Chapter: Modern Analytical Chemistry: The Language of Analytical Chemistry

Language of Analytical Chemistry: Developing the Procedure

Developing the

Procedure

After selecting a method, it is necessary to develop a procedure that will accomplish the goals of the analysis. In developing the procedure, attention is given to compen-

sating for interferences, selecting and calibrating equipment, standardizing the method, acquiring a representative sample, and validating the method.

Compensating for Interferences

The accuracy of a method

depends on its

selectivity for the

analyte. Even the

best methods, however, may not be free from interferents that contribute to the mea- sured signal. Potential interferents may be present in the sample itself or the reagents used during the analysis. In this section

we will briefly

look at how to mini- mize these two sources

of interference.

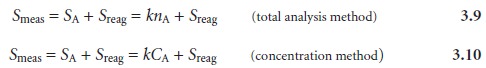

In the absence

of an interferent, the total

signal measured during

an analysis, Smeas, is a sum

of the signal

due to the

analyte, and the

signal due to the rea- gents, Sreag

Without an independent determination of Sreag, equation

3.9 or 3.10 cannot be solved for the moles

or concentration of analyte. The contribution of Sreag is deter- mined by measuring the

signal for a reagent or method

blank that does

not contain the sample.

Consider, for example, a procedure in which a 0.1-g sample

is dissolved in 100 mL of solvent. After dissolving the sample, several

reagents are added, and

the signal is measured. The reagent blank is prepared

by omitting the sample and adding the reagents to 100 mL of solvent.

When the sample

is a liquid, or is in solu- tion, an equivalent volume

of an inert solvent is substituted for

the sample. Once Sreag is known, it is easy to correct

Smeas for the reagent’s

contribution to the overall

signal.

Compensating for an interference in the sample’s

matrix is more difficult. If the

identity and concentration of the interferent are known, then it can be added

to the reagent blank. In most

analyses, however, the identity or concentration of matrix interferents is not

known, and their

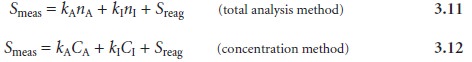

contribution to Smeas is not included in Sreag. In- stead, the signal

from the interferent is included as an additional term

Solving either equation

3.11 or 3.12 for the amount of analyte can be accomplished by separating the analyte

and interferent before the analysis,

thus eliminating the term for the interferent.

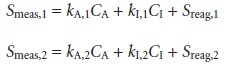

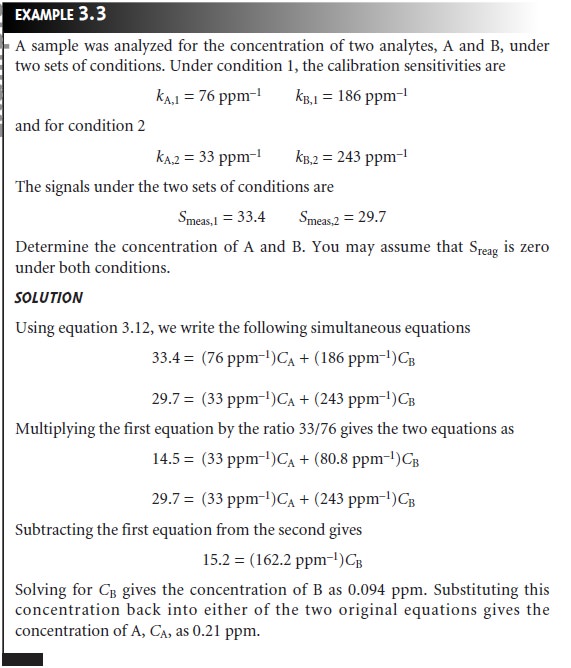

Alternatively, equations 3.11 or 3.12 can be solved for the amounts

of both the analyte and the interferent. To do so, however, we must obtain

two independent values for Smeas. Using a concentration method as an example, gives

two equations

that can be solved

simultaneously for CA and CI. This treatment is general. The composition of a solution

with a total of n analytes and interferents can be deter- mined by measuring n independent signals, and solving

n

independent simultane-

ous equations of the general

form of equation

3.11 or 3.12.

Calibration and Standardization

Analytical chemists make a distinction between calibration and standardization.9 Calibration ensures that the equipment or instrument used to measure

the signal is operating correctly by using

a standard known

to produce an exact signal.

Balances, for example, are calibrated using

a standard weight

whose mass can be traced

to the internationally accepted platinum–iridium prototype kilogram.

Standardization is the process of experimentally determining the relation- ship between the signal and the amount of analyte (the value of k in equations 3.1 and 3.2). For a total

analysis method, standardization is usually defined

by the stoichiometry of the chemical

reactions responsible for the signal.

For a con- centration method, however, the relationship between the signal and the ana- lyte’s

concentration is a theoretical function

that cannot be calculated without experimental measurements. To standardize a method, the value of k is deter-

mined by measuring the signal for one or more standards, each containing a known

concentration of analyte.

When several standards with different concen- trations of analyte are used, the result is best viewed

visually by plotting

Smeas versus the

concentration of analyte

in the standards. Such a plot

is known as a

calibration curve.

Sampling

Selecting an appropriate method helps ensure that an analysis is accurate. It does

not guarantee, however,

that the result

of the analysis will be sufficient to solve the problem under investigation or that a proposed answer will be correct. These latter

concerns are addressed by carefully collecting the samples

to be analyzed.

A proper sampling

strategy ensures that samples are representative of the mate- rial from which they are taken.

Biased or nonrepresentative sampling and contami- nation of samples during

or after their

collection are two sources of sampling error that can lead to significant errors.

It is important to realize

that sampling errors

are completely independent of analysis errors.

As a result, sampling errors

cannot be corrected by evaluating a reagent blank.

Validation

Before a procedure can provide useful

analytical information, it is necessary to demonstrate that it is capable

of providing acceptable results. Validation

is an eval- uation of whether the precision and accuracy obtained

by following the procedure

are appropriate for

the problem. In addition, validation ensures that the

written procedure has sufficient detail so that different analysts

or laboratories following the same procedure obtain

comparable results. Ideally, validation uses a standard sam- ple whose composition closely

matches the samples for which the procedure was developed. The comparison of replicate analyses

can be used to evaluate

the proce- dure’s precision and accuracy. Intralaboratory and interlaboratory differences in the procedure also

can be evaluated. In the absence

of appropriate standards, accuracy can be evaluated by comparing results

obtained with a new method

to those ob- tained using a method

of known accuracy.

Related Topics