Chapter: Civil Engineering : Building Components and Structures

Conventional spread footings: R.C.C. footings and Grillage footing

Conventional spread footings

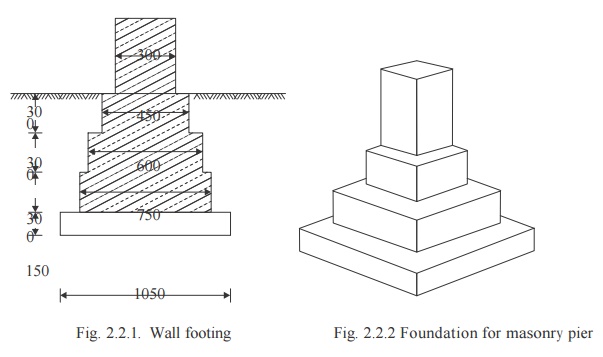

This type of

foundations is commonly used for walls and masonry columns. These foundations

are built after opening the trenches to required depth. Such footings are

economical up to a maximum depth of 3 m. As these foundations are suitable

depth, they are grouped under shallow foundations.

Figure 2.2.1 shows

a conventional spread footing for a wall and Fig. 2.2.2 shows it for a masonry

column.

Fig. 2.2.1. Wall footing Fig. 2.2.2 Foundation for masonry pier

Before building

these footing trenches are opened to required depth and the soil is rammed

well. Then a plain concrete of mix 1 : 4 : 8 is provided. Its thickness varies

from 150 to 200 mm. Over this bed, stone masonry footing is built. It is built

in courses each course projecting 50 to 75 mm from the top course and height of

each course being 150 to 200 mm. In case of wall footing the projections are

only one direction while in case of columns, they are in both directions. The

projection of bed concrete from the lowest course of foundation masonry is

usually 150 mm.

R.C.C. footings

There are mainly two types of R.C.C. footings:

1.

One way reinforced footings.

2.

Two way reinforced footings.

1. One Way Reinforced Footing: These

footings are for the walls. In these footings main reinforcements are in

the transverse direction of wall. In longitudinal directions there will be only

nominal reinforcement.

2. Two Way Reinforced Footings: For columns

two way reinforced footings are provided. The following types of the

footings are common:

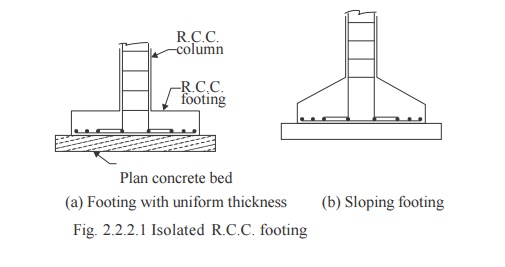

(i) Isolated Column Footings:

If separate footings are provided for each column, it is

called isolated column footing. Figure 2.2.2.1 shows a typical isolated column

footing. The size of footing is based on the area required to distribute the

load of the columns safely over the soil .These footings are provided over a

100 to 150 mm bed concrete. Required reinforcements and thickness of footing

are

found by the design engineers. Thickness may be uniform or

varying.

(a) Footing with uniform thickness (b) Sloping footing

Fig. 2.2.2.1 Isolated R.C.C. footing

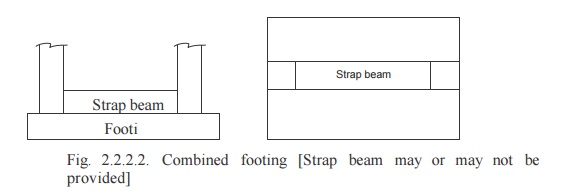

(ii) Combined Footings: Common footings may be provided for two columns. This

type of footing is necessary when a column is very close to the boundary of the

property and hence there is no scope to project footing much beyond the column

face. Figure 2.2.2.2 shows a typical combined footing. The footing is to be

designed for transferring loads from both columns safely to the soil. The two

columns may or may not be connected by a strap beam.

Fig. 2.2.2.2. Combined footing [Strap beam may

or may not be provided]

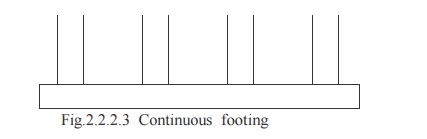

(iii) Continuous Footings: If a footing is common to more than two columns in a row, it is called continuous footing. This type of footing is necessary, if the columns in a row are closer or if SBC of soilis low. Figure 2.2.2.3shows this type of footing.

Fig.2.2.2.3

Continuous footing

(iv) Mat Footing/Raft

Footing: If the load on the column is quite high

(Multistorey columns) or when the SBC of soil is low, the sizes of

isolated columns may work out to be to such an extent that they overlap each

other. In such situation a common footing may be provided to several columns as

shown in Fig. 2.2.2.4 Such footings are known as raft footings.

If the beams are provided in both directions

over the footing slab for connecting columns, the raft foundations may be

called as grid foundation also.

The added advantage of such footing is,

settlement is uniform and hence unnecessary stresses are not produced.

Fig.2.2.2.4 Raft foundation

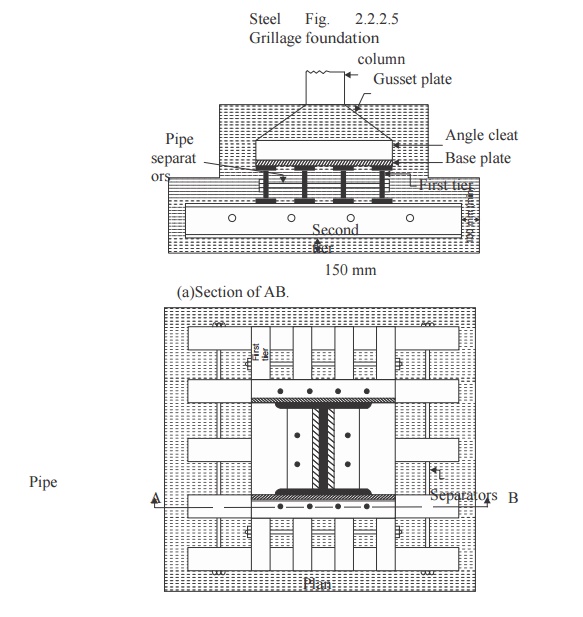

Grillage footing

High rise buildings are built with steel columns

encased in concrete. Such columns carry very heavy load and hence they need

special foundations to spread the load to a larger area of soil. Grillage

foundation is one such special foundation. It consists of one tier or more

tiers of I-sections steel beams. Fig 2.2.2.5 shows a typical two tier grillage

foundation. Top tier consists of less number but large size steel section while

lower tier consists of larger number but smaller size steel sections. Column

load is transferred to the top tier through a base plate. The grillage beams

are unpainted and are encased in concrete with minimum cover of 100 mm beyond

the edges of steel sections. A minimum clear space of 75 mm should be

maintained between the flanges of adjacent grillage beams so that concreting

can be made properly.To maintain spacing, pipe separators are used.

Steel Fig. 2.2.2.5 Grillage foundation

Related Topics