Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Manufacturing Operations

Manufacturing Industries and Products

MANUFACTURING INDUSTRIES AND

PRODUCTS

Manufacturing

is an important commercial activity, carried out by companies that sell

products to customers. The type of manufacturing performed by a company depends

on the kinds of products it makes. Let us first take a look at the scope of the

manufacturing industries and then consider their products.

Manufacturing Industries. Industry consists of enterprises and

organizations that produce and/or supply goods and/or services. Industries can be

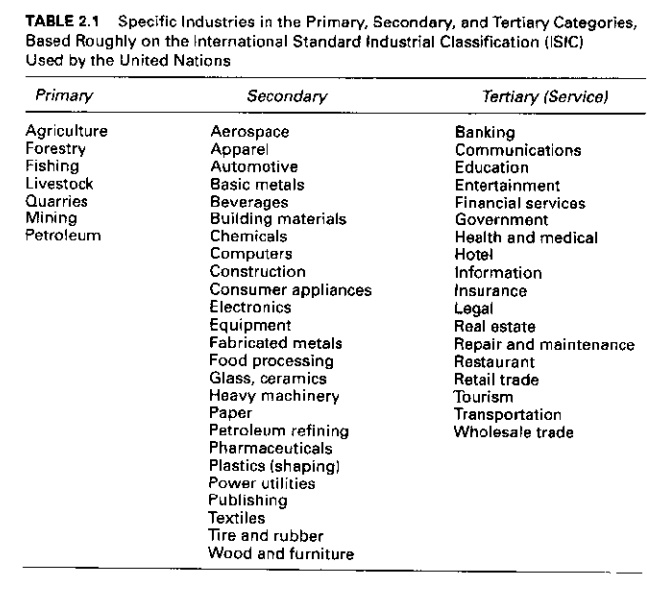

classified as primary, secondary, and tertiary. Primary industries are those that cultivate and exploit natural

resources, such as agriculture and mining. Secondary

industries convert the outputs of the primary industries into products.

Manufacturing is the principal activity in this category, but the secondary

industries also include construction and power utilities. Tertiary industries constitute the service sector of the economy. A

list of specific industries in these categories is presented in Table 2.1.

In this book, we are concerned with the secondary industries

(middle column in Table 2.1), which are composed of the companies engaged in

manufacturing. It is useful to distinguish the process industries from the

industries that make discrete parts and products. The process industries

include chemicals, pharmaceuticals, petroleum, basic metals, food, beverages,

and electric power generation. The discrete product industries include

automobiles, aircraft, appliances, computers, machinery, and the component

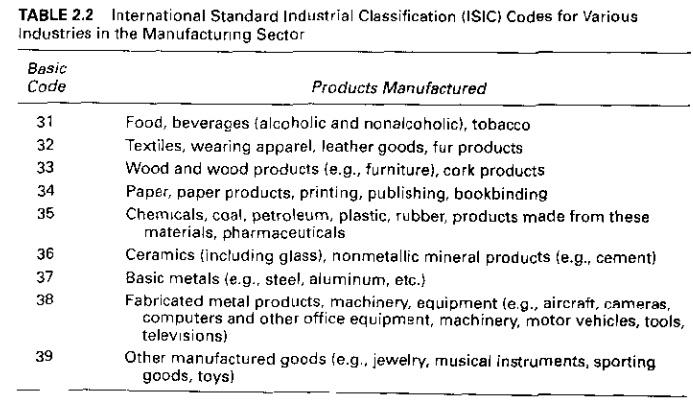

parts that these products are assembled from. The International Standard

Industrial Classification (ISIC) of industries according to types of products

manufactured is listed in Table 2.2. In general, the process industries are

included within ISIC codes 31–37, and the discrete product manufacturing

industries are included in ISIC codes 38 and 39. However, it must be

acknowledged that many of the products made by the process industries are

finally sold to the consumer in discrete units. For example, beverages are sold

in bottles and cans. Pharmaceuticals are often purchased as pills and capsules.

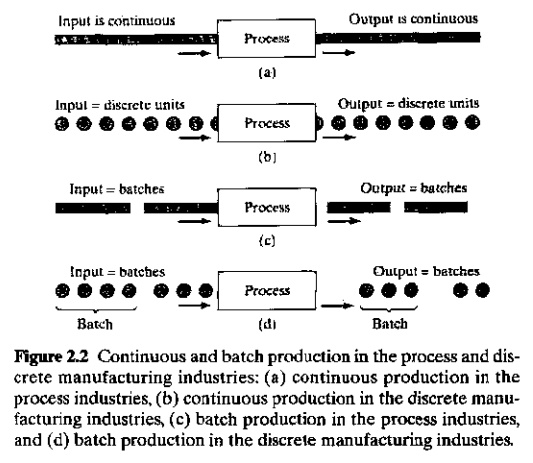

Production operations in the process industries and the discrete

product industries can be divided into continuous production and batch

production.The differences are shown in Figure 2.2. Continuous production occurs when the production equipment is used

exclusively for the given product, and the output of the product is uninterrupted.

In the process industries, continuous production means that the process is

carried out on a continuous stream of material, with no interruptions in the

output flow, as suggested by Figure 2.2(a) Once operating in steady state, the

process does not depend on the length of time it is operating. The material

being processed is likely to be in the form of a liquid, gas, powder, or

similar physical state. In the discrete manufacturing industries, continuous

production means 100% dedication of the production equipment to the part or

product, with no breaks for product changeovers. The individual units of

production are identifiable, as in Figure 2.2(b).

Batch production occurs when the materials are processed in

finite amounts or quantities. The finite amount or quantity of material is

called a batch in both the process

and discrete manufacturing industries. Batch production is discontinuous

because there are interruptions in production between batches. The reason for

using batch production is

TABLE 2.2 International

Standard Industrial Classification (ISIC) Codes for Various Industries in the Manufacturing Sector

because

the nature of the process requires that only a finite amount of material can be

accommodated at one time (e.g., the amount of material might be limited by the

size of the container used in processing) or because there are differences

between the parts or products made in different batches (e.g., a batch of 20

units of part A followed by a batch of 50 units of part B in a machining

operation, where a setup changeover is required between batches because of

differences in tooling and fixturing required). The differences in batch

production between the process and discrete manufacturing industries are

portrayed in Figure 2.2(c) and (d). Batch production in the process industries

generally means that the starting materials are in liquid or bulk form, and

they are processed altogether as a unit. By contrast, in the discrete

manufacturing industries, a batch is a certain quantity of work units, and the

work units are usually processed one at a time rather than altogether at once.

The number of parts in a batch can range from as few as one to as many as

thousands of units.

Manufactured Products. As indicated in Table 2.2, the secondary

industries include food, beverages, textiles, wood, paper, publishing,

chemicals, and basic metals (ISIC codes 31–39). The scope of our book is

primarily directed at the industries that produce discrete products (ISIC codes

38 and 39). The two groups interact with each other, and many of the concepts

and systems discussed in the book are applicable to the process industries, but

our attention is mainly on the production of discrete hardware, which ranges

from nuts and bolts to cars, airplanes, and digital computers. Table 2.3 lists

the manufacturing industries and corresponding products for which the

production systems in this book are most applicable.

Final products made by the industries listed in Table 2.3 can be

divided into two major classes: consumer goods and capital goods. Consumer goods are products purchased

directly by consumers, such as cars, personal computers, TVs, tires, toys, and

tennis rackets. Capital goods are

products purchased by other companies to produce goods and supply services.

Examples of capital goods include commercial aircraft, mainframe computers,

machine tools, railroad equipment, and construction machinery.

In addition to final products, which are usually assembled, there

are companies in industry whose business is primarily to produce materials, components, and supplies for the companies that make the

final products. Examples of these items include sheet steel, bar stock, metal

stampings, machined parts, plastic moldings and extrusions, cutting tools,

dies, molds, and lubricants. Thus, the manufacturing industries consist of a

complex infrastructure with various categories and layers of intermediate

suppliers that the final consumer never deals with.

Related Topics