Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Manufacturing Operations

Manufacturing Operations: Processing and Assembly Operations

MANUFACTURING OPERATIONS

There are certain basic activities that must be

carried out in a factory to convert raw materials into finished products.

Limiting our scope to a plant engaged in making discrete products, the factory

activities are: (1) processing and assembly operations, (2) material handling,

(3) inspection and test, and (4) coordination and control.

The first three activities

are the physical activities that “touch” the product as it is being made.

Processing and assembly operations alter the geometry, properties, and/or

appearance of the work unit. They add value to the product. The product must be

moved from one operation to the next in the manufacturing sequence, and it must

be inspected and/or tested to insure high quality. It is sometimes argued that

these material handling and inspection activities not add value to the product.

However, our viewpoint is that value is added through the totality of

manufacturing operations performed on the product. Unnecessary operations,

whether they are processing, assembly, material handling, or inspection, must

be eliminated from the sequence of steps performed to complete a given product.

1

Processing and Assembly Operations

Manufacturing processes can be divided into two

basic types: (1) processing operations and (2) assembly operations. A processing operation transforms a work

material from one state of completion to a more advanced state that is closer

to the final desired part or product. It adds value by changing the geometry,

properties, or appearance of the starting material. In general, processing

operations are performed on discrete workparts, but some processing operations

are also applicable to assembled items, for example, painting a welded sheet

metal car body. An assembly operation

joins two or more components to create a new entity, which is called an

assembly, subassembly, or some other term that refers to the specific joining

process.

Processing

Operations. A processing

operation uses energy to alter a workpart’s shape, physical properties, or appearance to add value to the

material. The forms of energy include mechanical, thermal, electrical, and

chemical. The energy is applied in a controlled way by means of machinery and

tooling. Human energy may also be required, but human workers are generally

employed to control the machines, to oversee the operations, and to load and

unload parts before and after each cycle of operation. A general model of a

processing operation is illustrated in Figure 2.1(a). Material is fed into the

process, energy is applied by the machinery and tooling to transform the

material, and the completed workpart exits the process. As shown in our model,

most production operations produce waste or scrap, either as a natural

byproduct of the process (e.g., removing material as in machining) or in the

form of occasional defective pieces. An important objective in manufacturing is

to reduce waste in either of these forms.

More than one processing

operation are usually required to transform the starting material into final

form. The operations are performed in the particular sequence to achieve the

geometry and/or condition defined by the design specification.

Three categories of processing operations are

distinguished: (1) shaping operations,

(2) property–enhancing operations, and (3)

surface processing operations. Shaping

operations apply mechanical force or heat or other forms and combinations

of energy to effect a change in

geometry of the work material.There are various ways to classify these

processes. The classification used here is based on the state of the starting

material, by which we have four categories:

1. Solidification

processes. The

important processes in this category are

casting (for metals) and molding (for plastics and glasses), in

which the starting material is a heated liquid or semifluid, in which state it

can be poured or otherwise forced to flow into a mold cavity where it cools and

solidifies, taking a solid shape that is the same as the cavity.

2. Particulate

processing. The starting material is a

powder. The common technique involves pressing

the powders in a die cavity under high pressure to cause the powders to take

the shape of the cavity. However, the compacted workpart lacks sufficient

strength for any useful application. To increase strength, the part is then sintered— heated to a temperature below

the melting point, which causes the individual particles to bond together. Both

metals (powder metallurgy) and ceramics can be formed by particulate

processing.

Deformation

processes. In most cases, the starting

material is a ductile metal that is shaped

by applying stresses that exceed the metal’s yield strength. To increase

ductility, the metal is often heated prior to forming. Deformation processes

include forg ing, extrusion, and rolling.Also

included in this category are sheet metal processes such as drawing, forming, and bending.

4. Material

removal processes. The

starting material is solid (commonly a metal, ductile or brittle), from which excess material is removed from the

starting workpiece so that the resulting part has the desired geometry. Most

important in this category are machining operations

such as turning, drilling, and milling,

accomplished using cutting tools that

are harder and stronger than the work metal. Grinding is another common process in this category, in which an

abrasive grinding wheel is used to remove material. Other material removal

processes are known as nontraditional

processes because they do not use traditional cutting and grinding tools.

Instead, they are based on lasers, electron beams, chemical erosion, electric

discharge, or electrochemical energy.

Property–enhancing operations are designed to improve mechanical or physical properties of the

work material. The most important property–enhancing operations involve heat treatments,

which include various temperatureinduced strengthening and/or toughening processes for metals and glasses. Sintering of powdered metals and ceramics,

mentioned previously, is also a heat treatment, which strengthens a pressed

powder workpart. Propertyenhancing operations do not alter part shape, except

unintentionally in some cases, for example, warping of a metal part during heat

treatment or shrinkage of a ceramic part during sintering.

Surface processing operations include: (1) cleaning, (2) surface treatments, and (3) coating and thin film deposition

processes. Cleaning includes both

chemical and mechanical processes to remove dirt, oil, and other contaminants

from the surface. Surface treatments include

mechanical working, such as shot peening and sand blasting, and physical processes, like diffusion and ion

implantation. Coating and thin film deposition processes apply a

coating of material to the exterior surface of the workpart. Common coating

processes include electroplating, anodizing of aluminum, and organic coating (call it painting). Thin film deposition processes include physical vapor deposition and chemical vapor deposition to form

extremely thin coatings of various substances. Several surface processing

operations have been adapted to fabricate semiconductor materials (most

commonly silicon) into integrated circuits for microelectronics. These

processes include chemical vapor deposition, physical vapor deposition, and

oxidation. They are applied to very localized areas on the surface of a thin

wafer of silicon (or other semiconductor material) to create the microscopic

circuit.

3. Assembly Operations. The second basic type of manufacturing

operation is assembly, in which two or more separate parts are joined to form a

new entity. Components of the new entity are connected together either

permanently or semipermanently. Permanent joining processes include welding, brazing, soldering, and adhesive bonding. They combine parts by

forming a joint that cannot be easily disconnected. Mechanical assembly methods are available to fasten two (or more)

parts together in a joint that can be conveniently disassembled. The use of threaded fasteners (e.g., screws, bolts,

nuts) are important traditional methods in this category. Other mechanical

assembly techniques that form a permanent connection include rivets, press fitting, and expansion

fits. Special assembly methods are used in electronics. Some of the methods

are identical to or adaptations of the above techniques. For example, soldering

is widely used in electronics assembly. Electronics assembly is concerned

primarily with the assembly of components (e.g., integrated circuit packages)

to printed circuit boards to produce the complex circuits used in so many of

today’s products.

2 Other

Factory Operations

Other activities that must be performed in the

factory include material handling and storage, inspection and testing, and

coordination and control.

Material

Handling and Storage. A means

of moving and storing materials between processing and/or assembly operations

is usually required. In most manufacturing plants, materials spend more time

being moved and stored than being processed. In some cases, the majority of the

labor cost in the factory is consumed in handling, moving, and storing

materials. It is important that this function be carried out as efficiently as

possible. In Part II of our book, we consider the material handling and storage

technologies that are used in factory operations.

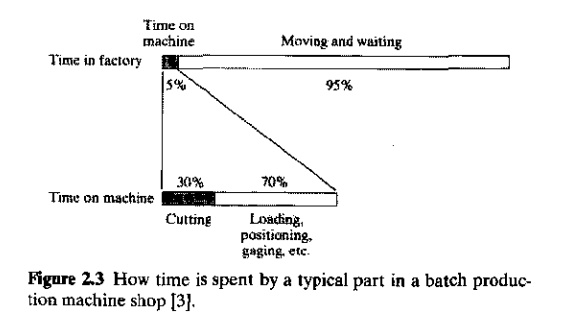

Eugene Merchant, an advocate

and spokesman for the machine tool industry for many years, observed that

materials in a typical metal machining batch factory or job shop spend more

time waiting or being moved than in processing [3]. His observation is illustrated

in Figure 2.3. About 95% of a part’s time is spent either moving or waiting

(temporary storage). Only 5% of its time is spent on the machine tool. Of this

5%, less than 30% of the time on the machine (1.5% of the total time of the

part) is time during which actual cutting is taking place. The remaining 70%

(3.5% of the total) is required for loading and unloading, part handling and

positioning, tool positioning, gaging, and other elements of nonprocessing

time. These time proportions provide evidence of the significance of material

handling and storage in a typical factory.

Inspection

and Test. Inspection and test are

quality control activities. The purpose of inspection

is to determine whether the manufactured product meets the established design

standards and specifications. For example, inspection examines whether the

actual dimensions of a mechanical part are within the tolerances indicated on

the engineering drawing for the part. Testing

is generally concerned with the functional specifications of the final product

rather than with the individual parts that go into the product. For example,

final testing of the product ensures that it functions and operates in the

manner specified by the product designer. In Part IV of this text, we examine

the inspection and testing function.

Coordination

and Control. Coordination

and control in manufacturing includes both the regulation of individual processing and assembly

operations as well as the management of plant level activities. Control at the

process level involves the achievement of certain performance objectives by

properly manipulating the inputs and other parameters of the process. Control

at the process level is discussed in Part I of the book.

Control at the plant level

includes effective use of labor, maintenance of the equipment, moving materials

in the factory, controlling inventory, shipping products of good quality on

schedule, and keeping plant operating costs at a minimum possible level..The

manufacturing control function at the plant level represents the major point of

intersection between the physical operations in the factory and the information

processing activities that occur in production. We discuss many of these plant

and enterprise level control functions in Parts IV and V.

Related Topics