Chapter: Mechanical and Electrical : Power Plant Engineering : Steam Power Plants

Surface Condenser

SURFACE CONDENSER

In surface condensers there is no

direct contact between the steam and cooling water and the condensate can be

re-used in the boiler. In such a condenser even impure water can be used for

cooling purpose whereas the cooling water must be pure in jet condensers. Although

the capital cost and the space needed is more in surface condensers but it is

justified b the saving in running cost and increase in efficiency of plant

achieved by using this condenser. Depending upon the position of condensate

extraction pump, flow of condensate and arrangement of tubes the surface

condensers may be classified as follows:

1. Down flow

condenser

2. Central

flow condenser

3. Evaporative

condenser

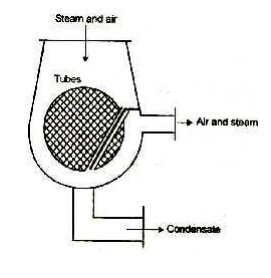

1.Down flow condenser

Figure shows a sectional view of

down flow condenser. Steam enters at the top and flows downward. The water

flowing through the tubes in one direction lower half comes out in the opposite

direction in the upper half. In this type of condenser, the cooling water and

exhaust steam do not come in direct contact with each other as in case of jet

condensers.

This is generally used where

large quantities of inferior water are available and better quantity of feed

water to the boiler must be used most economically. The arrangement of the

surface condenser is shown in figure. It consists of cast iron air- tight

cylindrical shell closed at each end as shown in figure. A number of water

tubes are fixed in the tube plates which are located between each cover head

and shell.

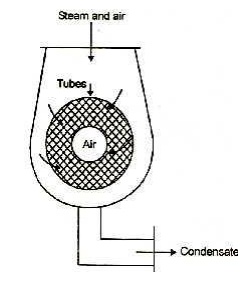

2. Central flow condenser.

Figure shows a central flow

condenser. In this condenser the steam passages are all around the periphery of

the shell. Air is pumped away from the centre of the condenser. The condensate

moves radially towards the centre of the tube next. Some of the exhaust steam

which moving towards the centre meets the under cooled condensate and pre-heats

it thus reducing under cooling.

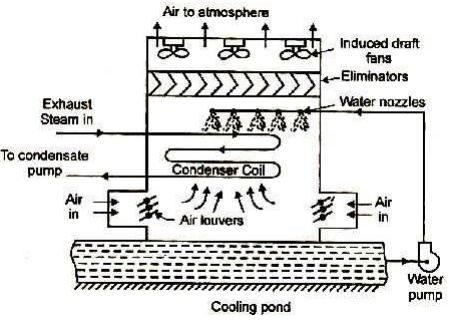

3. Evaporative condenser

In this condenser steam to be

condensed in passed through a series of tubes and the cooling water falls over

these tubes in the form of spray. A steam of air flows over the tubes to

increase evaporation of cooling water which further increases the condensation

of steam.

These condensers are more

preferable where acute shortage of cooling water exists. The arrangement of the

condenser is shown in figure. Water is sprayed through the nozzles over the

pipe carrying exhaust steam and forms a thin film over it. The air is drawn

over the surface of the

Related Topics