.

5. Magnetic Field Strength (or) Magnetizing Field

(H)

It is the

force experienced by a unit north pole placed at a given point in a magnetic

field. The magnetic induction B due to the magnetic field of intensity H

applied

in vacuum is related by B =μ 0H Amp m–1.

6. Magnetic Flux (ϕ )

The total

number of magnetic lines of force passing through a surface.

Unit : Weber.

7. Intensity of Magnetization (I)

Magnetization

is the process of converting a non-magnetic material in to a magnetic material.

It is

also defined as the magnetic moment per unit volume. I = m / V web m–2.

8. Magnetic Permeability (μ )

It is ratio of the magnetic induction (B) to the applied magnetic field intensity (H). μ= B / H

Unit: Henry m–1

It is the

measure of ability of the material to permit magnetic lines of force.

9. Relative Permeability ( μr)

It is

defined as the ratio of permeability of the medium to the permeability of the

free space

10. Magnetic Susceptibility χ

It is defined as the ratio of intensity of magnetization (I) and intensity of magnetic field (H). χ= I / H.

The sign and magnitude of χ are used to

determine the nature of the magnetic materials.

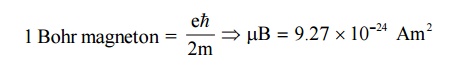

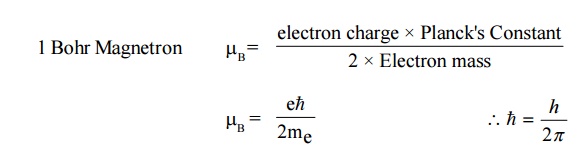

11. Bohr Magnetron ( μB)

The

orbital magnetic moment and the spin magnetic moment of an electron in an atom

can be expressed in terms of atomic unit of magnetic moment called as Bohr

magnetron.

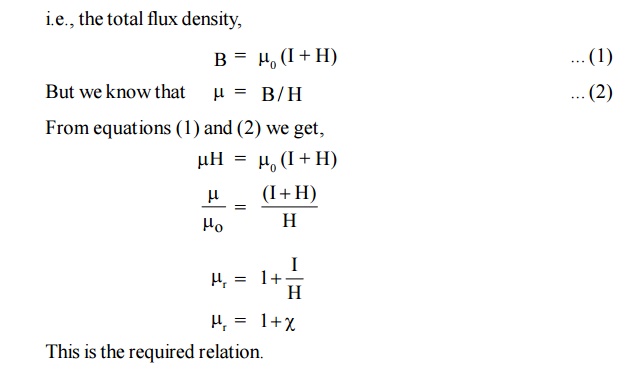

12. Relation between susceptibility (χ ) and Relative permeability ( μr)

We know

that when a current is supplied through a coil, magnetic field is developed.

When a magnetic material is placed inside a external magnetic field, the

magnetic flux density (B) arises due to applied magnetic field (H) and also due

to the induced magnetization (I).

i.e., the

total flux density,

13. Retentivity or Remanence

When an

external field is applied to the specimen it is magnetized and when the field

is removed it is demagnetized. But some materials do not completely demagnetize

when field is removed. There is some magnetism left out in the specimen. “This

residual magnetism which is left out even after the removal of the external

magnetic field” is called as the Retentivity or Remanence.

14. Coercivity

The

residual magnetism can be removed completely from the material by applying a

reverse magnetic field. “The reverse magnetic field which is used to completely

remove the residual magnetism” is called as the coercivity.

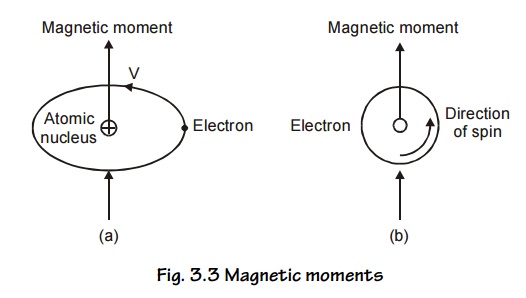

2 ORIGIN OF MAGNETIC MOMENTS

The

macroscopic magnetic properties of a substance are a consequence of magnetic

moments associated with individual electrons. Each electron in an atom has

magnetic moments that originate from the following two sources

Orbital magnetic moment of electrons

Spin magnetic moment of electrons.

Magnetic

moments associated with an orbiting electron and a spinning electron is shown

in Fig.3.3 (a and b).

We know

that the electrons in an atom revolve around the nucleus in different orbits.

Basically, there are three contributions for the magnetic dipole moment of an

atom.

The

orbital motion of electrons (the motion of electrons in the closed orbits

around the nucleus). It is called as orbital magnetic moment. Its magnitude is

always small. Spin motion of the electrons (i.e. due to electron spin angular

momentum) and it is called as spin magnetic moment.

The

contribution from the nuclear spin (i.e., due to nuclear spin angular

momentum). Since this is nearly 103 times smaller than that of

electron spin, it is not taken into consideration.

For all

practical purposes, we assume that the magnetic moment arises due to the

electron spin ignoring the orbital magnetic moments and the nuclear magnetic

moments as their magnitudes are small.

We may

note that permanent magnetic moments can also arise from spin magnetic moments

of the nucleus. Of all the three, the spin dipole moments of electrons are

important in most magnetic materials.

1. Orbital angular momentum

This

corresponds to permanent magnetic dipole moments. Let us consider an electron

describing a circular orbit of radius ‘r’ with a stationary nucleus at the

centre as shown in Fig 3.3.(a). Let the electron rotate with a constant angular

velocity of ‘w’ radians per second.

Electron

revolving in any orbit may be considered as current carrying circular coil

producing magnetic field perpendicular to its plane. Thus the electronic orbits

are associated with a magnetic moment. The orbital magnetic moment of an

electron in an atom can be expressed in terms of atomic unit of magnetic moment

called Bohr Magnetron, defined as

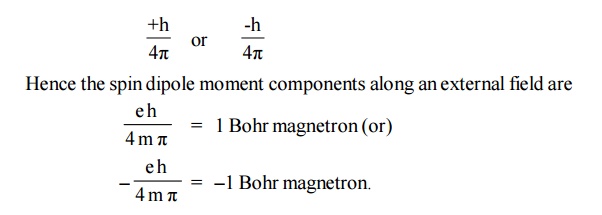

2. Electron spin magnetic moment

The

concept of the electron having an angular momentum has been introduced in order

to explain the details of atomic spectra. This angular momentum of the electron

is referred to as the spin of the electron. Since the e- has a

charge, its spin produces a magnetic dipole moment.

According

to quantum theory, the spin angular momentum along a given direction is

In a many

electron atom, the individual spin magnetic moments are added in accordance

with certain rules. Completely filled shells contribute nothing to the

resultant spin moment.

3. Nuclear magnetic moment

The

angular momentum associated with the nuclear spin is also measured in units of

h/2π . The mass of the nucleus is larger than that of an e- by the

order of 103. Hence nuclear spin magnetic moment is of the order of

10–3 Bohr magnetrons.

3 CLASSIFICATION OF MAGNETIC MATERIALS

The

magnetic materials are classified into two categories:

The materials without permanent magnetic moment Example:

1. Diamagnetic materials.

The materials with permanent magnetic moment. Example:

1. Paramagnetic materials

Ferromagnetic materials

Anti-Ferromagnetic materials

Ferrimagnetic materials.

3.1 Diamagnetic materials

Definition

In a

diamagnetic material the electron orbits are randomly oriented and the orbital

magnetic moments get cancelled. Similarly, all the spin moments are paired

i.e., having even number of electrons. Therefore, the electrons are spinning in

two opposite directions and hence the net magnetic moment is zero.

Effect of magnetic field

When an

external magnetic field is applied, the electrons re-orient and align

perpendicular to the applied field, i.e., their magnetic moment opposes the

external magnetic field.

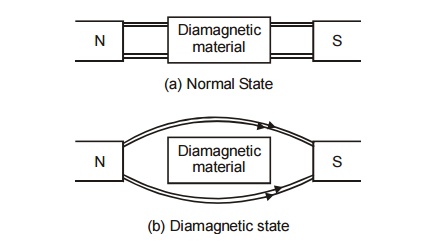

Fig.

3.4 Effect of magnetic field in Diamagnetic material

In the

above diagram, there is no penetration of magnetic lines through the

diamagnetic material.

Properties

They repel the magnetic lines of force, if placed

in a magnetic field as shown in figure (3.4).

The susceptibility is negative and it is

independent to temperature and applied field strength. (X = –ve)

The permeability is less than one

There is no permanent dipole moment.

When the temperature is greater than the critical

temperature diamagnetic becomes normal material.

It has superconducting property.

Examples

: Gold, germanium, silicon, antimony, bismuth, silver, lead, copper, hydrogen,

Water and alcohol.

3.2 Paramagnetic

Materials

Definition

Para magnetism

is due to the presence of few unpaired electrons which gives rise to the spin

magnetic moment. In the absence of external magnetic field, the magnetic

moments (dipoles) are randomly oriented and possess very less magnetization in

it.

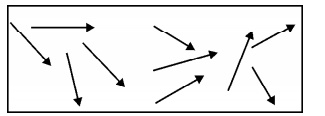

Fig.3.5

Paramagnetic Material

Effect of magnetic field

When an

external magnetic field is applied to paramagnetic material, the magnetic

moments align themselves along the field direction and the material is said to

be magnetized. This effect is known as paramagnetism.

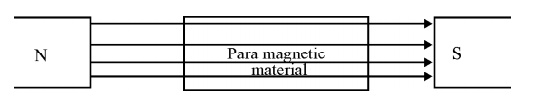

Fig.

3.6 Effect of magnetic field in paramagnetic material

Thermal

agitation disturbs the alignment of the magnetic moments with an increase in

temperature, the increase in thermal agitation tends to randomize the dipole

direction thus leading to decrease in magnetization.

This

implies that the paramagnetic susceptibility decreases with increase in

temperature. It is observed that the paramagnetic susceptibility varies

inversely with temperature.

There is a permanent magnetic moment.

When the temperature is less than the Curie

temperature, paramagnetic materials become diamagnetic materials.

It spin alignment is random in nature.

Examples

: Platinum, CuSO 4 , MnSO4 , Aluminum, etc

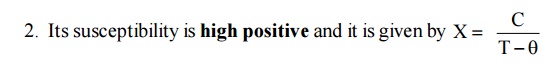

3.3 Ferromagnetic materials

Definition

Ferromagnetism

is due to the presence of more unpaired electrons. Even in the absence of

external field, the magnetic moments align parallel to each other. So that it

has large magnetism. This is called spontaneous magnetization.

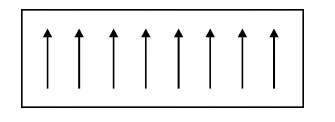

Fig. 3.7

Ferromagnetic materials

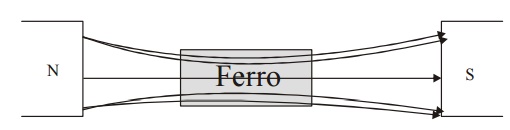

Effect of magnetic field

If a

small external magnetic field is applied the magnetic moments align in the

field direction and become very strong magnets.

Fig.3.8

Effect of magnetic field in ferromagnetic material

Properties of ferromagnetic materials

1. All

the magnetic lines of force pass through the material.

The permeability is very much greater than one.

They have enormous permanent dipole moment.

When the temperature is greater than the Curie

temperature, the Ferromagnetic material becomes paramagnetic material.

The ferromagnetic material has equal magnitude

dipole lying parallel to each other.

Examples:

Nickel,

iron, Cobalt, Steel, etc.

(Curie

temperature - The temperature below which a material can acts as

ferromagnetic material and above which it can acts as paramagnetic material is

called Curie temperature.)

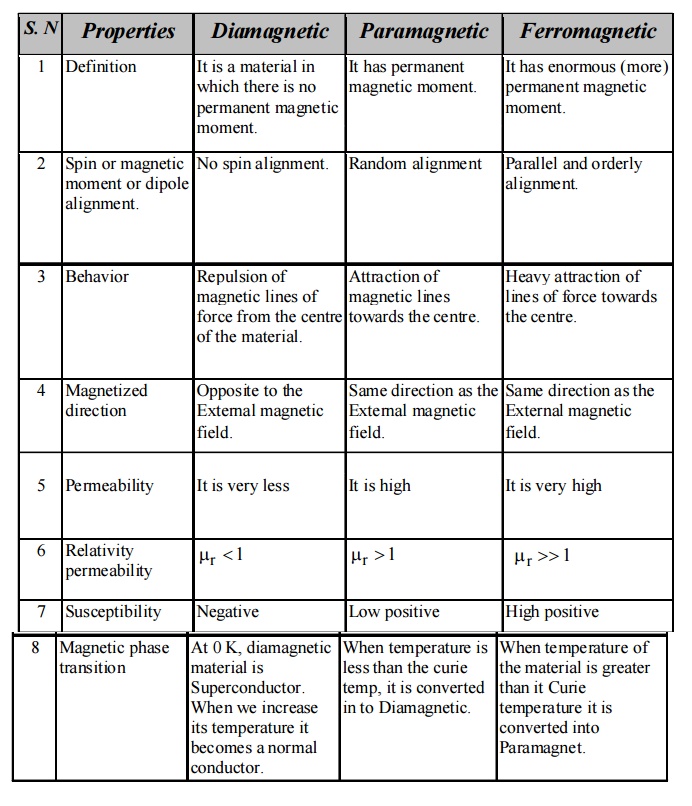

3.4 Dia, Para and Ferro magnetic materials –

Comparison

4 DOMAIN THEORY OF FERROMAGNETISM

This

theory was proposed by Weiss in 1907. It explains the hysteresis and the

properties of ferromagnetic materials.

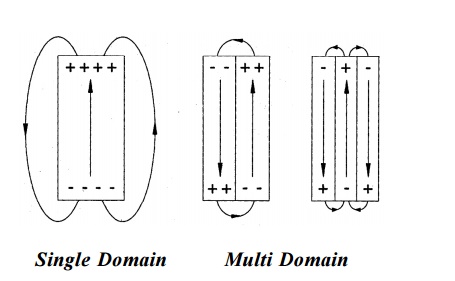

Magnetic Domains

A

ferromagnetic material is divided into a large number of small region is called

domains. (0.1 to 1 of area), each direction is spontaneously magnetized. The

direction of magnetization varies from domain to domain and the net

magnetization is zero, in the absence external magnetic field. The boundary

line which separates two domains is called domain wall or Block wall. When the

magnetic field is applied to the Ferromagnetic material, the magnetization is

produced by two ways.

By the motion of domain walls.

By the rotation of domains.

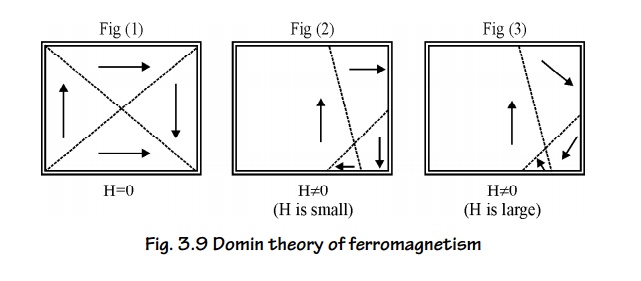

Process of Domain magnetization

There are

two ways to align a random domain structure by applying an external magnetic

field.

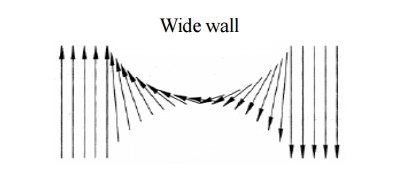

1. By the motion of Domain walls

When a

small amount of magnetic field is applied, the domains having dipoles parallel

to the applied magnetic field increases in area by the motion of domain walls.

(Fig. 3.9 (2)).

2. By the rotation of Domains

If the

applied magnetic field is further increased, the domains are rotated parallel

to the field direction by the rotation of domains. (fig. 3.9 (3)).

Fig. 3.9

Domin theory of ferromagnetism

Energies involved in the domain growth (or)

Origin of Domain theory of Ferromagnetism

We can

understand the origin of domains from the thermodynamic principle i.e., in

equilibrium, the total energy of the system is minimum.

The total

internal energy of the domain structure in a ferromagnetic material is made up

from the following contributions.

Exchange energy (or) Magnetic field energy.

Crystalline energy (or) Anisotropy energy.

Domain wall energy (or) Bloch wall energy.

Magnetostriction energy

Exchange

energy (or) Magnetic Field energy

“The

interaction energy which makes the adjacent dipoles align themselves” is the

called exchange energy (or) magnetic

field energy.

The

interaction energy makes the adjacent dipoles align themselves. It arises from

interaction of electron spins. It depends upon the inter atomic distance. This

exchange energy also called magnetic field energy is the energy required in

assembling the atomic magnets into a single domain and this work done is stored

as potential energy. The size of the domains for a particular domain structure

may be obtained from the principle of minimum energy. The volume of the domain

may very between say, say, 10–2 to 10–6 cm3.

Fig. 3.10

Exchange energy in ferromagnetism

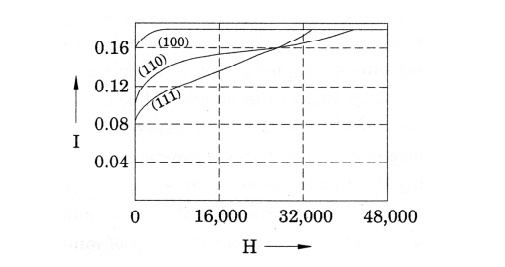

2. Anisotropy energy

The

excess energy required to magnetize a specimen in particular direction over

that required to magnetize it along the easy direction is called the crystalline anisotropy

energy.

In

ferromagnetic materials there are two types of directions of magnetization

namely,

Easy direction and

hard directions.

In easy

direction of magnetization, weak field can be applied and in hard direction of

magnetization, strong field should be applied.

Crystalline

anisotropy energy is energy of magnetization which is the function of

crystal orientation. As shown in figure magnetization curves for iron with the

applied field along different crystallographic direction crystallographic

directions have been drawn. For example, in BCC iron the easy direction is

[100], the medium direction is [110], and the hard direction [111]. The energy

difference between hard and easy direction to magnetize the material is about.

This energy is very important in determining the characteristic domain

boundaries.

Fig.

3.11 Anisotropy energy in ferromagnetism

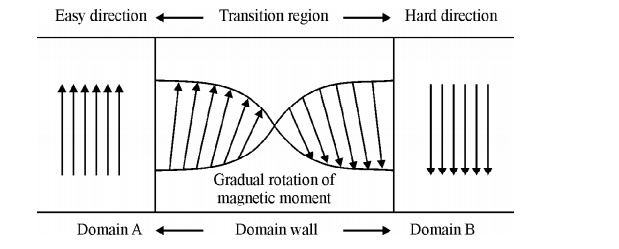

3. Domain wall energy or Bloch wall energy

A thin

boundary or region that separates adjacent domains magnetized in different

directions is called domain wall or Bloch wall.

Fig.

3.12 The change of electron spin in the transition region of Bloch wall

The size

of the Bloch walls is about 200 to 300 lattice constant thickness. In going

from one domain to another domain, the electron spin changes gradually as shown

in figure. The energy of domain wall is due to both exchange energy and

anisotropic energy.

Based on

the spin alignments, two types of Bloch walls may arise, namely

Thick wall: When the spins at the boundary

are misaligned and if the direction of

the spin changes gradually as shown

figure, it leads to a thick Bloch wall. Here the misalignments of spins are

associated with exchange energy.

Fig.

3.13 The change of electron spin in the transition region of thick wall

Thin wall: When the spins at the boundaries changes abruptly, then the anisotropic energy becomes very less.

Since the anisotropic energy is directly proportional to the thickness of the

wall, this leads to a thin Bloch wall.

Fig.3.14

The change of electron spin in the transition region of thin wall

4. Magnetostriction energy

When a

material is magnetized, it is found that it suffers a change in dimensions.

This phenomenon is known as Magnetostriction.

This deformation is different along different crystal directions. So if the

domains are magnetized in different directions, they will either expand or

shrink. This means that work must be done against the elastic restoring forces.

The work done by the magnetic field against these elastic restoring forces is

called magneto-elastic energy or Magnetostrictive energy.

5 ANTIFERROMAGNETIC

MATERIALS

Definition

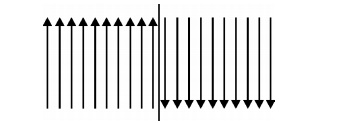

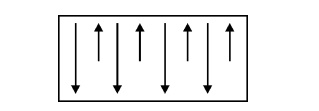

In this

material, the spins are aligned in anti-parallel manner due to unfavorable exchange

interaction among them, resulting in zero magnetic moment. Even when the

magnetic field is increased, it has almost zero induced magnetic moment.

Fig.

3.15 Spin alignment of antiferromagnetic materials

Properties

1. It susceptibility

is very small and it is positive.

Examples

: Ferrous oxide, Fe Cl4 ,Mn O4 ,MnS

and some ionic compounds etc.

6 FERRIMAGNETIC MATERIALS

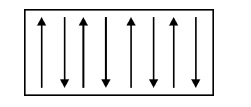

Definition

Ferrimagnetic

materials or Ferrites are much similar to Ferromagnetic materials. The magnetic

dipoles are aligned anti-parallel with unequal magnitudes. If small value of

magnetic field is applied, it will produce the large value of magnetization.

Ferrimagnetic

materials are widely used in high frequency applications and computer memories.

Fig.

3.16 Spin alignment of Ferrimagnetic materials

Properties

These materials have low eddy current loss and low

hysteresis losses.

Examples:

Ferrous

Ferrites and Nickel Ferrites

7 HYSTERESIS

Hysteresis

means “Lagging” i.e., The Lagging of intensity of magnetization (I) behind the

intensity of magnetic field (H).

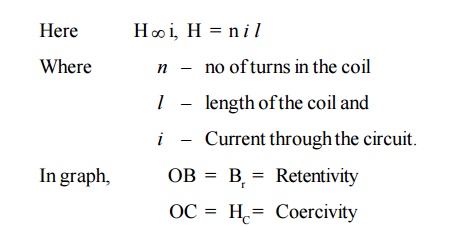

Experimental Determination

A graph

is drawn between the intensity of

magnetization [I] and the intensity

of magnetic field [H], for a cycle

of magnetization. The experimental setup consists of solenoid coil through which current is passed and the material

is magnetized. By varying the value of current we can get different values of

Intensity of magnetization [I] due to the magnetic field (H) in the solenoid.

When the

intensity of magnetic field ‘H’ is increased from O to F, the value of

Intensity of magnetization T if also increases from O to A, at ‘A’ the material

reaches the saturation value of Intensity of magnetization.

Then the

value of I is constant.

When intensity of magnetic field ‘H’ is decreased

from G to O, the value of Intensity of magnetization ‘I’ also decreases from A

to B, but not to zero (0). Now the material retains [stores] some amount of

magnetism known as Retentivity, even

though the intensity of magnetic field ‘H’ is zero. It is represented as ‘OB’ in the graph.

When intensity of magnetic field ‘H’ is increased

in reverse direction from O to C, the value of Intensity of magnetization ‘I’

decreases from B to C. i.e., the value of ‘I’ reaches zero.

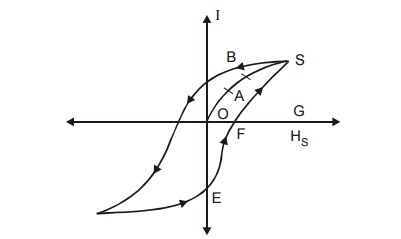

Fig.3.17

Hysteresis curve

The amount of intensity of magnetic field ‘H’

applied in the reverse direction to remove the retentivity is known as Coercivity

or Coercive force. It is represented as ‘OC’ in the graph.

Further repeating the process the remaining portion

[CDEFA] in the graph is obtained. The closed loop [OABCDEFA] is called

Hysteresis loop (or) (I – H) curve. For one cycle of magnetization.

Now the material is taken out. After a cycle of

magnetization, there is some expenditure (loss) of energy.

This loss of energy is radiated in the form of heat

energy in the material.

This loss of energy is directly proportional to the

area of the loop.

From the

Hysteresis graph, we can select soft and hard magnetic materials depending upon

the purpose.

Energy product

It is the

product of residual magnetism Br and coercivity which HC

gives the maximum amount of energy stored in the specimen.

Energy

product = Br × HC

Hysteresis loss

When the

specimen is taken through a cycle of magnetization. There is a loss of energy

in the form of heat. This loss of energy is known as Hysteresis loss.

7.1 Explanation of hysteresis on the basis of

Domains

Fig.3.18

Hysteresis curve on the basis domain theory

OA - Due

to smaller reversible domains wall movement.

AB - Due

to larger irreversible domain wall movement.

BS - Due

to smaller irreversible domain rotation.

S -

Point of saturation.

When a

field is applied, for small H, the domain walls are displaced and gives rise to

small value of magnetization. [OA in the graph]. Now, the field is removed, the

domains return to its original state known as reversible domains.

When the

field is increases, a large number of domains contribute to the magnetization

and I increases rapidly with H.

Now, when

the field is removed the domain boundaries do not come back to the original

position due to the domain wall movement to a very large distance (AB in the

graph). These domains are called irreversible domains.

Now if

the field is further increased, domains start rotating along the field

direction and anisotropic energy is stored and it is represented as BC in the

graph.

Thus the

specimen is said to attain maximum magnetization at this position even after

the removal of the field. The material is having magnetism called Retentivity.

This Retentivity can be destroyed by applying a high reverse magnetic field

called coercivity.

Thus the

reversible and irreversible domain wall movements give rise to hysteresis in

the Ferromagnetic materials.

8 HARD AND

SOFT MAGENTIC MATERIAL

In

Hysteresis, after a cycle of magnetization, there is some expenditure (loss) of

energy. This loss of energy is radiated in the form of heat energy in the

material and it is directly proportional to the area of the loop. From the

Hysteresis graph, we can select the soft and hard magnetic materials.

8.1 Hard Magnetic Materials

The materials which are very difficult to magnetize

and demagnetize are called hard magnetic materials. These

materials can be made by heating the magnetic

materials and then cooling it suddenly.

It can also be prepared by adding impurities.

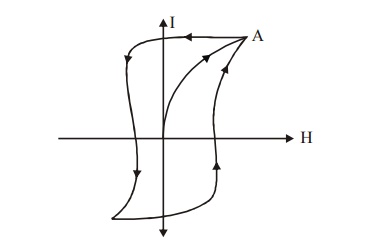

Fig.3.19

Hysteresis loop of a hard magnetic material

The above

hysteresis loop is very hard and has a large loop area for a hard magnetic

material, therefore the loss is also large. Domain wall does not move easily

and require large value of H for magnetization. Its coercivity and retentivity

values are large. Its eddy current loss is also high due to its low

resistivity, the magnetostatic energy is large. It has low susceptibility and

permeability. The hard magnetic materials have large amount of impurities and

lattice defects.

Examples

: Tungsten steel, Carbon steel,

Chromium steel, Alnico etc.,

Properties

It is easilly magnetised and demagnetised.

They hysteresis area is very small and hence, the

hysteresis loss is also small, as shown in figure.

The coercivity and rentenivity are very small.

These materials have large values of susceptibility

and permeabilty.

Their magnetostatic energy is very small.

The eddy current loss is very small.

Applications

Iron-Silicon alloys are used in electrical

equipment and magnetic cores of transformes.

Cast iron is used in the structure of electical

machinery and the frame work of D.C machine.

Nickel alloys are used to manufacture inductors,

relays and small motors.

It is also used for computer and data storage

devices.

8.2 Soft Magnetic Materials

The materials which are easily magnetized and

demagnetized are called soft magnetic materials. These

materials can be made by heating the

magnetic materials and then cooling

it slowly to attain an ordered

structure of atoms.

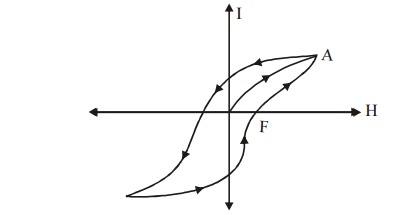

Fig.3.20

Hysteresis loop of a soft magnetic material

The above

hysteresis loop is very small and has a less loop area for a soft magnetic

materials. Therefore the loss is also small. Domain wall move easily and

require small value of H for magnetization. Its coercivity and retentivity

values are small, its eddy current loss is small due to its high resistivity.

The magnetostatic energy is less, it has high value of susceptibility and

permeability. The soft magnetic materials do not have impurities and lattice

defects.

Examples:

Iron-Silicon alloys, Nickel-Iron

alloys and Iron-cobalt alloys.

Properties

It is very hard to magnetize and also demagnetize.

The hysteresis cure is very broad and has a large

as shown in figure.

The coercivity and retentivity values are large.

These materials have low value of susceptibility

and permeability.

The magnetostatic energy is large.

The eddy current loss is very high.

Applications

Magnets made by carbon steel are used for

manufacturing the toys and compass needle.

Tungsten steel is used in making permanent magnets

for D.C motors.

It is also used for making a small size of magnets.

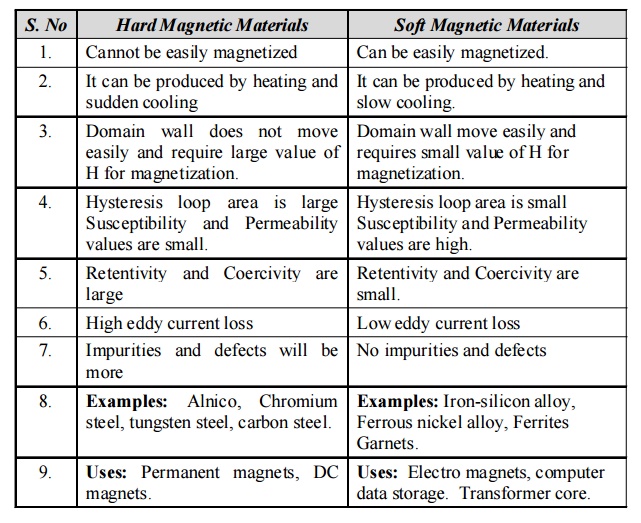

8.3 Difference between Hard and Soft magnetic

materials

Hard Magnetic Materials

1. Cannot

be easily magnetized

2. It can

be produced by heating and sudden cooling

3. Domain

wall does not move easily and require large value of H for magnetization.

4.

Hysteresis loop area is large Susceptibility and Permeability values are small.

5.

Retentivity and Coercivity are large

6. High

eddy current loss

7.

Impurities and defects will be more

8.

Examples: Alnico, Chromium steel, tungsten steel, carbon steel.

9. Uses:

Permanent magnets, DC magnets.

Soft Magnetic Materials

1. Can be

easily magnetized.

2. It can

be produced by heating and slow cooling.

3. Domain

wall move easily and requires small value of H for magnetization.

4.

Hysteresis loop area is small Susceptibility and Permeability values are high.

5.

Retentivity and Coercivity are small.

6. Low

eddy current loss

7. No

impurities and defects

8.

Examples: Iron-silicon alloy, Ferrous nickel alloy, Ferrites Garnets.

9. Uses:

Electro magnets, computer data storage. Transformer core.

9 FERRITES

Definition

Ferrites

or Ferrimagnetic materials are the modified structure of iron without carbon.

In Ferities the spins of adjacent ion is the presence of a magnetic field are

in opposite directions with different magnitudes.

9.1 Properties

These are made from ceramic ferromagnetic compounds.

It has low tensile strength and it is brittle and

soft.

In these materials all valence electrons are tied

up by ionic bonding.

These are bad conductors with high resistivity of

the order of 1011 m

Ferrites have low eddy current loss and low hysteresis

loss.

The general formula for Ferrites is X²+

(Fe2)3+ O4 where X-may is a metal (divalent

metal) such as Mg, Ni, Mn, Zn, etc.

Ferrites are manufactured by powder metallurgical

process by mixing, compacting and then sintering at high temperatures followed

by age hardening in magnetic fields.

9.2 Structures

of Ferrites

Ferrites

are the magnetic compounds consisting to two or more different kinds of atoms.

Generally ferrites are expressed as X²+ (Fe2)3+ O 4 where

X²+ stands for suitable divalent metals ions such etc Mg2+,

Zn2+, Fe2+, Mn2+, Ni2+ etc.

Normally,

there are two types of structures present in the ferrites

1.

Regular spinel 2. Inverse spinel

9.3

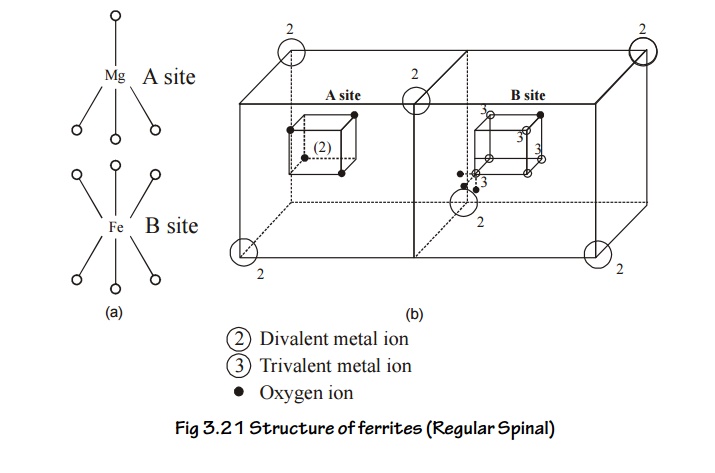

Regular spinal

In the

regular spinal type, each metal atom (divalent) is surrounded by fourions in a

tetragonal fashion.

For

example in Mg2+, Fe23+, O42+,

the structure of Mg2+is given in the Fig. 3.21 and it is called “A’

site. Totally in a unit cell, there will be 8 tetrahedral (8A) sites.

Each Fe3+

(trivalent) is surrounded by ‘6’ O2 ions and forms an

octahedral fashion as show in Fig.3.20. Totally there will be 16 such

octahedral sites in the unit cell. This in indicated by ‘B’ site.

Thus in a

regular spinal, each divalent metal ion (mg2+) exists in a

tetrahedral form (A site) and each trivalent metal ion (Fe2+) exists

in an octahedral form (B site). Hence, the sites A and B combine together to

form a regular spinal ferrite structure as shown in Fig.3.21.

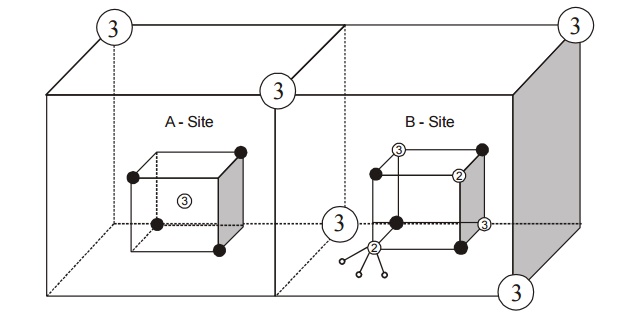

9.4

Inverse spinal

In this

type, we consider the arrangement of dipoles of a single ferrous ferrite

molecule Fe3+ [Fe2+ Fe3+] O42–

Fe3+ , ions (trivalent) occupies all A sites (tetrahedral) and half

of the B sites (octahedral) also.

Thus the

left out B sites will be occupied by the divalent (Fe2+). The

inverse spinal structure is shown in the Fig. 3.22.

Fig.3.22

Structure of ferrites (inverse Spinal)

9.5 Types of interaction present in the ferrites

The spin

arrangement between the A site B site is in an ant parallel manner and it was

explained by Neel. According to him, in ferrites, the spin arrangement is ant

parallel and there exists some interaction between the A and B sites which is

represented as AB interaction.

Apart

from this, there are two more interactions (i.e.,) AA and BB interaction which

is negative and considerable weaker than AB interaction.

The

tendency of AB interaction is to align all A spins parallel to each other and

anti parallel to all B spins, but the tendency of AA and BB interaction is to

spoil the parallel arrangement of AB spins respectively.

Since AB

is very strong as compared with AA and BB, the effect of AB interaction

dominates and gives rise to anti parallel spin arrangement.

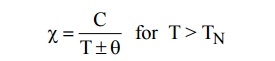

9.6 Properties

of ferromagnetic materials

Ferromagnetic materials posses’ net magnetic

moment.

Above Curie temperature, it becomes paramagnetic

while it behaves as ferromagnetic material below Curie temperature.

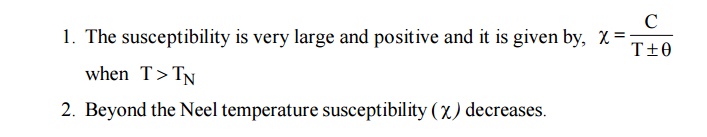

The susceptibility of Ferrimagnetic material is

very large and positive. It is temperature dependent and is given by

Beyond Neel temperature,decreases.

Spin alignment is anti parallel of different

magnitudes.

Mechanically, it has pure ion character.

They have high permeability and high resistivity.

They have low eddy current losses and low

hysteresis.

9.7 Application

of Ferrites

Ferrites are used to produce ultrasonic wave by

Magnetostriction principle.

Ferrites are used in audio and video transformers.

Ferrites rods are used in radio receivers to

increase the sensitivity.

Ferrites

are widely used in non-reciprocal microwave devices such as gyrator, circulator

and Isolator.

Gyrator : It transmits the power freely in both

directions with a phase shift of radians.

Circulator : It

provides sequential transmission of power between the ports.

Isolator : It is used to display differential

attenuation.

They are also used for power limiting and harmonic

generation.

Ferrites are used in parametric amplifiers so that

the input can be amplified with low noise.

They are used in computers and data processing

circuits.

Bi-stable elements, Ferro cube (Ferrite with square

hysteresis loop), magnetic shift register, and magnetic bubbles are also

examples for Ferrites.

10 MAGNETIC

RECORDING AND READOUT MEMORY

Nowadays,

large number of information are stored in (or) retrieved from the storage

devices, by using devices is magnetic recording heads and they function

according to the principle of magnetic induction.

Generally

Ferro or Ferrimagnetic materials are used in the storage devices because in

this type of materials only the magnetic interaction between only two dipoles

align themselves parallel to each other.

Due to

this parallel alignment even if we apply small amount of magnetic field, a

large value of magnetization is produced. By using this property information

are stored in storage devices.

In the

storage devices, the recording of digital data (0’s and 1’s) depends upon the

direction of magnetization in the medium.

10.1

Magnetic parameters for Recording

When current is passed through a coil, a magnetic

field is induced. This principle called “Electromagnetic Induction” is used in

storage devices.

The case with which the material can be magnetized

is another parameter.

We know the soft magnetic materials are the

materials which can easily be magnetized and demagnetized. Hence a data can be

stored and erased easily. Such magnetic materials are used in temporary storage

devices.

Similarly, we know hard magnetic materials cannot

be easily magnetized and demagnetized. So such magnetic materials are used in

permanent storage devices.

In soft magnetic materials, the electrical

resistance varies with respect to the magnetization and this effect is called

magneto-resistance. This parameter is used in specific thin film systems.

The

magnetic medium is made of magnetic materials (Ferro or Ferric oxide) deposited

on this plastic.

The

magnetic medium move across the read / write heads and either logic 1’s and

logic 0’s are written on the medium. The magnetized spots on the medium

generate small electrical signals and this different direction signals

represents logic is and 0’s on the medium.

10.2

Storage of Magnetic Data

Memory

units are the devices used to store the information (Input and Output) in the

form of bits [8bits = 1 Byte].

The

memory units are classified into two categories.

Main memory (Primary) or Internal Memory.

Auxiliary Memory (Secondary) or External Memory.

Main

Memory

The

memory unit of the central processing unit (CPU) is called as main memory.

Compare a black beard main memory. We can write many data on memories and

finally erase it if we want.

Example :

RAM, ROM,

EPROM etc.

2. Auxiliary Memory

Since

storage capacity of primary memory is not sufficient secondary memory units are

developed to store the large volume of data. Separately and hence called as

extra (or) additional (or) external memory.

This type

of memory is also referred to as back up storages because, it is used to store

large volume of data on a permanent basis.

Example: 1.

Magnetic tapes

Magnetic

disk (Floppy and Hard disc)

Ferrite core memories

Magnetic bubble memories.

10.3 Magnetic

Tape

It is one

of the most popular storage medium for data. The tape is a plastic ribbon with

metal oxide material coated on one side which can be magnetized. In this,

information can be written and also can be read by read / write heads.

Information

recorded in the tape is in the form of tiny magnetized and non magnetized spots

on the metal oxide coating.

The

magnetized spot represents ‘I’ and un magnetized spot represent ‘0’ in binary

code. The information can be accessed, processed, erased and can be again

stored in the same area.

Advantages

Its storage capacity is large

It is easy to handle and is portable

Its cost is less than other storage devices.

It can be erased and reused may times.

Disadvantage

1. It

consumes lot of time.

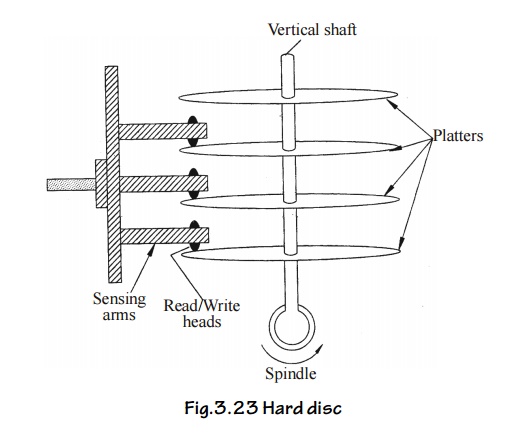

10.4

Magnetic Disc Drivers

These

disks are direct access storage devices. These disks are magnetically coated.

There are two types of disks.

Hard disc

Floppy disc

Hard disc

The hard

disc is made of hard aluminum platters. The platter surface is carefully

machined until it is flat (or) plane. The platter surface is coated with

magnetic material (magnetic oxides). The platter is built into a box.

Similar

such disks are mounted on a vertical shaft, forming a disk pack and it is shown

in fig.

Fig.3.23

Hard disc

The disc

pack is placed is a drive mechanism called hard disk drive. The drive mechanism

driver the disc pack with the spindle. The data is written (or) ready by R/ W

beads in the horizontal sensing arms by moving in an out between the platters

with the precaution that the R/W head doesn’t touch the surface instead, it fly

over the disk surface by a fraction of an mm.

Advantages

It has very large storage capacity.

Thousands of files can be permanently stored

Very high speed is reading and writing the

information.

This is prevented from dust particles, since they

are seated in special chamber.

Disadvantages

It is very costly.

It data is once corrupted, there is a heavy loss of

data.

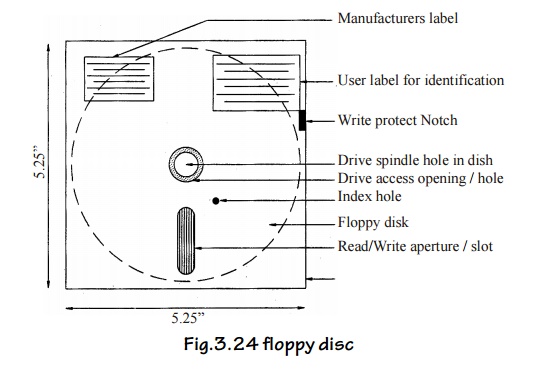

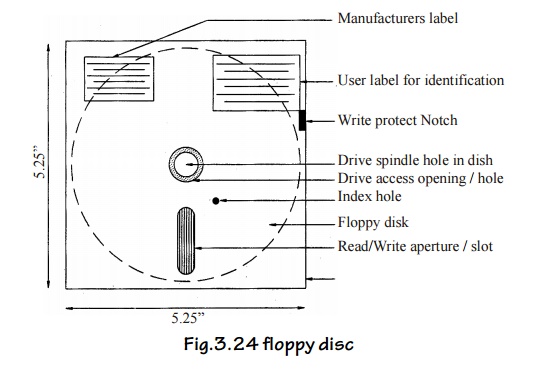

10.5

Floppy Disk

The hard

disc is suitable only for large and medium sized computers and often are too

expensive for small computers systems. Floppy disc are the latest development

in secondary storage devices.

It is

made up of a flexible plastic material and hence called as floppy disc. It is

also called as diskette. It acts both as an input and output device.

Fig.3.24 floppy disc

The disk is provided with a central hole. This

hole is used for mounting the disc in the floppy derive unit. The envelope

prevents the disk from dust and moisture.

There is a small index hole in the cover and

there will be a hole in the drive disk. When these two holes match then only

the storage operation can be started. Write protect notch is used to prevent

writing on the disc by other users. This can be done by covering the notch with

a sticker. A 5.25° floppy is shown in fig.

Writing

operation

When the floppy disk moves over the gap the CPU

flow through the write will of the head and magnetizes the iron oxide coating

in the disk to the proper pattern.

Reading

Operation

When the data are to be read, the magnetized

patterns induces pulses of current in the read coil and is amplified then fed

to the CPU. Thus data can be stored and accessed from the floppy disc on both

sides (or) single side. Reading / writing data on the magnetic medium using

frequently modulated wave.

Special features

The cost is very low

It can be easily handled

It can be taken to any place

It has high storage capacity

Many types of floppies are available, depending on

their storage capacities.

Disadvantage

Here the

magnetic disk is moved (rotated) mechanically.

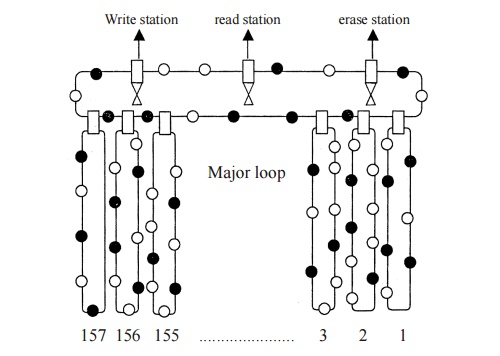

10.6

Magnetic bubble Materials

Magnetic

bubble is direct access storage medium, magnetic bubbles are soft magnetic

materials with magnetic domains of a few micrometers in diameter. These bubbles

are the electrical analogue of the magnetic disk memories used in computers.

The

magnetic disk in the hard disk memory is moved mechanically where as the

bubbles in a bubble memory device are moved electronically at very high speeds,

so the read out time or storing time is greatly reduced in bubble memory

device. The bubble units are made with solid state electronic chips.

A

magnetic bubble can be thought of as a positively charged and in a negatively

charged magnetic film.The presence of a bubble is on ‘ON’ condition and the

absence of a bubble is an ‘off’ condition. ie., [1 or 0].

Fig. 3.25

Magnetic bubble memory

Figure

shows the schematic diagram of a magnetic bubble memory. It consists of one

major loop and 157 minor loops. Each minor loop has 641 bubble sites.

Writing operation

When a

data is to be stored, the bubbles from the minor loops are transferred to the

major loop, and it goes to the write station. In write station the data is

entered and the bubble again comes to minor loop.

Reading operation

To read

the data from the storage, the bubble from minor loops are transferred to the

major loop and it goes to the read station, then it comes to the minor loop.

The data can be altered by the erase station, if we need to erase it.

Advantage

It is non-volatile.

It has high storage capacity than the magnetic hard

disk.

It has high across speed.

Construction

A Bubble

memory consist of materials such as magnetic garnets and store the data as

microscopic magnets. A thin film of these garnets is deposited on a

non-magnetic substrate of Gadolinium Gallium Garnet in Integrated Circuit [IC]

form.

Related Topics