Chapter: Environmental Biotechnology: Pollution and Pollution Control

Biotrickling filters - Practical Applications to Pollution Control

Biotrickling filters

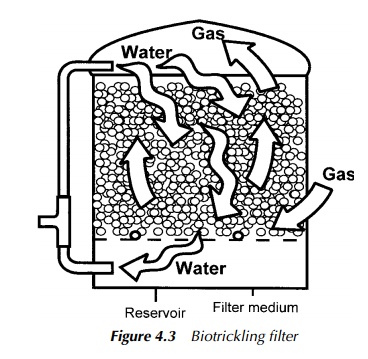

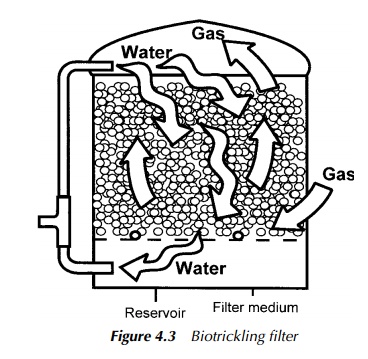

As shown in Figure 4.3, in many respects these represent an

intermediate tech-nology between biofilters and bioscrubbers, sharing certain

features of each. Once again, an engineered vessel holds a quantity of filter

medium, but in this case, it is an inert material, often clinker or slag. Being

highly resistant to compaction, this also provides a large number of void

spaces between particles and a high surface area relative to the overall volume

of the filter. The microbes form an attached growth biofilm on the surfaces of

the medium. The odourous air is again forced through the filter, while water

simultaneously recirculates through it, trickling down from the top, hence the

name. Thus a counter-current flow is established between the rising gas and the

falling water, as shown in the diagram, which improves the efficiency of

dissolution. The biofilm communities feed on substances in the solution passing

over them, biodegrading the constituents of the smell.

Process monitoring can be

achieved relatively simply by directly sampling the water recirculating within

the filter vessel. Process control is similarly straight-forward, since

appropriate additions to the circulating liquid can be made, as required, to

ensure an optimum internal environment for bacterial action. Though the

efficiency of the biotrickling filter is broadly similar to the previous

method, it can deal with higher concentrations of contaminant and has a

significantly smaller foot-print than a biofilter of the same throughput

capacity. However, as with almost all aspects of environmental biotechnology,

these advantages are obtained by means of additional engineering, the corollary

of which is, inevitably, higher capital and running costs.

Related Topics