Chapter: Civil : Prestressed Concrete Structures : Circular Prestressing

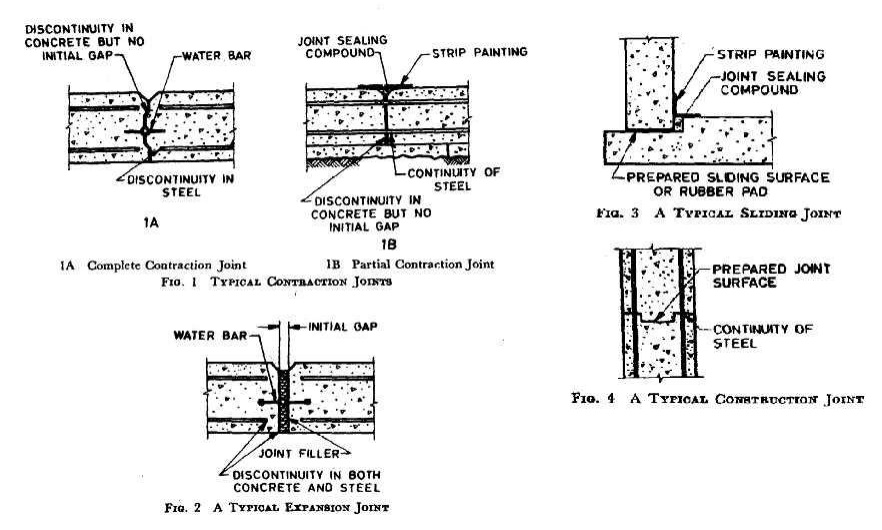

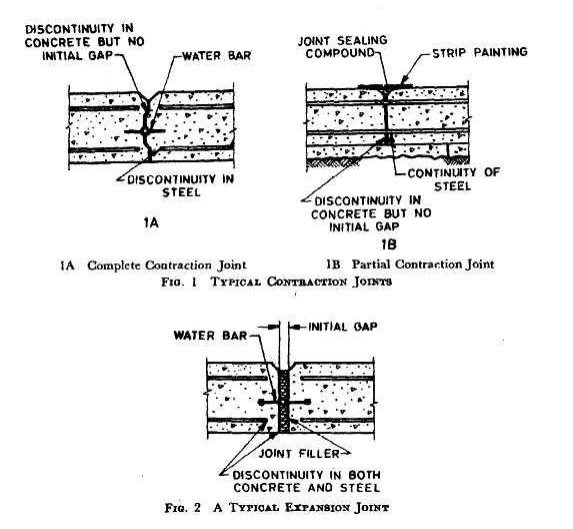

Different types of joints used between the slab of prestressed concrete tank

The

different types of joints used between the slab of prestressed concrete tank

Joints

shall be categorized as below:

a) Movetnent Joints -

There are three categories of movement joints:

contraction joint - A

movement joint with a deliberate discontinuity but no initial gap between the

concrete on either side of the joint, the joint being intended to accommodate

contraction of the concrete ( see Fig. 1 ).

A distinction should be

made between a complete contraction joint (see Fig. 1A ) in which both concrete

and reinforcing steel are interrupted, and a partial contraction joint (. see

Fig. 1B ) in which only the concrete is interrupted, the reinforcing steel

running through.

Expansion joint -

A movement joint with complete discontinuity in both reinforcement and

concrete and intended to accommodate either expansion or contraction of the

structure (see Pig. 2).

In general, such a

joint requires the provision of an initial gap between the adjoining parts of a

structure which by closing or opening accommodates the expansion or contraction

of the structure. Design of the joint so as to incorporate sliding surfaces, is

not, however, precluded and may sometimes be advantageous.

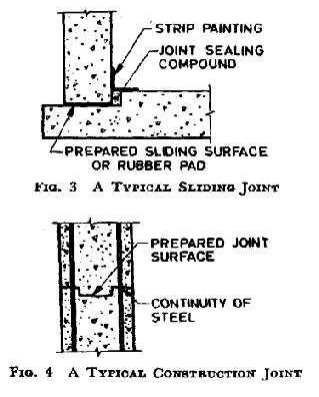

b)

Construction Joint-A joint in the concrete introduced for convenience in

construction at which special measures are taken to achieve subsequent

continuity without provision for further relative movement, is called a

construction joint. A typical application is between successive lifts in a

reservoir.

The position and

arrangement of all construction joints should be predetermined by the engineer.

Consideration should be given to limiting the number of such joints and to

keeping them free from possibility of percolations in a similar manner to

contraction joints.

c) Temporary Open

Joints - A gap temporarily left between the concrete of adjoining

parts of a structure which after a suitable interval and before the structure

is put into use, is filled with mortar or concrete either completely (

Fig. 5A) or as provided below, with the inclusion of suitable jointing

materials ( Fig. 5B and SC). In the former case the width of the gap should be

sufficient to allow the sides to be prepared before filling.

Where

measures are taken for example, by the inclusion of suitable jointing materials

to maintain the water tightness of the concrete subsequent to the filling of

the joint, this type of joint may be regarded as being equivalent to a

contraction joint ( partial or complete ) as defined above.

(b) Design the circular tank (only procedure.

in the construction of concrete

structures for the storage of liquids, the imperviousness of concrete is an

important basic requirement. Hence, the design of such construction is based on

avoidance of cracking in the concrete. The structures are prestressed to avoid

tension in the concrete. In addition, prestressed concrete tanks require low

maintenance. The resistance to seismic forces is also satisfactory.

Prestressed concrete tanks are used in water

treatment and distribution systems, waste water collection and treatment system

and storm water management. Other applications are liquefied natural gas (LNG)

containment structures, large industrial process tanks and bulk storage tanks.

The construction of the tanks is in the following sequence. First, the concrete

core is cast and cured. The surface is prepared by sand or hydro blasting.

Next, the circumferential prestressing is applied by strand wrapping machine.

Shotcrete is applied to provide a coat of concrete over the prestressing

strands.

Analysis

The analysis of liquid

storage tanks can be done by IS:3370 - 1967,

Part 4, or by the finite element method. The Code provides

coefficients for bending moment, shear and hoop tension (for cylindrical

tanks), which were developed from the theory of plates and shells. In Part 4, both rectangular and cylindrical tanks

are covered. Since circular prestressing is applicable to cylindrical tanks,

only this type of tank is covered in this module.

The following types of boundary conditions are

considered in the analysis of the cylindrical wall.

a) For

base: fixed or hinged

b) For

top: free or hinged or framed.

For

base

Fixed: When the wall is built continuous with its

footing, then the base can be considered to be fixed as the first

approximation.

Hinged: If the sub

grade is susceptible to settlement, then a hinged base is a conservative

assumption. Since the actual rotational restraint from the footing is somewhere

in between fixed and hinged, a hinged base can be assumed.

The base can be made

sliding with appropriate polyvinyl chloride (PVC) water-stops for liquid

tightness.

For top

Free: The top of the

wall is considered free when there is no restraint in expansion. Hinged: When

the top is connected to the roof slab by dowels for shear transfer, the

boundary condition can be considered to be hinged.

Framed: When the top of

the wall and the roof slab are made continuous with moment transfer, the top is

considered to be framed. The hydrostatic pressure on the wall increases

linearly from the top to the bottom of the liquid of maximum possible depth. If

the vapour pressure in the free board is negligible, then the pressure at the

top is zero. Else, it is added to the pressure of the liquid throughout the

depth. The forces generated in the tank due to circumferential prestress are

opposite in nature to that due to hydrostatic pressure. If the tank is built

underground, then the earth pressure needs to be considered. The hoop tension

in the wall, generated due to a triangular hydrostatic pressure is given as

follows.

The hoop tension in the

wall, generated due to a triangular hydrostatic pressure is given as follows.

T = CT w H Ri (9-6.15)

The bending moment in the vertical direction is

given as follows. M = CM w H3 (9-6.16)

The shear at the base is given by the following

expression. V = CV w H2 (9-6.17)

In

the previous equations, the notations used are as follows. CT = coefficient for

hoop tension

CM = coefficient for bending moment CV = coefficient

for shear

w = unit weight of liquid H = height of the liquid

Ri = inner radius of the wall.

The values of the

coefficients are tabulated in IS:3370 - 1967, Part

4, for various values of H2/Dt, at different depths of the liquid. D

and t represent the inner diameter and the thickness of the wall, respectively.

The typical variations of CT and CM with depth, for two sets of boundary

conditions are illustrated.

The roof can be made of

a dome supported at the edges on the cylindrical wall. Else, the roof can be a

flat slab supported on columns along with the edges.

IS:3370 - 1967, Part 4,

provides coefficients for the analysis of the floor and roof

slabs.

Design

IS:3370 - 1967, Part 3,

provides design requirements for prestressed tanks. A few

of them are mentioned.

1)

The computed stress in the concrete and

steel, during transfer, handling and construction, and under working loads,

should be within the permissible values as specified in IS:1343 - 1980.

2) The

liquid retaining face should be checked against cracking with a load factor of

1.2. ?CL/?WL ?1.2 (9-6.18)

Here,

?CL = stress under cracking load

?WL = stress under working load.

Values of limiting tensile strength of concrete for

estimating the cracking load are Specified in the Code.

3) The

ultimate load at failure should not be less than twice the working load.

When the tank is full, there should be compression

in the concrete at all points of at least 0.7 N/mm2. When the tank is empty,

there should not be tensile stress greater than 1.0 N/mm2. Thus, the tank

should be analysed both for the full and empty conditions.

5) There should be provisions to allow for elastic

distortion of the structure during prestressing. Any restraint that may lead to

the reduction of the prestressing force, should be considered.

Related Topics