Chapter: Civil : Prestressed Concrete Structures : Circular Prestressing

Design of circular water tanks

Design of circular water tanks

Concrete liquid retaining structures

must be impervious. Hence, their design is based on no in cracking in concrete.

Circular pre-stressed liquid retaining structures, are stressed to avoid

tension in concrete.

Pre-stressed concrete liquid

retaining structures require low maintenance and resist seismic forces

satisfactory.

Circular pre-stressed concrete tanks

are used in water treatment, water distribution, storm water management, large

industrial tanks, bulk storage tanks and for storing liquefied natural gas

(LNG).

The construction of the circular

tanks is in the following sequence. First, the concrete core is cast and cured.

The surface is prepared by sand or hydro blasting. Next, the circumferential

pre-stressing is applied by strand wrapping machine. Shotcrete is applied to

provide a coat of concrete over the pre-stressing strands.

IS:3370-1967 (1-4) Code of Practice

for Concrete Structures for the Storage of Liquids provides guidelines for the

analysis and design of liquid storage tanks. The four sections of the code are

titled as follows:

Part 1: General Requirement.

Part 2: Reinforced Concrete

Structures.

Part 3: Pre-stressed Concrete

Structures.

Part 4: Design Tables.

In IS:3370-1967 (3), the design

requirements for pre-stressed tanks are mentioned. A few of them are:

1. The computed stress in the

concrete and steel, during transfer, handling and construction, and under

working loads, should be within the permissible values as specified in

IS:1343-1980.

2. The liquid retaining face should

be checked against cracking with a load factor of 1.2.

3. The ultimate load at failure

should not be less than twice the working load.

4. When the tank is full, there

should be compression in the concrete at all points of at least 0.7 N/mm2.

When the tank is empty, there should not be tensile stress greater than 1.0

N/mm2. Thus, the tank should be analyzed both for the full and empty

conditions.

5. There should be provisions to

allow for elastic distortion of the structure during pre-stressing. Any

restraint that may lead to the reduction of the pre-stressing force should be

considered.

6. The cover requirement is as

follows. The minimum cover to the pre-stressing wires should be 35 mm on the

liquid face. For faces away from the liquid, the cover requirements are as per

IS:1343-1980.

The general equations from Eq 1 to Eq

3, would serve well for the design of circular pre-stressed liquid retaining

structure.

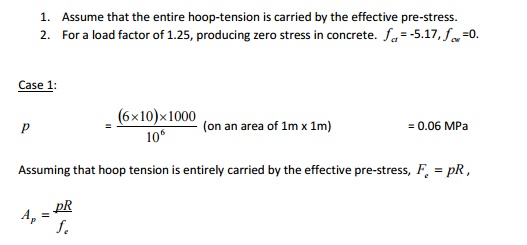

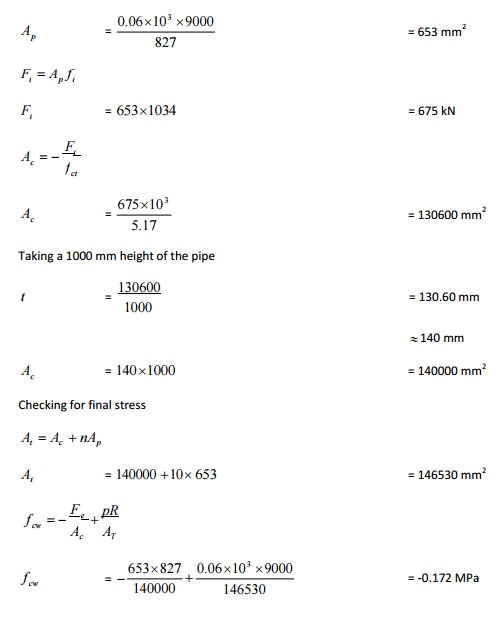

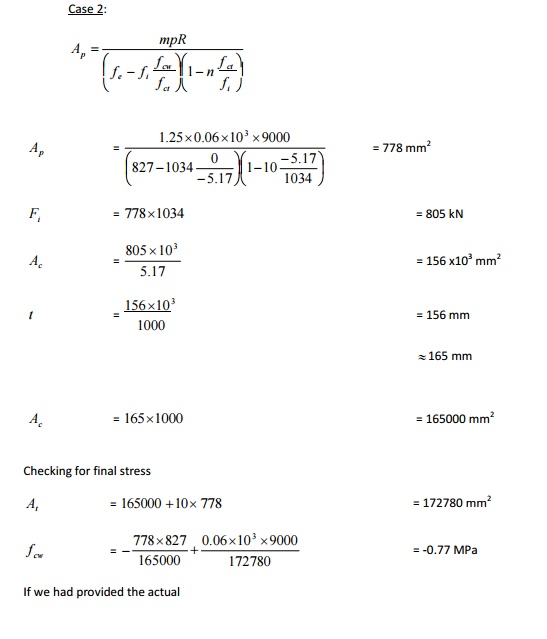

Example

Determine the area of steel required

per meter height of a circular pre-stressed water tank with an inside diameter

of 18 m and a height of 6 m water pressure. Compute the thickness of concrete

required.

f i = 1034 MPa, f e

= 827 MPa, f ct = -5.17, MPa and n = 10.

Design for the following two cases:

Related Topics