Chapter: Mechanical : Automobile Engineering : Steering, Brakesa and Suspension Systems

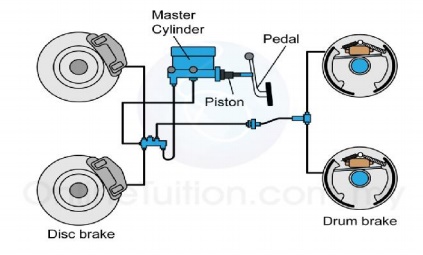

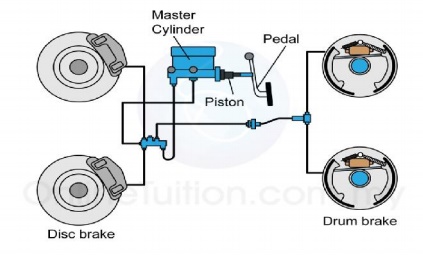

Hydraulic braking system

Hydraulic braking system

The disc brake or disk brake is a device for slowing or

stopping the rotation of a wheel while it is in motion. A brake disc (or rotor

in U.S. English) is usually made of cast iron, but may in some cases be made of

composites such as reinforced carbon-carbon or ceramic-matrix composites.

This is connected to the wheel and/or the axle. To stop the

wheel, friction material in the form of brake pads (mounted on a device called

a brake caliper) is forced mechanically, hydraulically, pneumatically or

electromagnetically against both sides of the disc. Friction causes the disc

and attached wheel to slow or stop. Brakes (both disc and drum) convert motion

to heat, but if the brakes get too hot, they will become less effective because

they cannot dissipate enough heat. This condition of failure is known as brake

fade.

Construction of Braking system;

The most common arrangement of hydraulic brakes for passenger

vehicles, motorcycles, scooters, and mopeds, consists of the following:

·

Brake pedal or lever

·

A pushrod (also called an actuating rod)

·

A master cylinder assembly containing a piston

assembly

·

Reinforced hydraulic lines

Brake caliper assembly usually consisting of one or two hollow

aluminum or chrome-plated steel pistons (called caliper pistons), a set of

thermally conductive brake pads and a rotor (also called a brake disc) or drum

attached to an axle.The system is usually filled with a glycol-ether based

brake fluid (other fluids may also be used).

At one time, passenger vehicles commonly employed drum brakes

on all four wheels. Later, disc brakes were used for the front and drum brakes

for the rear. However disc brakes have shown better heat dissipation and

greater resistance to 'fading' and are therefore generally safer than drum

brakes. So four-wheel disc brakes have become increasingly popular, replacing

drums on all but the most basic vehicles. Many two-wheel vehicle designs,

however, continue to employ a drum brake for the rear wheel.The following

description uses the terminology for and configuration of a simple

In a hydraulic brake system, when the brake pedal is pressed,

a pushrod exerts force on the piston(s) in the master cylinder, causing fluid

from the brake fluid reservoir to flow into a pressure chamber through a

compensating port. This results in an increase in the pressure of the entire

hydraulic system, forcing fluid through the hydraulic lines toward one or more

calipers where it acts upon one or two caliper pistons sealed by one or more

seated O-rings (which prevent leakage of the fluid).

The brake caliper pistons then apply force to the brake pads,

pushing them against the spinning rotor, and the friction between the pads and

the rotor causes a brakingtorque to be generated, slowing the vehicle. Heat

generated by this friction is either dissipated through vents and channels in

the rotor or is conducted through the pads, which are made of specialized

heat-tolerant materials such as kevlar orsintered glass.

Subsequent release of the brake pedal/lever allows the

spring(s) in my master cylinder assembly to return the master piston(s) back

into position. This action first relieves the hydraulic pressure on the

caliper, then applies suction to the brake piston in the caliper assembly,

moving it back into its housing and allowing the brake pads to release the

rotor.

The hydraulic braking system is designed as a closed system:

unless there is a leak in the system, none of the brake fluid enters or leaves

it, nor does the fluid get consumed through use.

Related Topics