Chapter: Environmental Biotechnology: Pollution and Pollution Control

Biofilters - Practical Applications to Pollution Control

Biofilters

As mentioned earlier, these were the first methods to be developed.

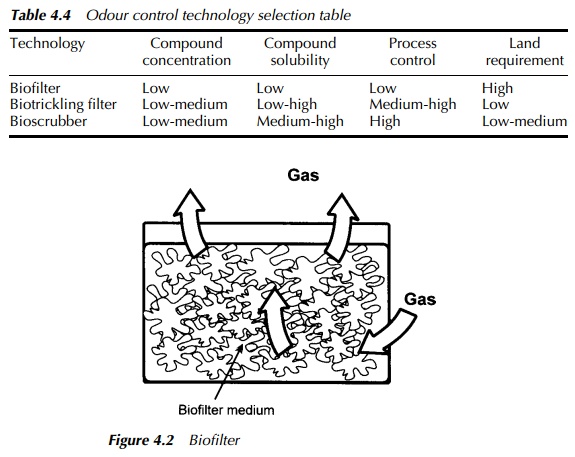

The system, shown schematically in Figure 4.2, consists of a relatively large

vessel or container, typically made of cast concrete, metal or durable

plastic, which holds a filter medium of organic material such as peat, heather,

bark chips and the like. The gas to be treated is forced, or drawn, through the

filter, as shown in the diagram. The medium offers good water-holding capacity and

soluble chemicals within the waste gas, or smelt, dissolve into the film of

moisture around the matrix. Bacteria, and other micro-organisms present,

degrade components of the resultant solution, thereby bringing about the

desired effect. The medium itself provides physical support for microbial

growth, with a large surface area to vol-ume ratio, high in internal void

spaces and rich in nutrients to stimulate and sustain bacterial activity.

Biofilters need to be watered sufficiently to maintain optimum internal

conditions, but waterlogging is to be avoided as this leads to compaction, and

hence, reduced efficiency. Properly maintained, biofilters can reduce odour

release by 95% or more.

Related Topics