Chapter: Mechanical : Design of Machine Elements : Steady Stresses and Variable Stresses In Machine Members

Steady Stresses and Variable Stresses In Machine Members

STEADY STRESSES AND VARIABLE STRESSES IN MACHINE MEMBERS

Load

It is defined as any external force acting upon a machine part. The

following four types of the load are important from the subject point of view:

Dead or

steady load. A load is said to be a dead or steady load, when it

does not change in magnitude or direction.

Live or

variable load.A load is said to be a live or variable load, when

it changes continually.

Suddenly

applied or shock loads. A load is said to be a suddenly applied or shock

load, when it is suddenly applied or removed.

Impact

load. A load is said to be an impact load, when it is applied with some

initial velocity.

Stress

When some external system of forces or loads act on

a body, the internal forces (equal and opposite) are set up at various sections

of the body, which resist the external forces. This internal force per unit

area at any section of the body is known as unit stress or simply a stress. It is

denoted by a Greek letter sigma (σ).

Mathematically,

Stress,

σ = P/A

where P = Force or load acting on a body, and A =

Cross-sectional area of the body.

Strain

When a system of forces or loads act on a body, it undergoes some

deformation. This deformation per unit length is known as unit

strain or simply a strain. It is denoted by a Greek letter

epsilon (ε).

Mathematically,

Strain, ε = δl / l or δl = ε.l where δl = Change in length of

the body, and

l =

Original length of the body.

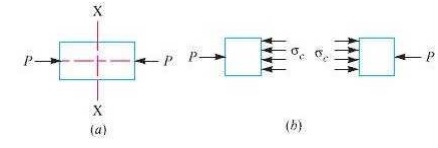

Tensile

Stress and Strain

When a

body is subjected to two equal and opposite axial pulls P (also called tensile

load) as shown in Fig. (a), then the stress induced at any section of the body

is known as tensile stress as shown in Fig. (b). A little

consideration will show that due to the tensile load, there will be a decrease

in cross-sectional area and an increase in length of the body. The ratio of the

increase in length to the original length is known as tensile

strain.

Let P =

Axial tensile force acting on the body,

A =

Cross-sectional area of the body,

l =

Original length, and

δl =

Increase in length.

Tensile

stress, σt = P/A

Tensile strain, εt = δl / l

Compressive

Stress and Strain

When a

body is subjected to two equal and opposite axial pushes P (also called

compressive load) as shown in Fig.(a), then the stress induced at any section

of the body is known as compressive stress as shown

in Fig.(b). A little consideration will show that due to the compressive

load, there will be an increase in cross-sectional area and a decrease in

length of the body. The ratio of the decrease in length to the original length

is known as compressive strain

Let P =

Axial compressive force acting on the body,

A =

Cross-sectional area of the body,

l =

Original length, and

δl =

Decrease in length.

Compressive

stress, σc = P/A

Compressive strain, εc = δl /l

Young's

Modulus or Modulus of Elasticity

Hooke's law states that when a material is

loaded within elastic limit, the stress is directly proportional to strain, i.e.

∝ ε

= E.ε

E

= σ / ε

=

P l / (A×δ l)

Where E

is a constant of proportionality known as Young's modulus or modulus of

elasticity. In S.I. units, it is usually expressed in GPa i.e.

GN/m2 or kN/mm2. It may be noted that Hooke's law holds

good for tension as well as compression.

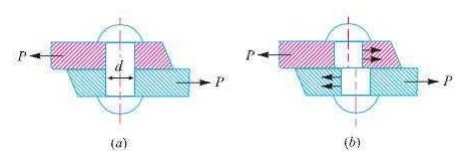

Shear

Stress and Strain

When a

body is subjected to two equal and opposite forces acting tangentially across

the resisting section, as a result of which the body tends to shear off the

section, then the stress induced is called shear stress.

The

corresponding strain is known as shear strain and it is measured by the angular

deformation accompanying the shear stress. The shear stress and shear strain

are denoted by the Greek letters tau (τ) and phi (φ) respectively.

Mathematically,

Shear

stress, τ

=Tangential force / Resisting area

Consider

a body consisting of two plates connected by a rivet as shown in Fig. (a). In

this case, the tangential force P tends to shear off the rivet at one

cross-section as shown in Fig.(b). It may be noted that when the tangential

force is resisted by one cross-section of the rivet (or when shearing takes

place at one cross-section of the rivet), then the rivets are said to be in single

shear. In such a case, the area resisting the shear off the rivet,

A

= (π/4) × d2

and shear

stress on the rivet cross-section,

= P/A

=

(4P/ π d2)

Shear Modulus or Modulus of Rigidity

It has

been found experimentally that within the elastic limit, the shear stress is

directly proportional to shear strain. Mathematically

∝ φ

= C . φ

/ φ = C

where

τ = Shear

stress,

φ = Shear

strain, and

C = Constant

of proportionality, known as shear modulus or modulus of rigidity. It is also

denoted by N or G.

Working

Stress

When

designing machine parts, it is desirable to keep the stress lower than the

maximum or ultimate stress at which failure of the material takes place. This

stress is known as the working

stress

Factor

of Safety

It is defined, in general, as the ratio of the

maximum stress to the working stress. Mathematically,

Factor

of safety = Maximum stress / Working or design stress

In case of ductile materials e.g. mild steel, where the yield point is

clearly defined, the factor of safety is based upon the yield point stress. In

such cases,

Factor

of safety = Yield point stress / Working or design stress

In case

of brittle materials e.g. cast iron, the yield point is not well defined as for

ductile materials. Therefore, the factor of safety for brittle materials is

based on ultimate stress.

Factor

of safety = Ultimate stress / Working or design stress

This

relation may also be used for ductile materials

Poisson's

Ratio

It has

been found experimentally that when a body is stressed within elastic limit,

the lateral strain bears a constant ratio to the linear strain, Mathematically,

Lateral

strain / Linear strain = Constant

This

constant is known as Poisson's ratio and is

denoted by 1/m or µ.

Bulk

Modulus

When a

body is subjected to three mutually perpendicular stresses, of equal intensity,

then the ratio of the direct stress to the corresponding volumetric strain is known

as bulk

modulus. It is usually denoted by K. Mathematically, bulk modulus,

K

= Direct stress / Volumetric strain

Relation

Between Bulk Modulus and Young’s Modulus

The bulk

modulus (K) and Young's modulus (E) are related by the following relation,

E=

3K (1 - 2 µ)

Relation

Between Young’s Modulus and Modulus of Rigidity

The

Young's modulus (E) and modulus of rigidity (G) are related by the following

relation,

E=

2G (1 + µ)

Resilience

When a body is loaded within elastic limit, it

changes its dimensions and on the removal of the load, it regains its original

dimensions. So long as it remains loaded, it has stored energy in itself. On

removing the load, the energy stored is given off as in the case of a spring.

This energy, which is absorbed in a body when strained within elastic limit, is

known as strain energy. The strain energy is always capable of doing some

work.

The strain energy stored in a body due to external

loading, within elastic limit, is known as resilience and the maximum energy which can

be stored in a body up to the elastic limit is called proof

resilience. The proof resilience per unit volume of a material is known as modulus

of resilience.

It is an important property of a material and gives capacity of the

material to bear impact or shocks. Mathematically, strain energy stored in a

body due to tensile or compressive load or resilience,

U=

(σ2 ×V) / 2E

Modulus

of resilience = σ2 / 2E

where σ = Tensile or compressive stress, V = Volume

of the body, and

= Young's modulus of the material of the body

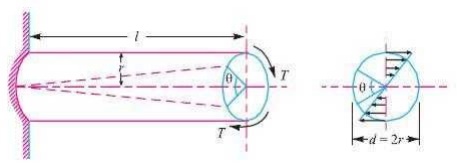

Torsional Shear Stress

When a

machine member is subjected to the action of two equal and opposite couples

acting in parallel planes (or torque or twisting moment), then the machine

member is said to be subjected to torsion. The stress set up by torsion is

known as torsional shear stress. It is zero at the centroidal

axis and maximum at the outer surface.

Consider a shaft fixed at one end and subjected to

a torque (T) at the other end as shown in Fig. As a result of this torque,

every cross-section of the shaft is subjected to torsional shear stress. We

have discussed above that the torsional shear stress is zero at the centroidal

axis and maximum at the outer surface. The maximum torsional shear stress at

the outer surface of the shaft may be obtained from the following equation:

(τ /r) = (T/J) = (Cθ/ l )

where

τ =

Torsional shear stress induced at the outer surface of the shaft or maximum

shear stress,

= Radius of the shaft,

= Torque

or twisting moment,

= Second

moment of area of the section about its polar axis or polar moment of inertia,

C =

Modulus of rigidity for the shaft material, l = Length of the shaft, and

= Angle of twist in radians on a length l.

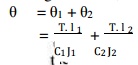

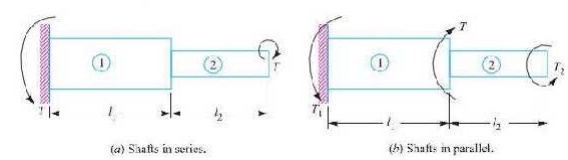

Shafts

in Series and Parallel

When two

shafts of different diameters are connected together to form one shaft, it is

then known as composite shaft. If the

driving torque is applied at one end and the resisting torque at the other end,

then the shafts are said to be connected in series as shown in Fig. (a). In

such cases, each shaft transmits the same torque and the total angle of twist

is equal to the sum of the angle of twists of the two shafts.

Mathematically,

total angle of twist,

If the

shafts are made of he same material,

then C1 = C2 = C.

When the driving torque (T) is applied at the

junction of the two shafts, and the resisting torques T1 and T2 at the other

ends of the shafts, then the shafts are said to be connected in parallel, as

shown in Fig. 5.2 (b). In such cases, the angle of twist is same for both the

shafts,

i.e.

If the

shafts are made of the same material, then C1 = C2.

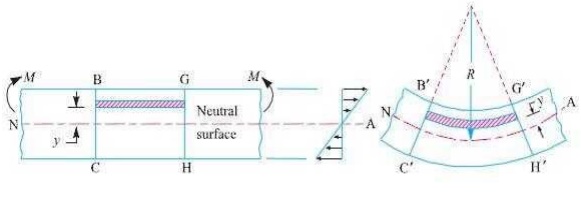

Bending

Stress in Straight Beams

In

engineering practice, the machine parts of structural members may be subjected

to static or dynamic loads which cause bending stress in the sections besides

other types of stresses such as tensile, compressive and shearing stresses.

Consider a straight beam subjected to a bending moment M as shown in Fig. The

following assumptions are usually made while deriving the bending formula.

The material of the beam is perfectly homogeneous

(i.e. of the same material throughout) and isotropic (i.e. of equal elastic

properties in all directions).

The material of the beam obeys Hooke’s law.

The transverse sections (i.e. BC or GH) which were

plane before bending, remain plane after bending also.

Each layer of the beam is free to expand or

contract, independently, of the layer, above or below it.

The Young’s modulus (E) is the same in tension and

compression.

The loads are applied in the plane of bending.

A little consideration will show that when a beam is subjected to the bending moment, the fibres on the upper side of the beam will be shortened due to compression and those on the lower side will be elongated due to tension. It may be seen that somewhere between the top and bottom fibres there is a surface at which the fibres are neither shortened nor lengthened. Such a surface is called neutral surface. The intersection of the neutral surface with any normal cross-section of the beam is known as neutral axis. The stress distri bution of a beam is shown in Fig. The bending equation is given by

where M = Bending moment acting at the given

section, σ = Bending stress,

I =

Moment of inertia of the cross-section about the neutral axis, y = Distance

from the neutral axis to the extreme fibre,

E =

Young’s modulus of the material of the beam, and R = Radius of curvature of the

beam.

Related Topics