Chapter: Mechanical : Kinematics of Machinery : Gears and Trains

Gears and Trains

Gears And Trains

1 Introduction

Introduction: The slip and creep in the belt

or rope drives is a common phenomenon, in the transmission of motion or power between two shafts. The effect of

slip is to reduce the velocity ratio of the drive. In precision machine, in

which a definite velocity ratio is importance (as in watch mechanism, special

purpose machines..etc), the only positive drive is by means of gears or toothed

wheels.

Friction

Wheels: Kinematiclly, the motion and power transmitted by gears is equivalent

to that transmitted by friction wheels or discs in contact with sufficient

friction between them. In order to understand motion transmitted by two toothed

wheels, let us consider the two discs placed together.

When one

of the discs is rotated, the other disc will be rotate as long as the

tangential force exerted by the driving disc does not exceed the maximum

frictional resistance between the two discs. But when the tangential force

exceeds the frictional resistance, slipping will take place between the two

discs. Thus the friction drive is not positive a drive, beyond certain limit.

Gears are

machine elements that transmit motion by means of successively engaging teeth.

The gear teeth act like small levers. Gears are highly efficient (nearly 95%)

due to primarily rolling contact between the teeth, thus the motion transmitted

is considered as positive.

Gears

essentially allow positive engagement between teeth so high forces can be

transmitted while still undergoing essentially rolling contact. Gears do not

depend on friction and do best when friction is minimized.

Gears are

used to change speed in rotational movement.

In the

example above the blue gear has eleven teeth and the orange gear has twenty

five. To turn the orange gear one full turn the blue gear must turn 25/11 or

2.2727r turns. Notice that as the blue gear turns clockwise the orange gear

turns anti-clockwise. In the above example the number of teeth on the orange

gear is not divisible by the number of teeth on the blue gear. This is

deliberate. If the orange gear had thirty three teeth then every three turns of

the blue gear the same teeth would mesh together which could cause excessive

wear. By using none divisible numbers the same teeth mesh only every seventeen

turns of the blue gear.

A gear or

cogwheel is a rotating machine part having cut teeth, or cogs, which mesh with

another toothed part to transmit torque. Geared devices can change the speed,

torque, and direction of a power source. Gears almost always produce a change

in torque, creating a mechanical advantage, through their gear ratio, and thus

may be considered a simple machine. The teeth on the two meshing gears all have

the same shape.[1] Two or more meshing gears, working in a sequence, are called

a gear train or a transmission. A gear can mesh with a linear toothed part,

called a rack, thereby producing translation instead of rotation.

The gears

in a transmission are analogous to the wheels in a crossed belt pulley system.

An advantage of gears is that the teeth of a gear prevent slippage.

When two

gears mesh, if one gear is bigger than the other, a mechanical advantage is

produced, with the rotational speeds, and the torques, of the two gears

differing in proportion to their diameters.

In

transmissions with multiple gear ratios—such as bicycles, motorcycles, and

cars—the term "gear" as in "first gear" refers to a gear

ratio rather than an actual physical gear. The term describes similar devices,

even when the gear ratio is continuous rather than discrete, or when the device

does not actually contain gears, as in a continuously variable transmission.

1.1 Fundamental Law of Gear-Tooth

Pitch point divides the line between the line of centers and its positiond ecides the velocity ratio of the two teeth. The above expression is the fundamental law of gear-tooth action.

Formation of teeth:

Involute

teeth

Cycloidal

teeth

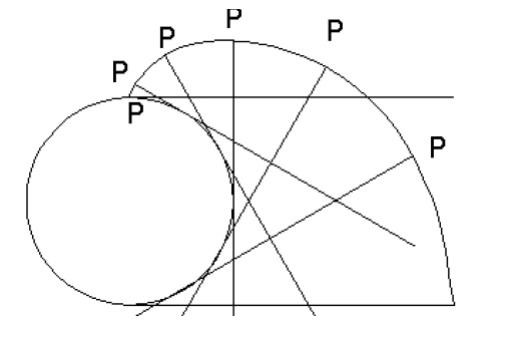

Involute curve:

The curve most commonly use d for gear-tooth

profiles is the involute of a circle. This involute

curve is the path traced by a point on a line as the line Rolls without

slipping on the circumference of a circle. It may also be defined

asapathtraced by the end of a string,

which is originally wrapped on a circle when the string is un wrapped from the

circle. The circle from which the involute is derived is called the base circle

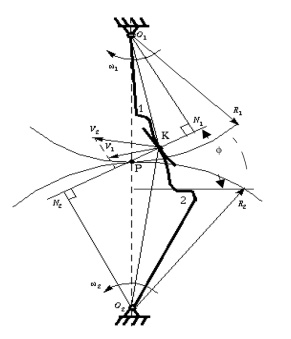

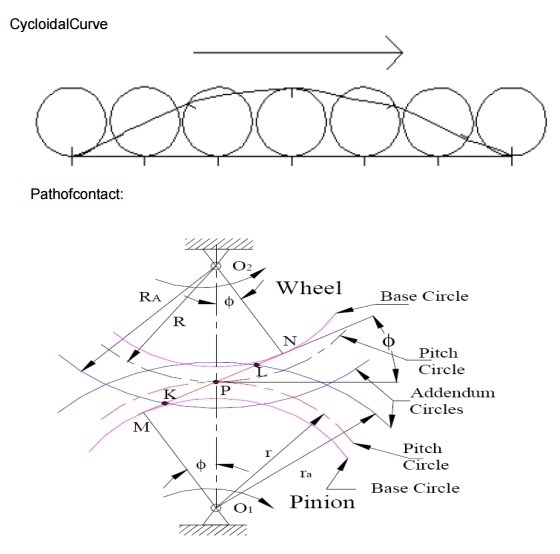

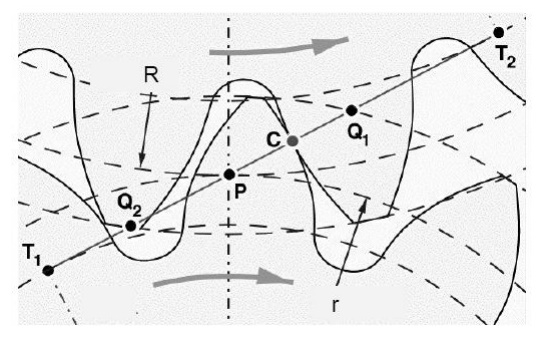

Consider a pinion driving wheel as shown in figure.

When the pinion rotates in clockwise, the contact between a pair of involute

teeth begin sat K(on the near the

base circle of pinion or the outer end of the tooth face on the wheel ) and end sat L (outer end of the tooth face on the pinion

or on the flank near the base circle of wheel).

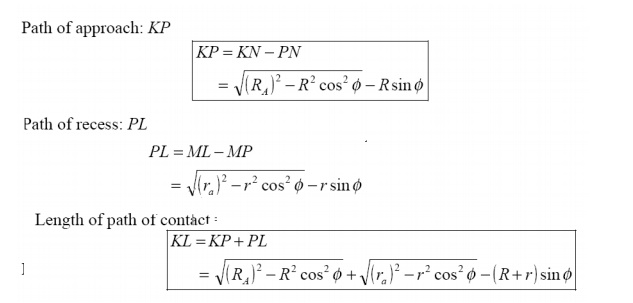

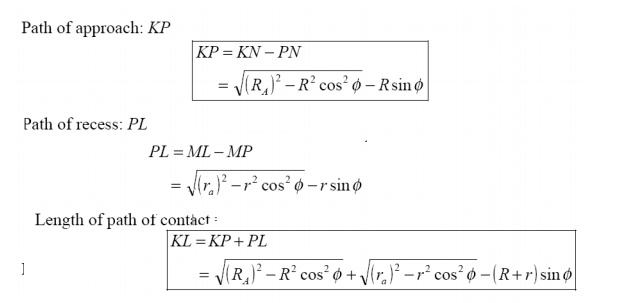

MN is the

common normal at the point of contacts and the common tangent to the base circles. The point K is the intersection of the addendum circle of wheel and the

common tangent. The point L is the

intersection of the addendum circle of pinion and common tangent.

The

length of path of contact is the length of common normal cut-off by theaddendum

circles of the wheel and the pinion. Thus the length of part of contact is KL which is the sum of the

parts of path of contacts KP

and PL. Contact length KP is called as path of approach and contact length PL is called as path of

recess.

Arc of contact: Arc of

contact is the path traced by a point on the pitch circle from the beginning to the end of engagement of a given

pair of teeth. In Figure, the arc of contact is EPF or GPH.

The arc

GP is known as arc of approach and the arc PH is called arc of recess. The

angles subtended by these arcs at O1 are called angle of approach and angle of

recess respectively.

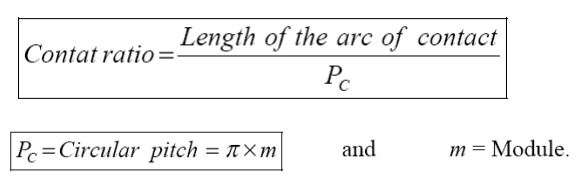

Contact Ratio ( or Number of

Pairs of Teeth in Contact)

The contact ratio or the number of pairs of teeth

in contact is defined as the ratio of the length of the arc of contact to the

circular pitch.

Continuous

motion transfer requires two pairs of

teeth in contact at the ends of the path

of contact, though the reisonly one pair in contact in the middle of the

path, as in Figure. The average

number of teeth in contact is an important parameter-If it is tool owdue the

use of inappropriate profile shift sortoan excessive centre distance. Them

anufacturinginaccuracies may lead to loss of kinematic continuity-that is to

impact, vibration and noise The average number of teeth in contact is also a

guide tolod sharing between teeth; it is termed the contact ratio.

The tooth

tip of the pinion will then undercut the tooth on the wheel at the root and

damages part of the involute profile. This effect is known as interference, and occurs when the teeth

are being cut and weakens the tooth at its root.

In

general, the phenomenon, when the tip of tooth undercuts the root on its mating

gear is known as interference.

Similarly,

if the radius of the addendum circles of the wheel increases beyond O2M,

then the tip of tooth on wheel will cause interference with the tooth on

pinion. The points M and N are called interference points.

Interference

may be avoided if the path of the contact does not extend beyond interference

points. The limiting value of the radius of the addendum circle of the pinion

is O1N and of the wheel is O2M.

The

interference may only be prevented, if the point of contact between the two

teeth is always on the involute profiles and if the addendum circles of the two

mating gears cut the common tangent to the base circles at the points of

tangency.

When

interference is just prevented, the maximum length of path of contact is MN.

Methods to avoid Interference

1.

Height of the teeth may be reduced.

2.Under cut

of the radial flank of the pinion.

3.Centre

distance may be increased. It leads to

increase in pressure angle.

4. By tooth

correction, the pressure angle, centre distance and base circles remain unchanged,

but tooth thickness of gear will be greater than the pinion tooth thickness.

Minimum

number of teeth on the pinion avoid Interference

The

pinion turns clockwise and drives the gear as shown in Figure.

Points M

and N are called interference points. i.e., if the contact takes place beyond M

and N, interference will occur.

The

limiting value of addendum circle radius of pinion is O1N and the

limiting value of addendum circle radius of gear is O2M. Considering

the critical addendum circle radius of gear, the limiting number of teeth on

gear can be calculated.

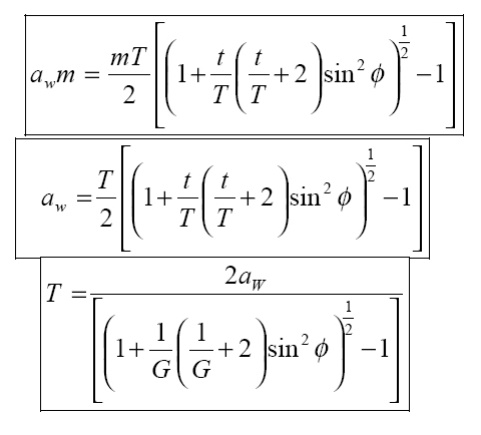

Let

Ф = pressure angle

R = pitch

circle radius of gear = ½ mT

r = pitch

circle radius of pinion = ½ mt

T & t

= number of teeth on gear & pinion

m =

module

2 Spur Gear Terminology

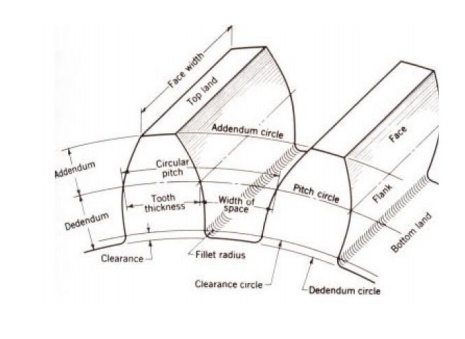

Addendum: The radial distance between the

Pitch Circle and the top of the teeth.

Arc of Action: Is the arc of the Pitch Circle

between the beginning and the end of the

engagement of a given pair of teeth.

Arc of Approach: Is the arc of the Pitch Circle

between the first point of contact of the gear teeth and the Pitch Point.

Arc of Recession: That arc

of the Pitch Circle between the Pitch Point and the last point of contact of the gear teeth.

Backlash: Play between mating teeth.

Base Circle: The circle from which is

generated the involute curve upon which the tooth profile is based.

Center Distance: The distance between centers of

two gears.

Chordal Addendum: The

distance between a chord, passing through the points where the Pitch Circle crosses the tooth profile, and

the tooth top.

Chordal Thickness: The

thickness of the tooth measured along a chord passing through the points where the Pitch Circle crosses

the tooth profile.

Circular Pitch: Millimeter of Pitch Circle circumference

per tooth.

Circular Thickness: The

thickness of the tooth measured along an arc following the Pitch Circle

Clearance: The distance between the top of a

tooth and the bottom of the space into which it fits on the meshing gear.

Contact Ratio: The ratio of the length of the

Arc of Action to the Circular Pitch.

Dedendum: The radial distance between the

bottom of the tooth to pitch circle.

Diametral Pitch: Teeth per mm of diameter.

Face: The working surface of a gear

tooth, located between the pitch diameter and the top of the tooth.

Face Width: The width of the tooth measured

parallel to the gear axis.

Flank: The working surface of a gear

tooth, located between the pitch diameter and the bottom of the teeth

Gear: The larger of two meshed gears.

If both gears are the same size, they are both called "gears".

Land: The top surface of the tooth.

Line of Action: That line along which the point

of contact between gear teeth travels, between the first point of contact and the last.

Module: Millimeter of Pitch Diameter to

Teeth.

Pinion: The smaller of two meshed gears.

Pitch Circle: The

circle, the radius of which is equal to the distance from the center of the

gear to the pitch point.

Diametral pitch: Teeth per millimeter of pitch

diameter.

Pitch Point: The point of tangency of the

pitch circles of two meshing gears, where the Line of Centers crosses the pitch circles.

Pressure Angle: Angle between the Line of Action

and a line perpendicular to the Line of Centers.

Profile Shift: An increase in the Outer Diameter

and Root Diameter of a gear, introduced to

lower the practical tooth number or acheive a non-standard Center Distance.

Ratio: Ratio of the numbers of teeth on

mating gears.

Root Circle: The circle that passes through

the bottom of the tooth spaces.

Root Diameter: The diameter of the Root Circle.

Working Depth: The depth to which a tooth extends into the space between teeth on the mating gear.

3 Worm, Rack and Pinion Gears

RACK AND

PINION WORM GEAR

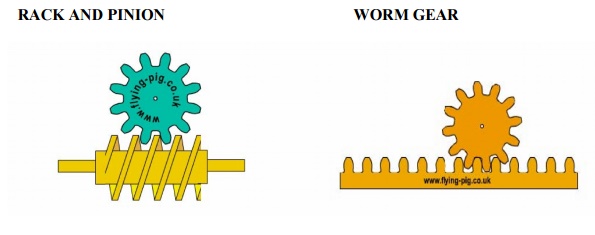

RACK AND PINION: The rack and pinion is used to

convert between rotary and linear motion.

The rack is the flat, toothed part, the pinion is the gear. Rack and pinion

can convert from rotary to linear of from linear to rotary. The diameter of the

gear determines the speed that the rack moves as the pinion turns. Rack and

pinions are commonly used in the steering system of cars to convert the rotary

motion of the steering wheel to the side to side motion in the wheels. Rack and

pinion gears give a positive motion especially compared to the friction drive

of a wheel in tarmac. In the rack and pinion railway a central rack between the

two rails engages with a pinion on the engine allowing the train to be pulled

up very steep slopes.

WORM GEAR: A worm is used to reduce speed.

For each complete turn of the worm shaft the gear shaft advances only one tooth of the gear. In this case, with a

twelve tooth gear, the speed is reduced by a factor of twelve. Also, the axis

of rotation is turned by 90 degrees. Unlike ordinary gears, the motion is not

reversible, a worm can drive a gear to reduce speed but a gear cannot drive a

worm to increase it. As the speed is reduced the power to the drive increases

correspondingly. Worm gears are a compact, efficient means of substantially

decreasing speed and increasing power. Ideal for use with small electric

motors.

4 Parallel axis gear trains:

·

Simple Gear Trains – A

simple gear train is a collection of meshing gears where each gear is on

its own axis. The train ratio for a simple gear train is the ratio of the

number of teeth on the input gear to the number of teeth on the output gear. A

simple gear train will typically have 2 or 3 gears and a gear ratio of 10:1 or

less. If the train has 3 gears, the intermediate gear has no numerical effect

on the train ratio except to change the direction of the output gear.

Compound

Gear Trains – A compound gear train is a train where at least

one shaft carries more than one gear. The train ratio is given by the ratio mV =

(product of number of teeth on driver gears)/(product of number of teeth on

driven gears). A common approach to the design of compound gear trains is to

first determine the number of gear reduction steps needed (each step is typically

smaller than 10:1 for size purposes). Once this is done, determine the desired

ratio for each step, select a pinion size, and then calculate the gear size.

·

Reverted Gear Trains – A

reverted gear train is a special case of a compound gear train. A reverted

gear train has the input and output shafts in –line with one another. Assuming

no idler gears are used, a reverted gear train can be realized only if the

number of teeth on the input side of the train adds up to the same as the

number of teeth on the output side of the train.

5 Epicyclic gear trains:

·

If the axis of the shafts over which the gears are

mounted are moving relative to a fixed axis , the gear train is called the

epicyclic gear train.

·

Problems in epicyclic gear trains.

Differentials:

·

Used in the rear axle of an automobile.

·

To enable the rear wheels to revolve at different

speeds when negotiating a curve.

·

To enable the rear wheels to revolve at the same

speeds when going straight.

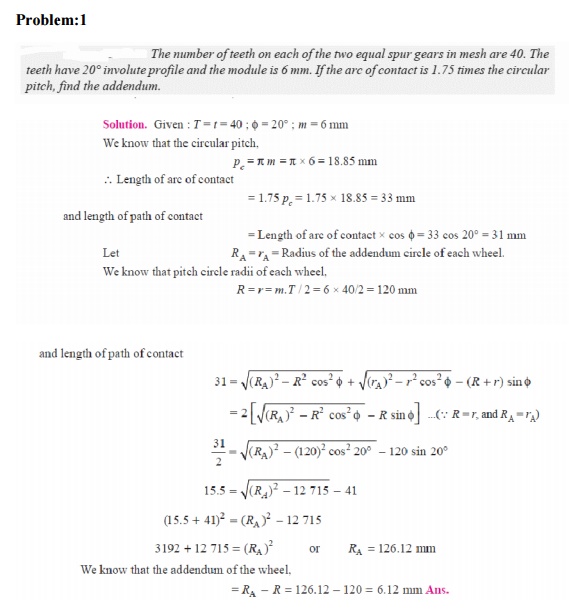

Problem:1

Related Topics