Chapter: Mechanical : Maintenance Engineering : Repair Methods For Material Handling Equipment

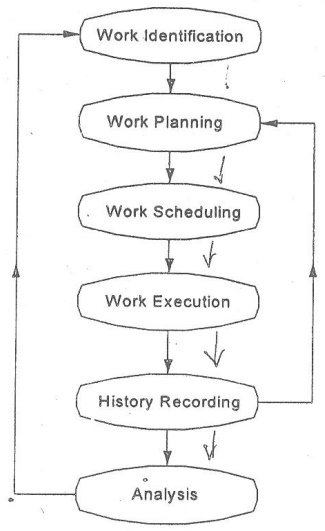

General structure of six phases of good maintenance management

General

structure of six phases of good maintenance management

The proper

operation of an industry requires appropriate strategies in maintenance management.This

is ensured by the effective integration of various phases involved in

management. A good maintenance management can be considered as having six phases

as shown.

They are

1

Work identification

2

Planning

3

Scheduling

4

Execution

5

Recording

6

Analysis

The important steps in this

system approach are

•

Codification and cataloguing

•

Preparation of history sheet

•

Preparation of instruction and operating manual

•

Preparation of maintenance manual

•

Maintenance operation liaison

•

Maintenance work order and permit system

•

Job execution, monitoring, feedback and control

General

structure of computerized maintenance management system

Computerized maintenance management system is the application

of computers in planning, scheduling, monitoring and control of maintenance

activities.

A computerized maintanance

management system includes the following aspects:

•

Development of a database

•

Analysis of available past records

•

Development of maintenance schedules

•

Availability of maintenance material

•

Feedback control system

•

Project management.

Te objectives of CMMS.

6.

Maintenance of existing equipments

7.

Inspection and service of the equipment

8.

installation or revamping of the equipment

9.

Maintenance storekeeping

10.

craft administration

11.

Te advantages of CMMS.

1. Improve

maintenance efficiency

2. Reduce

maintenance costs

3. Reduce the

equipment downtime by proper scheduling preventative maintenance.

4. provide maintenance

reports in specific

formats depending on the

requirements.

5. Quicker access

to plant maintenance statistics

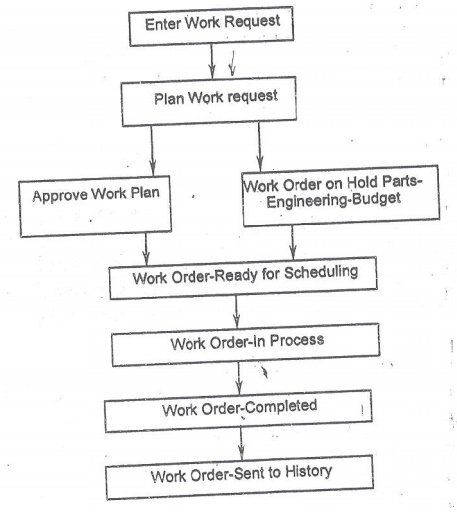

Work order flow diagram

Related Topics