Chapter: Civil : Prestressed Concrete Structures : Circular Prestressing

Design of pipes

Design of pipes

Pre-stressed concrete pipes are

suitable when the internal pressure is within 0.5 to 2.0

Mpa. There are two types of

pre-stressed concrete pipes:

1. Cylinder type which has a steel

cylinder core, over which the concrete is cast and pre-stressed.

2.

Non-cylinder type which is made of

pre-stressed concrete only.

IS:784-2001 Pre-stressed Concrete

Pipes (Including Specials), provides guidelines for the design of pre- stressed

concrete pipes with the internal diameter ranging from 200 mm to 2500 mm. The

pipes are designed to withstand the combined effect of internal pressure and

external loads. The minimum grade of concrete in the core should be M40 for

non-cylinder type pipes.

The pipes are manufactured either by,

1. Centrifugal method: In the

centrifugal method the mould is subjected to spinning till the concrete is

compacted to a uniform thickness throughout the length of the pipe.

2. Vertical casting method: In the vertical

casting method, concrete is poured in layers up to a specified height.

After adequate curing of

concrete, first the longitudinal wires are pre-stressed. Subsequently, the

circumferential pre-stressing is done by the wire wound around the core in a

helical form. The wire is wound using a counter weight or a die. Finally a coat

of concrete or rich cement mortar is applied over the wire to prevent from

corrosion. For cylinder type pipes, first the steel cylinder is fabricated and

tested. Then the concrete is cast around it.

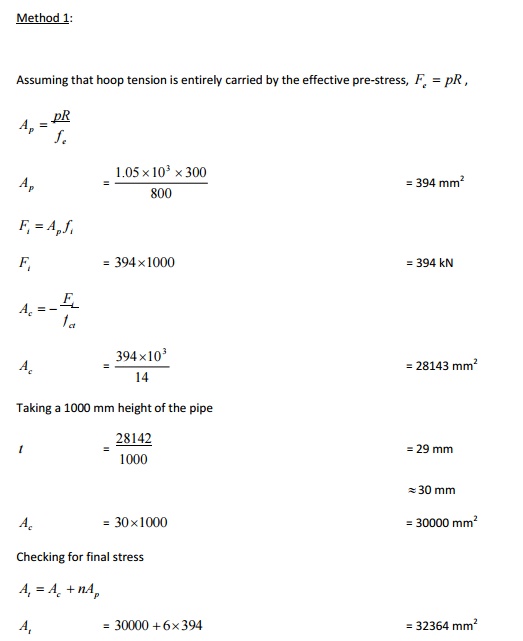

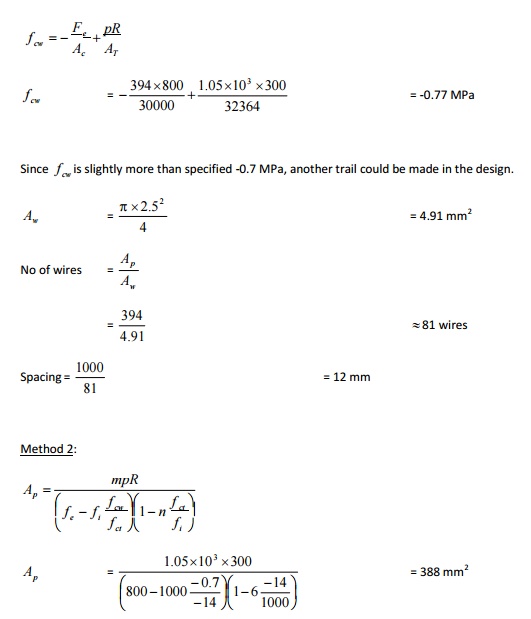

Example 1 - non-cylinder

Design a non-cylinder pre-stressed

pipe for the following specifications: R = 300 mm, p = 1.05 MPa, fi = 1000 MPa,

fe = 800 MPa, f ct = -14 MPa, f cw =-0.7 MPa, Es = 2.1x105 MPa, Ec =

0.35 x 105 MPa and 2.5 mm wires are used. And what would be the

internal pressure 'p' required to balance the pre-stress at transfer before

losses to maintain a stress of -0.7 in concrete?

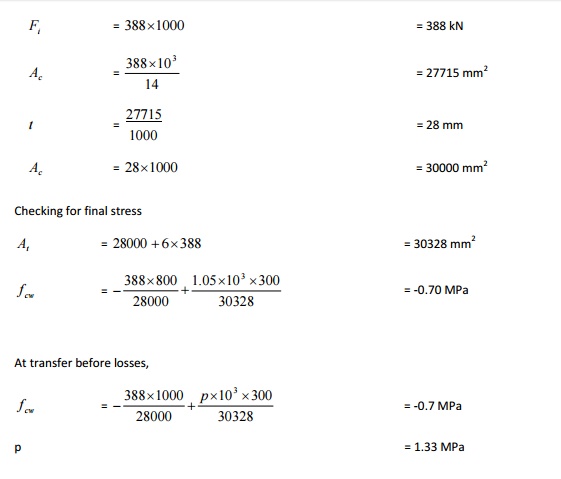

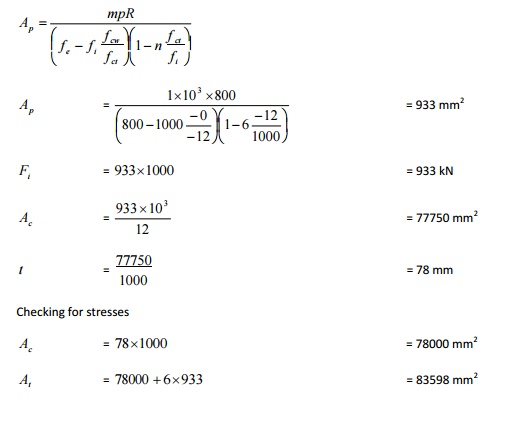

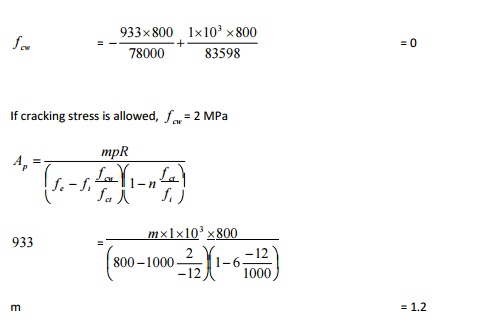

Example 2 - non-cylinder

Design a non-cylinder pre-stressed

pipe for the following specifications: R = 800 mm, p = 1 MPa, fi =

1000 MPa, fe = 800 MPa, fct = -12 MPa, fcw =

0, Es = 2.1x105 MPa, Ec = 0.35 x 10 5 MPa and 5 mm wires are used.

If cracking stress is +2 MPa, what is the F.S against cracking?

Related Topics