Chapter: Optical Communication and Networking : Sources and Detectors

LEDs

LEDs

Spontaneous

emission of radiation in the visible and infrared regions of the spectrum from

a forward-biased p–n junction was discussed. The normally

empty conduction band of the semiconductor is populated by electrons injected

into it by the forward current through the junction, and light is generated

when these electrons recombine with holes in the valence band to emit a photon.

This is the mechanism by which light is emitted from an LED, but stimulated

emission is not encouraged, as it is in the injection laser, by the addition of

an optical cavity and mirror facets to provide feedback of photons.

The LED

can therefore operate at lower current densities than the injection laser, but

the emitted photons have random phases and the device is an incoherent optical

source. Also, the energy of the emitted photons is only roughly equal to the

band gap energy of the semiconductor material, which gives a much wider

spectral line width (possibly by a factor of 100) than the injection laser. The

line width for an LED corresponds to a range of photon energy between 1 and 3.5KT, where K is Boltzmann’s constant and T

is the absolute temperature.

This

gives linewidths of 30 to 40 nm for GaAs-based devices operating at room

temperature. Thus the LED supports many optical modes within its structure and

is therefore often used as a multimode source, although the coupling of LEDs to

single-mode fibers has been pursued with success, particularly when advanced

structures are employed. Also, LEDs have several further drawbacks in

comparison with injection lasers.

These

include:

ü generally

lower optical power coupled into a fiber (microwatts);

ü usually

lower modulation bandwidth;

ü harmonic

distortion.

However,

although these problems may initially appear to make the LED a less attractive

optical source than the injection laser, the device has a number of distinct

advantages which have given it a prominent place in optical fiber

communications:

ü Simpler fabrication. There

are no mirror facets and in some structures no striped geometry.

ü Cost. The simpler construction of the

LED leads to much reduced cost which is always likelyto be maintained.

ü Reliability. The LED does not exhibit

catastrophic degradation and has proved far lesssensitive to gradual

degradation than the injection laser. It is also immune to self-pulsation and

modal noise problems.

ü Generally less temperature dependence. The light

output against current characteristic is lessaffected by temperature than the

corresponding characteristic for the injection laser. Furthermore, the LED is

not a threshold device and therefore raising the temperature does not increase

the threshold current above the operating point and hence halt operation.

ü Simpler drive circuitry. This is

due to the generally lower drive currents and reducedtemperature dependence

which makes temperature compensation circuits unnecessary.

ü Linearity. Ideally, the LED has a linear

light output against current characteristic, unlike theinjection laser. This

can prove advantageous where analog modulation is concerned.

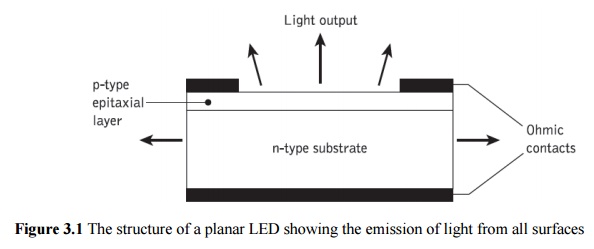

The

planar LED is the simplest of the structures that are available and is

fabricated by either liquid- or vapor-phase epitaxial processes over the whole

surface of a GaAs substrate. This involves a p-type diffusion into the n-type

substrate in order to create the junction illustrated in Figure 3.1. Forward

current flow through the junction gives Lambertian spontaneous emission and the

device emits light from all surfaces. However, only a limited amount of light

escapes the structure due to total internal reflection, and therefore the

radiance is low.

The

absence of optical amplification through stimulated emission in the LED tends

to limit the internal quantum efficiency (ratio of photons generated to

injected electrons) of the device. Reliance on spontaneous emission allows

nonradiative recombination to take place within the structure due to crystalline

imperfections and impurities giving, at best, an internal quantum efficiency of

50% for simple homojunction devices. However, as with injection lasers,

double-heterojunction (DH) structures have been implemented which recombination

lifetime measurements suggest give internal quantum efficiencies of 60 to 80%.

The power

generated internally by an LED may be determined by consideration of the excess

electrons and holes in the p- and n-type material respectively (i.e. the

minority carriers) when it is forward biased and carrier injection takes place

at the device contacts. The excess density of electrons Dn and holesDp is equal

since the injected carriers are created and recombined in pairs such thatcharge

neutrality is maintained within the structure.

Related Topics